|

|

|

|

• EC • Caustic Embrittlement • Intergranular • SSC • LME • MIC • SCC • HB-HE-HIC-HMx-HTHA• Sulfidation • NAC • Erosion • Fretting • Stray Current • Index |

|

Different Types of

Corrosion

|

|

High-temperature Hydrogen Attack (Decarburization) |

|

|

|

|

|

High-temperature Hydrogen Attack (HTHA) refers to the loss of strength and ductility of steel by high-temperature reaction of absorbed hydrogen with carbides in the steel, resulting in decarburization and internal fissuring.

High-temperature hydrogen attack is also referred to as hot hydrogen attack or decarburization. It occurs in carbon and low-alloyed steels exposed for an extended period to hydrogen under high pressure and at high temperature.

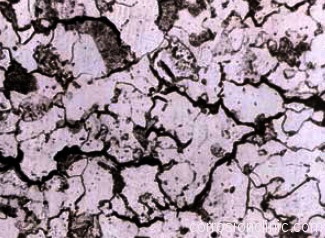

This micrograph shows intergranular cracking caused by high temperature hydrogen attack in a C-0.5Mo steel.

|

|

|

Mechanisms of High Temperature Hydrogen Attack |

|

|

What causes High-temperature hydrogen attack? Atomic hydrogen (formed in corrosion processes or by dissociation of molecular hydrogen in a gas stream at the steel surface) diffuses into steel. At grain boundaries, crystal imperfections, inclusions, discontinuities and other defects, the atomic hydrogen reacts with the dissolved carbon or with the metal carbides, forming methane: 8H+C+Fe3C =2CH4+3Fe (eq.1)

Because of the pressure build-up of the methane in the steel, this results in the formation of intergranular cracks (refer to the micrograph above), fissures and blisters, often extending to the surface of the steel. This form of hydrogen damage sometimes resembles the low-temperature hydrogen blistering. Moreover, the decarburization process leads to the loss of carbon in the steel and hence a reduction in tensile strength and an increase in ductility and creep rate. Interestingly, the reverse process (Eq.1 above), carburization, can also occur in hydrogen-hydrocarbon mixtures such as that encountered in petroleum-refining operations.

|

|

|

Modeling, Prediction and Prevention of High Temperature Hydrogen Attack |

|

|

How

to select alloy steels for high temperature hydrogen services?

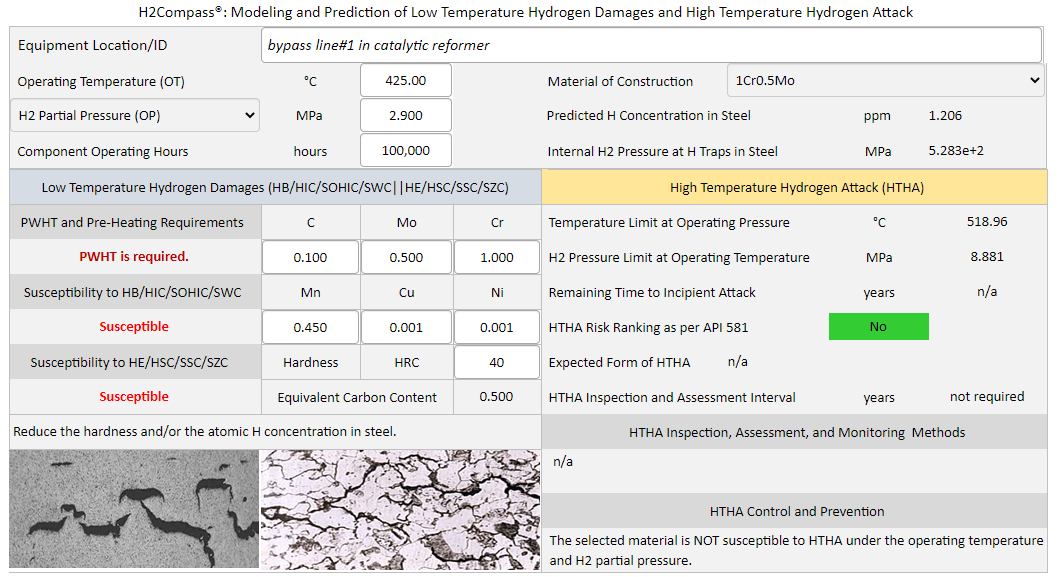

H2Compass is a powerful software for modeling and prediction of high temperature hydrogen attacks. H2Compass software provides instant answers to the above questions. The software can be used to determine the safe operating limits of temperature and hydrogen partial pressure for commonly used alloy steels in hydrogen services.

How to prevent High-temperature hydrogen attack? High-temperature hydrogen attack, decarburization and fissuring can be prevented through:

|

|

|

For more details on High Temperature Hydrogen Attack |

|

|

Where can I learn more about high temperature hydrogen attack? More details on high-temperature hydrogen attack are included in the following corrosion courses which you can take as in-house training courses, course-on-demand, online courses or distance learning courses:

If you require corrosion expert witness or corrosion consulting service on high temperature hydrogen attack, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

| Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2025.. All rights reserved. |

What is high-temperature hydrogen

attack?

What is high-temperature hydrogen

attack?