|

|

|

|

• EC • Caustic Embrittlement • Intergranular • SSC • LME • MIC • SCC • HB-HE-HIC-HMx-HTHA• Sulfidation • NAC • Erosion • Fretting • Stray Current • Index |

|

Different Types of

Corrosion

|

|

Naphthenic Acid Corrosion (NAC) |

|

|

|

|

|

Naphthenic Acid Corrosion is a form of high temperature corrosion that occurs primarily in crude and vacuum units, and downstream units that process certain fractions or cuts that contain naphthenic acids. Naphthenic acid corrosion is strongly influenced by the following critical factors:

High temperature sulfidic corrosion (sulfidation) occurs in the temperature range that overlaps naphthenic acid corrosion. As virtually all crude oils have some sulfur, the effects of sulfidic corrosion (or sulfidation) and naphthcnic acid corrosion can be compounded.

|

|

|

Mechanisms of Naphthenic Acid Corrosion (NAC) |

|

|

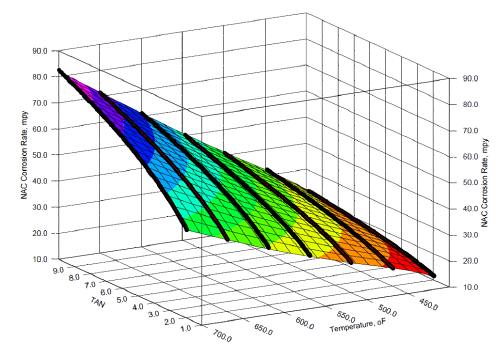

NAC is a function of the naphthenic acid content (neutralization number), temperature, sulfur content, velocity and alloy composition. Severity of corrosion increases with increasing acidity of the hydrocarbon phase. NAC normally occurs in hot streams above 425oF (218oC) but has been reported as low as 350oF (177oC). Severity increases with temperature up to about 750oF (400oC), however, NAC has been observed in hot coker gas oil streams up to 800oF (427oC).

There were thee naphthenic acid corrosion

mechanisms reported in the literature:

Depending on the prevailing operating conditions, oil soluble iron naphthenates may be produced and may wash away, or a sulfide precipitate may bed formed on the carbon steel or low alloy surface. If there is sufficient H2S in the system with favorable process conditions, the a protective sulfide film may form and offer some degree of protection against naphthenic acid corrosion. Under these conditions, corrosion is expected to be moderate, manifesting as general wall loss leaving behind a sulfide film on the surface of affected equipment. If there is insufficient H2S present or the process conditions such as high velocities are not conducive to sulfide film formation and adherence, then naphthenic acid corrosion will become predominant. With naphthenic acid corrosion dominating, any protective surface film that forms will be washed away, leading to high corrosion rates.

|

|

|

Modeling, Prediction and Prevention of Naphthenic Acid Corrosion |

|

|

How to determine the operating temperature limits for carbon steels, low alloy steels, and stainless steels in high temperature naphthenic acid corrosion? How

to select metallurgies for high temperature naphthenic acid corrosion resistance?

NAC-Compass software provides instant answers to the above questions. NAC-Compass is a powerful software for modeling and prediction of high naphthenic acid corrosion. Click this link for details on NAC-Compass.

|

|

|

For more details on Naphthenic Acid Corrosion (NAC) |

|

|

Where can I learn more about naphthenic acid corrosion? More details on naphthenic acid corrosion are included in the following corrosion courses which you can take as in-house training courses, course-on-demand, online courses or distance learning courses:

If you require corrosion expert witness or corrosion consulting service on naphthenic acid corrosion, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

| Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2025.. All rights reserved. |