|

|

|

|

• EC • Season Cracking • SSC • LME • MIC • SCC • Electrolysis • Electrolytic Corrosion • Stray Current • AC Corrosion • Index |

|

Different Types of

Corrosion

|

|

AC Corrosion of Underground Pipelines |

|

|

Recognition of AC Corrosion of Underground Pipelines |

|

|

AC Corrosion refers to corrosion initiated and propagating under the influence of alternating current. A.C. voltage on a buried or immersed pipeline is the driving force for the A.C. corrosion taking place on the steel surface at coating defects. Among other things, corrosion damage depends on A.C. current density, level of D.C. polarisation, defect geometry, local soil composition and resistivity. Long term A.C. interference on a buried or immersed pipeline can also affect the operation of cathodic protection systems.

What structures are affected by AC corrosion? Buried or immersed pipelines are susceptible to AC corrosion. Soil and water act as effective electrolyte in the AC corrosion process.

|

|

|

Mechanisms of AC Corrosion |

|

|

What causes AC corrosion? For pipelines with cathodic protection applied in accordance with usual criteria, the development of AC corrosion requires simultaneous co-existence of induced AC, excessive cathodic protection, and small coating defects. The induced AC will lead to the discharge of AC current at coating defects. The AC current density will be governed by the AC voltage (coating stress voltage) and the spread resistance which is influenced by the size of the coating defect, the soil resistivity at the coating defect, the chemistry of the soil, and by the cathodic protection current density in the coating defect.

The AC current density may lead to DC depolarization. This means that a higher CP (DC) current density is required to maintain a certain cathodic protection potential.

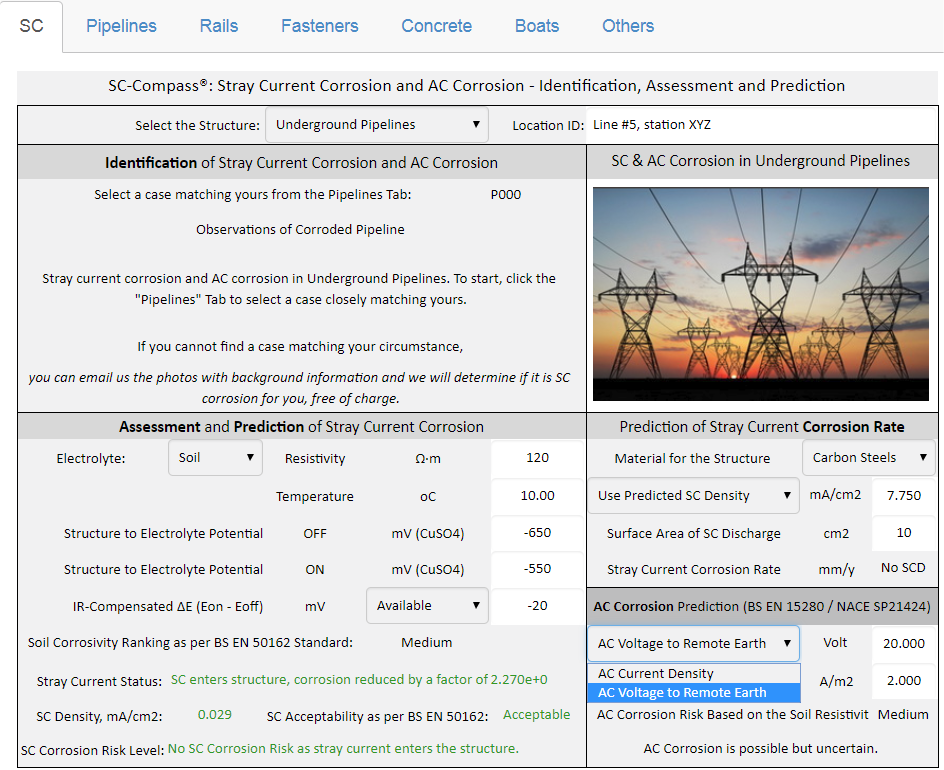

Computer software such as SC-Compass has a module on AC corrosion assessment and prediction taking into consideration of the electrolyte resistivity, AC voltage, AC current density, or AC current to DC current ratio. Refer to the next section on AC corrosion assessment and prediction for details.

What is the difference between AC corrosion and stray current corrosion? There are a number of differences between AC corrosion and stray current corrosion:

What are the sources of AC current? Where does AC current come from? AC interferences can be caused by inductive, conductive or capacitive coupling with AC power systems.

|

|

|

Prevention and Prediction of AC Corrosion |

|

|

How to prevent AC corrosion? AC corrosion can be effectively prevented through:

How to predict AC corrosion? AC corrosion can be predicted using software such as "SC-Compass: Stray Current Corrosion - Identification, Assessment and Prediction". Click the link for details on the software.

|

|

|

For more details on AC Corrosion |

|

|

Where can I learn more about AC corrosion? More details on AC corrosion are included in the following corrosion courses which you can take as in-house training courses, course-on-demand, online courses or distance learning courses:

If you require corrosion expert witness or corrosion consulting service on AC corrosion, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

|

Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2025.. All rights reserved. |

What is AC corrosion?

What is AC corrosion?  How to identify AC corrosion?

AC corrosion on buried or immersed

pipelines occurs at coating defects. A hard ball of deposit often covers a

shallow pit at the coating defect. Small circular dimples are often found in

the pit.

How to identify AC corrosion?

AC corrosion on buried or immersed

pipelines occurs at coating defects. A hard ball of deposit often covers a

shallow pit at the coating defect. Small circular dimples are often found in

the pit.