|

|

|

|

• EC • Season Cracking • Caustic Embrittlement • SCC • SSC • LME • HB-HE-HIC • MIC • Fatigue • Erosion • Fretting • Stray Current • Index |

|

Different Types of

Corrosion

|

|

Sulfide Stress Cracking (SSC) |

|

|

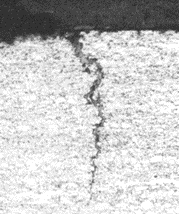

Recognition of Sulfide Stress Cracking |

|

|

What is Sulfide Stress Cracking (SSC)? Sulfide Stress Cracking is the cracking of a metal under the combined action of tensile stress and corrosion in the presence of water and hydrogen sulfide (a form of hydrogen stress cracking). Sulfide stress cracking is a form of hydrogen embrittlement that occurs in high-strength steels and in localized hard zones in weldment of susceptible materials when the environment contains wet H2S.

SSC is especially prevalent in iron alloys because of the restricted slip capabilities in the predominantly body-centered cubic (BCC) structure. SSC is generally limited to steels having a hardness of 22 or greater on the Rockwell C scale.

|

|

|

Mechanisms of Sulfide Stress Cracking |

|

|

What causes Sulfide Stress Cracking (SSC)?

There exist synergistic effects of high yield strength and high H2S concentration in the environment to cause SSC. SSC is frequently associated with welds. Atomic hydrogen diffuses into the steel and causes embrittlement of the very narrow hard zones in the heat-affected zones adjacent to welds. In regions of high tensile stress (residual or applied), crack will initiate, leading to crack propagation in a direction perpendicular to the tensile stress.

|

|

|

Prevention of Sulfide Stress Cracking |

|

|

How to prevent Sulfide Stress Cracking (SSC)? Sulfide Stress Cracking can be prevented through:

|

|

|

For more details on Sulfide Stress Cracking |

|

|

Where can I learn more about sulfide stress cracking? More details on Sulfide Stress Cracking (SSC) are included in the following corrosion courses which you can take as in-house training courses, course-on-demand, online courses or distance learning courses:

If you require corrosion expert witness or corrosion consulting service on sulfide stress corrosion cracking, our NACE certified Corrosion Specialist is able to help. Contact us for a quote. |

|

|

Home | Subject Index | Contact Us | PDF |

Copyright © 1995-2026.. All rights reserved. |