|

|

|

|

• Uniform • Galvanic • Crevice • Pitting • Intergranular • SSC • LME • MIC • SCC • HB-HE-HIC-MHx-HTHA • Fatigue • Stray Current • Index |

|

Different Types of

Corrosion

|

|

Hydride Embrittlement |

|

|

Recognition of Hydride Embrittlement |

|

|

What is hydride embrittlement? Hydride embrittlement refers to the cracking caused by the formation of brittle metal hydrides in some reactive metals such as magnesium, tantalum, niobium, vanadium, zirconium, titanium and their alloys in a hydrogen-containing environment. The phenomenon is sometimes called "hydride cracking".

|

|

|

Mechanisms of Hydride

Embrittlement |

|

|

The hydrogen may originate from welding work without adequate protection with regard to the environment, a heat treatment, corrosion processes or a casting operation without a controlled atmosphere.

Stresses in the metal accelerate the formation of hydride. Consequently, hydride formation will recur in the stress field at the crack tip, and the crack will continue to propagate until failure.

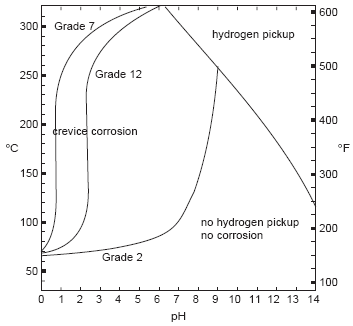

The graph shows the temperature-pH limits for some titanium alloys in NaCl brines.

|

|

|

Prevention of Hydride Embrittlement |

|

|

How to prevent hydride embrittlement? Hydride embrittlement can be prevented through:

|

|

|

For more details on Hydride

Embrittlement |

|

Where can I learn more about

hydride embrittlement? More details on

hydride embrittlement are included in the following

corrosion courses which you can take as

in-house training courses,

course-on-demand, online

courses or distance

learning courses:

If you require corrosion expert witness or corrosion consulting service on hydride embrittlement, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

|

Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2025.. All rights reserved. |