|

|

|

|

• EC • Season Cracking • Caustic Embrittlement • SSC • LME • MIC • SCC • HB-HE-HIC • Fatigue • Erosion • Fretting • Stray Current • Index |

|

Different Types of

Corrosion

|

|

Liquid Metal Embrittlement |

|

|

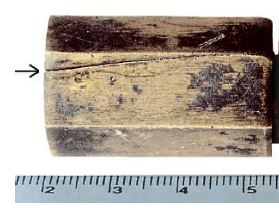

Recognition of Liquid Metal Embrittlement |

|

|

What is liquid metal embrittlement? Liquid Metal Embrittlement (LME) refers to environmental cracking caused by contact with a liquid metal. It is also known or as Liquid Metal Cracking (LMC).

Mercury-containing items are prohibited by all airlines as they pose a real risk to the structural integrity of the aircraft which is made of aluminum alloys.

Zinc from galvanized steel parts or zinc-rich paints is frequently found to be responsible for the cracking of welded steel components in various industries.

|

|

|

Mechanisms of Liquid Metal Embrittlement |

|

|

What causes liquid metal cracking? The mechanism of liquid metal cracking is clearly not electrochemical in nature. It is most probably an adsorption-induced cracking. The liquid metal atoms when adsorbed on a susceptible metal or alloy reduces the metal bond strength within the grain boundary regions of the susceptible metal. Under tensile stress, crack initiates and propagates rapidly along the grain boundaries.

|

|

|

Prevention of Liquid Metal Embrittlement |

|

|

How to prevent liquid metal cracking? Liquid metal cracking can be prevented through:

|

|

|

For more details on Liquid Metal Embrittlement |

|

|

Where can I learn more about liquid metal embrittlement? More details on liquid metal cracking are included in the following corrosion courses which you can take as in-house training courses, course-on-demand, online courses or distance learning courses:

If you require corrosion expert witness or corrosion consulting service on liquid metal embrittlement (LME), our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

|

Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2026.. All rights reserved. |

There is a specific combination of

There is a specific combination of