|

It is always easier and cheaper to erase lines on a drawing than to

repair or replace failed components.

WebCorr has

NACE certified Corrosion Specialist providing

professional corrosion services including: corrosion design review, corrosion consulting, cathodic

protection design, in-house training, online and distance learning

corrosion courses, corrosion diagnosis,

failure analysis, corrosion expert witness in litigation and arbitration cases

related to corrosion, materials, metallurgy, paints & metallic coatings.

Our NACE certified Corrosion Specialist

can conduct a complete and detailed corrosion study and review of your

design to identify potential risks of corrosion between various

materials in the system and recommend mitigation measures including

alternative materials and effective protection methods.

WebCorr provides the following document preparation,

third party independent review and

endorsement services:

-

Development, independent review and

endorsement of

-

Corrosion Study,

-

Corrosion Design Basis Memorandum (CDBM),

-

Corrosion

Management Plan (CMP),

-

Corrosion Monitoring Plan and Philosophy,

-

Corrosion Control Manual, Corrosion Management Philosophy (CMP),

-

Corrosion Control Philosophy,

-

Material Selection Guide (MSG),

-

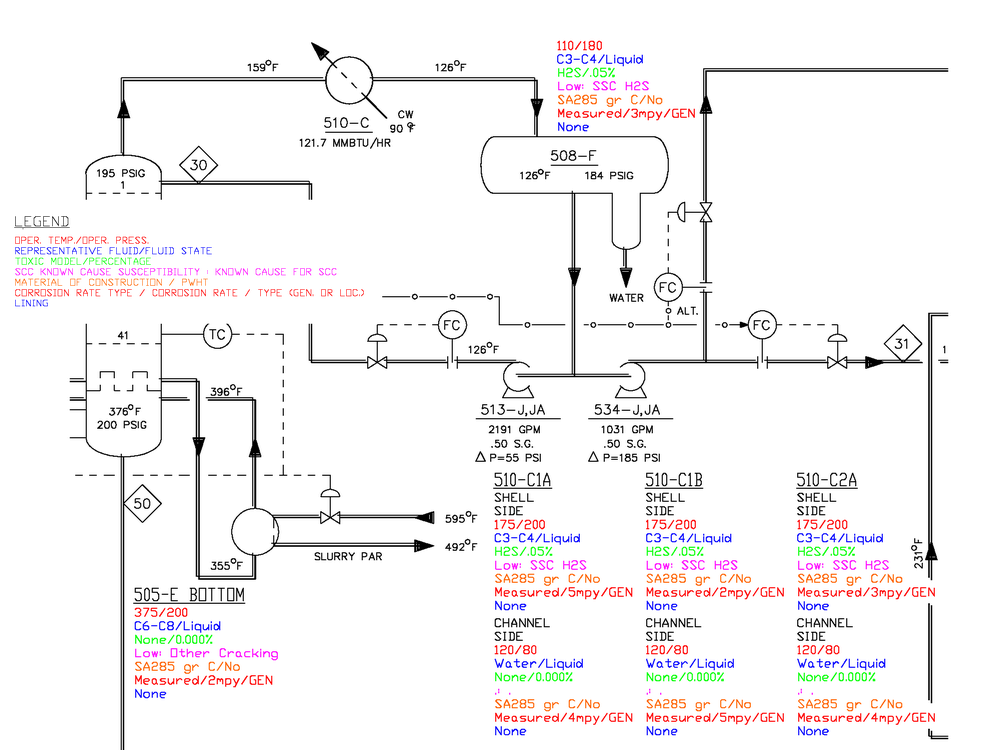

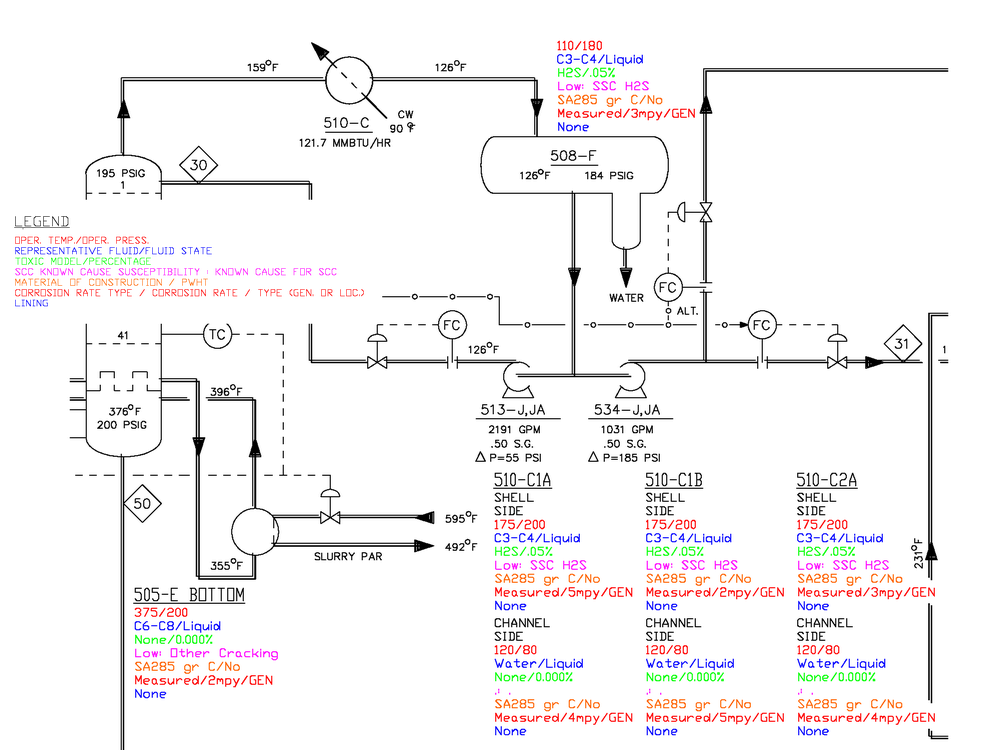

Material Selection Diagram (MSD),

-

Material Selection Summary Table (MSST).

-

Cathodic Protection Design.

-

Third-party review of designs, drawings and technical specifications to

identify potential corrosion risks, the compatibility of materials,

the forms of corrosion and their mitigation.

-

Third-party review

of design and specifications on materials, processes, cathodic

protection and coatings to

identify potential corrosion failures and any clauses in the

specification that may lead to potential dispute, arbitration or

litigation among the parties involved. Corrosion liability can be

avoided through proper specifications.

-

Independent 3rd party

verification/validation of modeled/predicted corrosion growth rates.

In CO2 corrosion modeling, there is no such thing that one model

fits all pipeline conditions. It is simply wrong for a

contractor/consultant to use one (1) modeling software for all

clients and all pipeline conditions. At WebCorr, our NACE certified

Corrosion Specialist will validate your modeled/predicted corrosion

growth rates using properly selected models, laboratory test results

and field data in the literature. Our verification/validation report

will come complete with all supporting data and reference documents.

If necessary, we can train your engineers on CO2 modeling. Click the link below to see details on our 5-day training course on CO2

modeling:

CO2 Corrosion Modeling for the Prediction of Internal Corrosion in

Oil Gas Pipelines

-

Third-party review of contracts to identify potential corrosion liabilities

and advices on how to deal with them

-

Third party

review of test reports and interpretations of test results

-

Technical bid evaluation support

-

Analysis of raw data from corrosion tests (both DC polarizations &

AC EIS

impedance measurements) and interpretation of corrosion test results

-

Expert witness and support in litigation and arbitration

