|

|

|

|

• EC • Season Cracking • SSC • LME • MIC • SCC • Electrolysis • Electrolytic Corrosion • AC Corrosion • Stray Current • Index |

|

Different Types of

Corrosion

|

|

Stray Current Corrosion |

|

|

Recognition of Stray Current Corrosion |

|

|

How to identify stray current corrosion? Stray current is a dynamic and transient phenomenon. Corrosion ONLY occurs at the point of discharge (POD). At the point of entry (POE) and along the entire system that carries the stray current, there is NO corrosion. In fact, at the point of entry, stray current provides certain degrees of cathodic protection to the metallic structure.

Among the many different types of corrosion, stray current corrosion is probably the most misused term by unqualified corrosion consultants worldwide who literally refer to any corrosion phenomenon beyond their comprehension as stray current corrosion. This mis-diagnosis often results in significant financial losses and safety lapses for facility owners and operators.

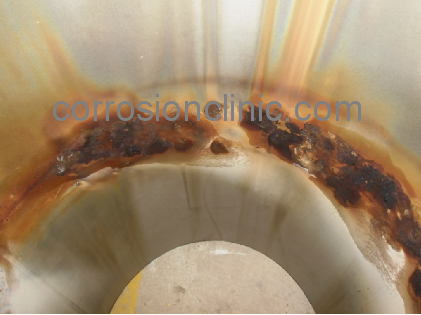

The photo on the right was misdiagnosed as stray current corrosion by a "corrosion consultant" from a reputable company in Europe. The facility owner incurred significant cost and wasted a lot of time trying to measure the elusive stray current in the surroundings. A NACE certified Corrosion Specialist can pinpoint the cause of corrosion and rule out any possibility of stray current corrosion simply based on the visual inspection of the corroded component.

Accurate identification of stray current corrosion requires a sound understanding of all types of corrosion. A qualified corrosion consultant (NACE certified Corrosion Specialist) can tell the differences among the different types of corrosion. Stray current corrosion is fundamentally different from other (non-stray current) types of corrosion in that stray current corrosion is an electrolysis process. In the electrolysis process, the external current (stray current) alone drives metal atoms into electrolyte as water-soluble ions. The environmental factors such as oxygen concentration, chloride, and pH that are so critical to natural corrosion processes are no longer relevant. The extent of damage or loss of metal is directly proportional to the magnitude of stray current leaving the structure at the point of discharge. Stray current corrosion will be concentrated at certain location that leads to the lowest electrical resistance in the current circuit.

What structures are affected by stray current corrosion? All metallic structures buried or immersed are susceptible to stray current corrosion. DC railways, tunnels, underground pipelines, and storage tanks without CP systems are particularly susceptible to stray current corrosion. Stray current corrosion tends to be localized at locations where the stray current leaves the metal structure and enters the electrolyte (soil/concrete/water).

Does AC current cause corrosion? Long term AC interference on a buried or immersed pipeline can also cause corrosion on the steel surface at coating defects. Among other things, corrosion damage depends on A.C. current density, level of D.C. polarisation, coating defect geometry, local soil composition and soil resistivity. AC corrosion of metallic pipelines is not uncommon in the pipeline industry. AC interferences can be caused by inductive, conductive or capacitive coupling with AC power systems.

|

|

|

Mechanisms of Stray Current Corrosion |

|

|

What causes Stray current corrosion? Stray current corrosion is different from natural corrosion because it is caused by an external electrical current and is basically independent of such environmental factors as oxygen concentration, chloride or pH. Environmental factors may enhance other corrosion mechanisms involved in the total corrosion process, but the stray current corrosion portion of the mechanism is unaffected.

What are the differences among stray current corrosion, stray current electrolysis, electrolytic corrosion, and galvanic corrosion?

As per ASTM and NACE standards, electrolysis refers to the production of chemical changes of the electrolyte by the current flowing through an electrochemical cell. Stray current corrosion is an electrolysis process.

ASTM and NACE standards further state that electrolytic corrosion is not a proper term, but sometimes incorrectly used by some casual authors to refer to galvanic corrosion, stray current corrosion, or any form of electrochemical corrosion.

Some authors incorrectly state that stray current corrosion is similar to galvanic corrosion when in fact the two processes are fundamentally different. In stray current corrosion, the driving force for corrosion is an external electrical current that is virtually unlimited in its magnitude depending on its source; while in galvanic corrosion, there is no external electrical current involved, the driving force for galvanic corrosion is the potential difference (voltage) between the two dissimilar metals. The galvanic current is internally generated (like in an alkaline battery) and is very much limited in its magnitude. This means that the potential damage by stray current corrosion can be many times greater than that by galvanic corrosion.

What are the sources of stray current? Where does stray current come from? Stray current may originate from the following sources:

|

|

|

Prevention and Prediction of Stray Current Corrosion |

|

|

How to prevent stray current corrosion? Stray current corrosion can be prevented through:

How to predict stray current corrosion? Stray current corrosion can be predicted using software such as "SC-Compass: Stray Current Corrosion - Identification, Assessment and Prediction". Click the link for details on the software.

|

|

|

For more details on Stray Current Corrosion |

|

|

Where can I learn more about stray current corrosion? More details on stray current corrosion are included in the following corrosion courses which you can take as in-house training courses, course-on-demand, online courses or distance learning courses:

If you require corrosion expert witness or corrosion consulting service on stray current corrosion, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

|

Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2026.. All rights reserved. |