|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | ||

|

An Advanced Course

in Cathodic Protection |

||

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List | Why WebCorr |

||

|

Course Overview |

||

|

This corrosion short course can be taken as in-house training course, online course and distance learning course worldwide. It can also be customized to meet the specific needs of your organization.

|

||

|

||

|

1. Primer on Chemistry, Metallurgy, Electricity and Mathematics 1.1 Basic Concepts in Chemistry Relevant to Corrosion and Cathodic Protection 1.2 Basic Concepts in Metallurgy Relevant to Corrosion and Cathodic Protection 1.3 Basic Concepts in Electricity Relevant to Corrosion and Cathodic Protection 1.4 Basic Math Requirement in Cathodic Protection Design Calculations 1.5 Exercises and Quiz

2. Fundamentals of Corrosion 2.1 Why do metals corrode 2.2 How do metals corrode 2.3 General methods of corrosion control and prevention 2.4 Exercises and Quiz

3. Corrosion and Cathodic Protection 3.1 History of Cathodic Protection 3.2 How it works 3.3 Why it works 3.4 How effective it is 3.5 Exercises and Quiz

4. Practical Parameters in Cathodic Protection 4.1 Structure potentials 4.2 CP Protection Criteria: which one to use ? 4.3 Is 100 mV polarization enough? -Optimization of cathodic protection design 4.4 Current density requirements 4.5 Coatings and Cathodic Protection 4.6 Exercises and Quiz

5. Resistivity and Electrode Resistance 5.1 Electrical resistivity 5.2 Resistance of ground connections 5.3 Non-uniform electrolytes 5.4 Groundbed design 5.5 Long pipeline and pipe insulating joints 5.6 Exercises and Quiz

6. Sacrificial Anode Cathodic Protection

6.1 Methods of Applying

Cathodic Protection 6.8 Specifications of Galvanic Anode Systems 6.9 Anode Installation 6.10 Exercises and Quiz

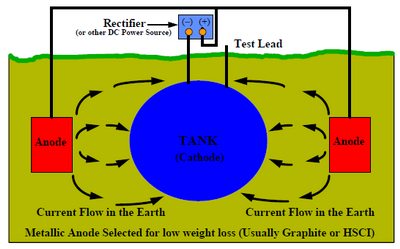

7. Impressed Current Cathodic Protection

7.1 Impressed Current Systems 7.10 Exercises and Quiz

8. Cathodic Protection Standards, Specification and Design 8.1 Applicable International Standards on Cathodic Protection 8.2 Cathodic Protection Specification 8.3 Cathodic Protection Design Fundamentals 8.4 Determining Current Requirements 8.5 Calculating Cathodic Protection Circuit Resistance 8.6 Calculating System Capacity and Life 8.7 Cathodic Protection Design Procedure 8.7.1 The 10-Step Guide to the Design of Galvanic Anode Cathodic Protection System 8.7.2 The 10-Step Guide to the Design of Impressed Current Cathodic Protection System 8.8 Design of Cathodic Protection Monitoring Facilities 8.8.1 Current Distribution 8.8.2 Attenuation 8.9 Computer software for cathodic protection design, modeling and corrosion prediction: CP-Compass 8.10 Exercises and Quiz

9. Cathodic Protection of Underground Pipelines and Storage Tanks 9.1 Understanding ISO 15589-1 Petroleum and natural gas industries - Cathodic protection of pipeline transportation systems - On-land pipelines 9.2 Understanding NACE SP0169 Control of External Corrosion on Underground or Submerged Metallic Piping Systems 9.3 Cathodic Protection of Underground Pipelines 9.4 Cathodic Protection of Storage Tanks 9.5 Design Examples and Exercises 9.6 Exercises and Quiz

10. Cathodic Protection of Marine and Offshore Structures 10.1 The nature of sea water and its impact on corrosion of steel structures 10.2 Understanding DNV-RP-B401 Cathodic Protection Design 10.3 Understanding DNV-RP-F103 Cathodic Protection of Submarine Pipelines by Galvanic Anodes 10.4 Understanding ISO 15589-2 Petroleum and natural gas industries - Cathodic protection of pipeline transportation systems - Offshore pipelines 10.5 Understanding BS EN 12474 Cathodic protection of submarine pipelines 10.6 Understanding NORSOK M-503 Cathodic protection 10.7 Understanding NACE SP0176 Corrosion Control of Submerged Areas of Permanently Installed Steel Offshore Structures Associated with Petroleum Production 10.8 Slope Parameter Method in Cathodic Protection Design 10.9 Exercises and Quiz

11. Cathodic Protection of Concrete Structures 11.1 The nature of concrete structure

11.2

Understanding AS 2832-5 Cathodic protection of metals - Part 5: Steel in concrete structures 11.6 Innovative Cathodic Protection systems for various concrete structures 11.7 Sacrificial anode cathodic protection systems 11.8 Anodes selection for impressed current Cathodic Protection systems 11.9 Effectiveness of Cathodic Protection in concrete structures 11.10 Optimization of Cathodic Protection systems for concrete structures 11.11 Design Exercises and Quiz

12. Stray Current and Cathodic Protection Interference, and Methods of Prevention 12.1 Stray current corrosion and electrolysis 12.2 Practical stray current problems and solutions 12.3 Interference from other Cathodic Protection installations 12.4 AC Testing and Mitigation 12.5 Exercises and Quiz

13. Cathodic Protection Commissioning, Inspection and Monitoring 13.1 Equipment tests 13.2 System tests 13.3 Inspection and monitoring 13.4 Frequency of routine inspection 13.5 Monitoring plan 13.6 Monitoring equipment 13.7 Specialized surveys 13.8 Maintenance and repair 13.9 Exercises and Quiz

