|

|

|

|

• EC • Season Cracking • Caustic Embrittlement • Intergranular • SSC • LME • MIC • SCC • HB-HE-HIC • Fatigue • Erosion• Stray Current • Index |

|

Different Types of

Corrosion

|

|

Stress Corrosion Cracking (SCC) |

|

|

Recognition of Stress Corrosion Cracking |

|

|

What is stress corrosion cracking?

Stress-corrosion cracking (SCC) is a cracking process that requires

the simultaneous action of a corrodent and sustained

tensile stress. This

excludes corrosion-reduced sections

that fail by fast fracture. It also

excludes intercrystalline or transcrystalline corrosion, which can

disintegrate

an alloy without

|

|

|

Mechanisms of Stress

Corrosion Cracking |

|

|

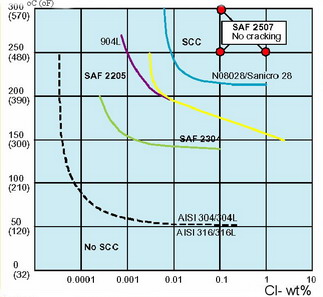

What causes stress corrosion cracking? Stress corrosion cracking results from the conjoint action of three components: (1) a susceptible material; (2) a specific chemical species (environment) and (3) tensile stress. For example, copper and its alloys are susceptible to ammonia compounds, mild steels are susceptible to alkalis and stainless steels are susceptible to chlorides. There is no unified mechanism for stress corrosion cracking in the literature. Various models have been proposed which include the following:

|

|

|

Prevention of Stress

Corrosion Cracking |

|

How to prevent

stress corrosion cracking? Stress corrosion cracking can be prevented through: How to prevent

stress corrosion cracking? Stress corrosion cracking can be prevented through:

|

|

|

For more details on Stress

Corrosion Cracking |

|

Where can I learn more about

stress corrosion cracking? More details on stress corrosion

cracking are included in the following

corrosion short courses which you can take as

in-house training courses,

course-on-demand, online

courses or distance

learning courses:

If you require corrosion expert witness or corrosion consulting service on stress corrosion cracking, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

|

Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2025.. All rights reserved. |