|

|

|

|

• EC • Season Cracking • Pitting • SSC • LME • MIC • SCC • HB-HE-HIC-HMx-HTHA • Fatigue • Erosion • Fretting • Stray Current • Index |

|

Different Types of

Corrosion

|

|

Hydrogen-Induced Cracking |

|

|

Recognition of Hydrogen-Induced Cracking (HIC) |

|

|

Hydrogen-Induced Cracking (HIC) is the stepwise internal cracks that connect adjacent hydrogen blisters on different planes in the metal, or to the metal surface. It is also known as stepwise cracking.

HIC is especially prevalent in iron alloys because of the restricted slip capabilities in the predominantly body-centered cubic (BCC) structure. HIC is generally limited to steels having a hardness of 22 or greater on the Rockwell C scale.

|

|

|

Mechanisms of Hydrogen-Induced Cracking (HIC) |

|

|

What causes hydrogen-induced cracking? Hydrogen-induced cracking results from atomic hydrogen being absorbed by solid metals. This can occur during elevated-temperature thermal treatments and in service during electroplating, contact with maintenance chemicals, wet H2S, corrosion reactions, cathodic protection, and operating in high-pressure hydrogen-containing environments.

|

|

|

Modeling, Prediction, and Prevention of Hydrogen-Induced Cracking (HIC) |

|

|

How to select alloy steels for resistance to

hydrogen-induced cracking?

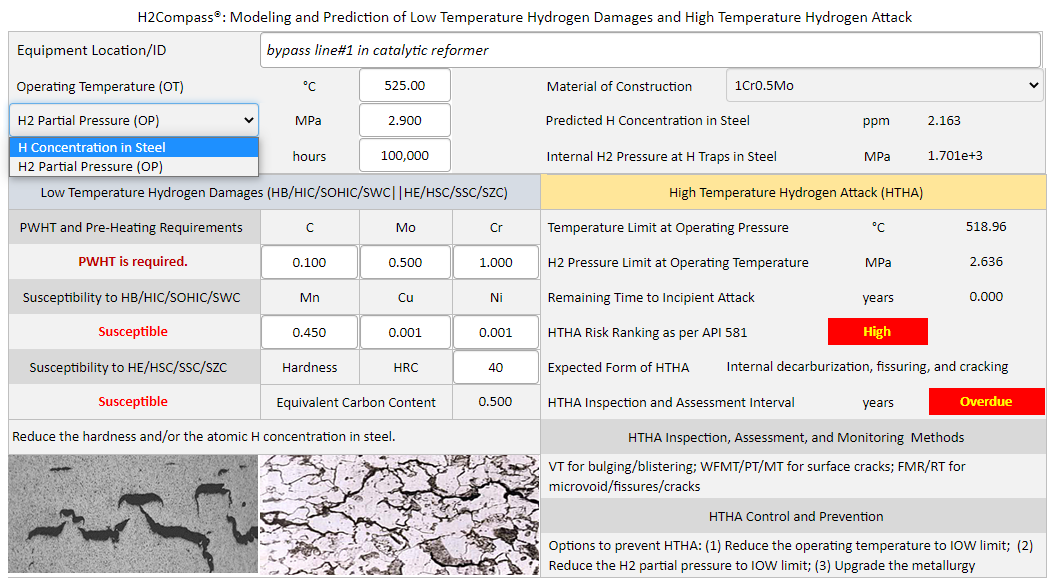

H2Compass is a powerful software for modeling and prediction of low temperature hydrogen damages and high temperature hydrogen attack (HTHA). H2Compass software provides instant answers to the above questions. The software can be used to determine the atomic hydrogen concentration in steels, the internal hydrogen gas pressure at hydrogen traps in steels, the steel's susceptibility to low temperature hydrogen damages, and the requirements for post-weld heat treatment (PWHT) and pre-heating.

How to prevent hydrogen-induced cracking? Hydrogen-induced cracking can be prevented through:

|

|

|

For more details on Hydrogen-Induced Cracking (HIC) |

|

|

Where can I learn more about hydrogen-induced cracking? More details on hydrogen-induced cracking are included in the following corrosion courses which you can take as in-house training courses, course-on-demand, online courses or distance learning courses:

If you require corrosion expert witness or corrosion consulting service on hydrogen induced cracking, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

|

Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2025.. All rights reserved. |