14. Cathodic Protection and Coatings 14.1 Economic considerations 14.2 Specification 14.3 Inspection 14.4 Type of coatings 14.5 Coating failures and analysis 14.6 Exercises and Quiz

15. Pipeline Inspection: Survey Methods and Evaluation Techniques 15.1 Survey methods for pipeline not under cathodic protection 15.2 Survey methods for pipeline under cathodic protection 15.3 NACE Standard on “Pipeline External Corrosion Direct Assessment Methodology” 15.4 Modeling and Prediction of External Corrosion of Underground Pipelines 15.5 Modeling and Prediction of Pipeline Internal Corrosion 15.6 Exercises and Quiz

16. Overall Discussion, Questions and Answers, Course Feedback

17. Examination 17.1 General Knowledge on Corrosion and Cathodic Protection 17.2 Cathodic Protection Specification, Design, Commissioning, Testing and Monitoring

|

||

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List |

||

Successful completion of this corrosion course helps participants prepare for their NACE certification examinations at the Corrosion Technician, Corrosion Technologist and Senior Corrosion Technologist levels. |

||

| Registration for This Corrosion Course | ||

|

Click here to register for this corrosion course online, or Click here to download this corrosion course brochure with registration form in PDF format.

|

||

| In-House Training Corrosion Courses | ||

|

There is no limit to the number of participants required for in-house training corrosion courses. We conduct the in-house training corrosion course at your company's premises worldwide, and at a time convenient to your company.

Click here to contact us for a quotation for in-house training corrosion courses. |

||

| Online and Distance Learning Corrosion Courses | ||

|

Click here to to register an online corrosion short course. |

||

| Corrosion Course-On-Demand | ||

|

Click here to contact us for a quotation. |

||

| Corrosion Course-On-Webex | ||

|

Click here to contact us for a quotation. |

||

| PowerPoint Slides and Test Banks for Trainers, Instructors, Tutors, University Lecturers and Professors | ||

|

If you are involved in teaching or training, you may wish to purchase a complete set of the trainer's package for this training course. The trainer's package comes complete with ready-to-use PowerPoint slides (fully editable) and test bank (with answer keys). These ready-to-use PowerPoint slides contain high quality color photographs, illustrations, animations, audio and video clips. The test bank contains questions conveniently grouped into four categories: (1) true or false, (2) multiple choice, (3) calculation, and (4) reasoning and open-ended discussions. The trainer's package is suitable for in-house training and university teaching (30 lecture hours). This is exactly the same package that WebCorr uses to deliver our current training course. The one-time lump sum fee allows your organization to use the training package and also modify it. For example, your organization may modify the course contents and re-name/re-brand the course under your organization’s name. WebCorr only retains the copyright of the original PowerPoint slides and test banks.

Click here to contact us if you need more information on the trainer's package. |

||

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List |

||

|

Copyright © 1995-2024. All rights reserved. |

||

Cathodic

protection is a mature technique for controlling corrosion of steel

structures immersed in waters, buried in soils and imbedded in concrete.

This 5-day advanced course thoroughly and systematically

covers the fundamental principles of cathodic protection and its

practical applications such as marine and offshore structures in

seawater environment, storage tanks and pipelines buried in soils, and

reinforcing steels embedded in concrete structures. The course will provide

detailed information on cathodic protection specification, design, commissioning, testing

and monitoring. Applicable standards such as NACE, BS/ISO, AS and DnV

relevant to cathodic protection design will be discussed. State-of-the-art anode

materials for cathodic protection will be presented. Participants will

gain advanced knowledge and skills in cathodic protection of common

types of steel structures immersed in waters, buried in soils and imbedded in

concrete. Included in the course notes are the 10-Step Guides to the

design of galvanic anode cathodic protection system and impressed

current cathodic protection system. Hands-on practical sections provide opportunities for participants to

operate the devices and instruments used in cathodic protection.

Engineers, architects and designers will grasp the theories and

practices of cathodic protection which would lead to corrosion-proof

designs and low cost durability. Participants will learn the principles

and applications of advanced sensors and monitoring systems for cathodic

protection

monitoring, condition survey, diagnosis and troubleshooting. Facility

owners will benefit from the enhanced safety and reduced maintenance

costs.

Cathodic

protection is a mature technique for controlling corrosion of steel

structures immersed in waters, buried in soils and imbedded in concrete.

This 5-day advanced course thoroughly and systematically

covers the fundamental principles of cathodic protection and its

practical applications such as marine and offshore structures in

seawater environment, storage tanks and pipelines buried in soils, and

reinforcing steels embedded in concrete structures. The course will provide

detailed information on cathodic protection specification, design, commissioning, testing

and monitoring. Applicable standards such as NACE, BS/ISO, AS and DnV

relevant to cathodic protection design will be discussed. State-of-the-art anode

materials for cathodic protection will be presented. Participants will

gain advanced knowledge and skills in cathodic protection of common

types of steel structures immersed in waters, buried in soils and imbedded in

concrete. Included in the course notes are the 10-Step Guides to the

design of galvanic anode cathodic protection system and impressed

current cathodic protection system. Hands-on practical sections provide opportunities for participants to

operate the devices and instruments used in cathodic protection.

Engineers, architects and designers will grasp the theories and

practices of cathodic protection which would lead to corrosion-proof

designs and low cost durability. Participants will learn the principles

and applications of advanced sensors and monitoring systems for cathodic

protection

monitoring, condition survey, diagnosis and troubleshooting. Facility

owners will benefit from the enhanced safety and reduced maintenance

costs. If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning. All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.