matters related to corrosion, materials, metallurgy, paints & metallic coatings including thermal spray metallizing, galvanizing,

anodizing, chromating, phosphating, electroplating, electroless

plating, mechanical plating, and sheradizing or diffusion coating.

Back to Top

Go to Examples

Service Quality Guarantee

- Why You Need Your Corrosion Consultant to Have NACE Certification

NACE Certified Corrosion Specialist

- The highest level of certification; your

guarantee of the highest quality of services.

What does it take to

become a NACE certified Corrosion Specialist?

NACE stands for National Association of Corrosion Engineers

(USA). It is the largest corrosion professional institution in the world.

With reference to Corrosion Specialist certification,

NACE certification document states:

"Our highest level of corrosion certification, the Corrosion Specialist certification is geared towards very experienced corrosion control personnel, with broad and extensive expertise, in both the theory and practice of multiple areas of corrosion and corrosion control, and capable of performing work at a very advanced level."

The hierarchy structure of NACE certification is shown below (click

on each title to see the detailed requirements):

The highest level of certification by the

world's largest corrosion professional institution is your best

guarantee of the highest quality of services you can expect from WebCorr Corrosion

Consulting Services. Corrosion consultants with NACE certification at the

Corrosion Specialist level can save you a lot of money and make your

life a lot easier.

Read this story on the mis-diagnosis of Stray Current Corrosion.

Back to Top

Go to Examples |

Subject: Design Consultancy Enquiry

Date: Wed, 8 Sep 2004 18:09:06 +0200

Dear Sirs,

we are interested in contracting your services for an independent design

consultancy review for two industrial shell and tube heat exchangers (AET

type). These shell and tube heat exchangers are being supplied by our

Company, [name removed] (Engineering

Contractor Company), and the final Client is [company

name removed].

In order to give you a brief idea, the materials in question are:

- Tubesheets: Carbon Steel titanium cladded from the tube side process

and bundle cage in SS 316 L ( SS 316 L baffles, tie rods ,spacers,

sealing strips and bundle runners instead of carbon steel ).

- Tubes: Ti

- Baffle plates: SS316 L

- Process shell side fluid: Hydrogen (Wet Sour/HIC Service)

- Tube side fluid: Sea Water

- Shell Material: KCS HIC Resistant (Full details such as datasheets,

specifications and drawings will be provided later).

The consultancy would consist of a design review of this equipment with

particular regard to material choice for tubes, baffles and tubesheets

with respect to the possibility of galvanic corrosion and/or hydrogen

embrittlement cracking between tubes, baffles and tubesheet materials

owing to the design conditions and process fluids. We would appreciate

it if you could provide us with a quotation and/or indicate your

standard rates for this type of consultancy including the delivery date

for your final technical report.

We look forward to hearing from you.

Best Regards,

[name removed] Project Engineer [company

name removed], Heat Transfer Division

Madrid (Spain)

Back to Top

Back to Examples

|