|

|

|

|

• EC • Season Cracking • Caustic Embrittlement • SCC • SSC • LME • HB-HE-HIC-HMx • Fatigue • Erosion • Fretting • Stray Current • Index |

|

Different Types of

Corrosion

|

|

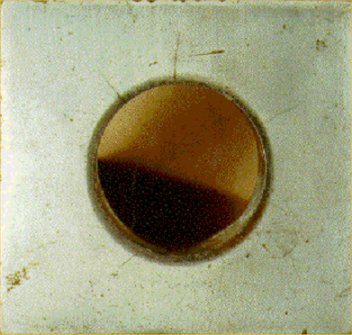

Caustic Embrittlement (Caustic Cracking) |

|

|

Recognition of Caustic Embrittlement |

|

|

|

|

|

Mechanisms of Caustic Embrittlement |

|

|

What causes caustic embrittlement? Caustic embrittlement results from the conjoint action of three components:

Caustic soda (NaOH) was added in small amounts to boiler water to prevent scaling but the presence of caustics (alkalis), usually concentrated in crevices around rivet heads and at hot spots, combined with the considerable fabrication stresses around rivet holes to caused cracking of the steel boiler shells and tube plates.

|

|

|

Prevention of Caustic Embrittlement |

|

|

How to prevent caustic embrittlement? Caustic embrittlement can be prevented through:

|

|

|

For more details on Caustic Embrittlement |

|

|

Where can I learn more about caustic embrittlement? More details on caustic embrittlement are included in the following corrosion short courses which you can take as in-house training courses, course-on-demand, online courses or distance learning courses:

If you require corrosion expert witness or corrosion consulting service on caustic embrittlement, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

|

Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2026.. All rights reserved. |