|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |||

Corrosion Testing and Corrosion Monitoring |

|||

|

|

|||

|

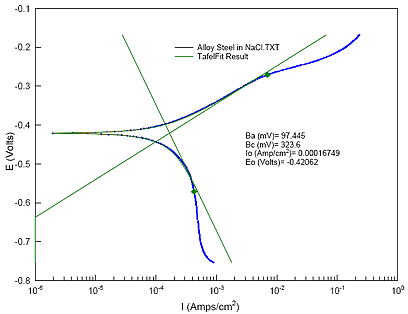

Verification or Certification Test: Verification of whether materials or products have been produced in accordance with the relevant international standards or to contract specifications may be established by corrosion test. WebCorr has access to a wide range of equipment and expert personnel for testing physical, mechanical and corrosion resistance properties of materials. DC and AC (EIS) Corrosion Testing & Monitoring techniques can be used for the following applications:

More application examples are given in the corrosion short course on "Corrosion Testing and Monitoring Made Easy: Techniques and Applications". |

|||

Typical Corrosion Testing and Monitoring Services Provided to Clients:

|

|||

| Short Courses Related to Corrosion Testing & Monitoring: | |||

|

The following corrosion short courses are relevant to corrosion testing and monitoring. They can be conducted at any time for you as in-house training courses, online courses or distance-learning courses.

Public courses, seminars and workshops are also conducted regularly. The contents and schedules of corrosion short courses for the current year is available here. |

|||

| Home | Back to Top | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |

||

WebCorr has

WebCorr has