|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |||||||||||||||||||

Shipwreck-Compass®: Software for Shipwreck Corrosion Modeling and Shipwreck Corrosion Prediction Version 9.21

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|||||||||||||||||||

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|||||||||||||||||||

|

Features and Functions of Shipwreck-Compass |

|||||||||||||||||||

|

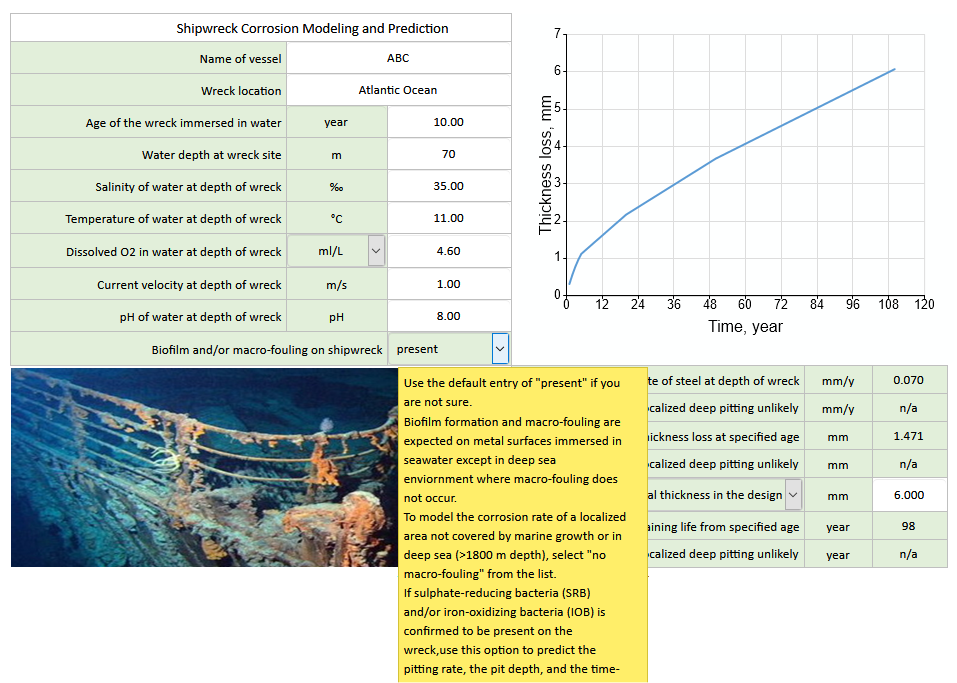

Shipwreck-Compass is the only device and OS independent software tool on the market for shipwreck corrosion modeling and corrosion prediction. Its predictive engine is based on the rigorous frameworks of thermodynamics, physical chemistry, and corrosion kinetics. This software tool models the effects of dissolved oxygen, temperature, salinity, current velocity, pH, depth of water, marine growth and microorganisms including sulphate-reducing bacteria (SRB) and iron-oxidizing bacteria (IOB) on the corrosion rate, pitting rate, the thickness loss, pit depth, the remaining life, and the time-to-perforation, as shown in Figure 1 below for an oil tanker sank in the Atlantic Ocean in 2002.

Figure 1 Shipwreck-Compass Predicts Shipwreck the Corrosion Rate, the Thickness Loss, and the Remaining Life.

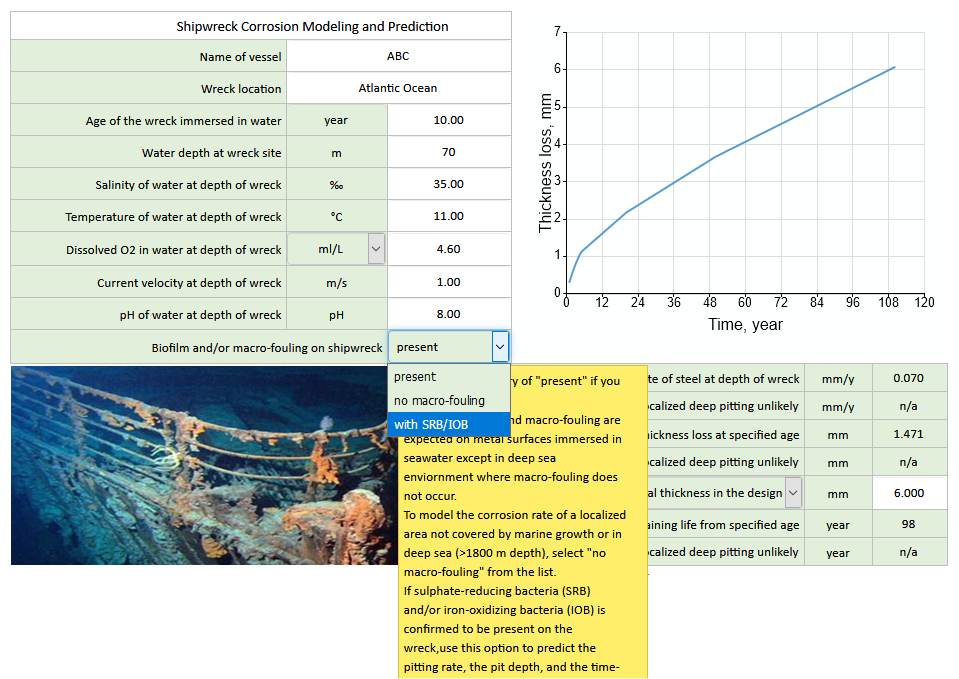

The predictive engine in Shipwreck-Compass also takes into account the effects of marine growth and microorganisms that are present in seawater environments (Figures 2a and 2b). The biofilms that form on the metal surface have the capability to influence the corrosion of the metal. The film itself can range from a microbiological slime film to a heavy encrustation of hard-shelled fouling organisms. This influence of biofilm derives from the ability of the organisms to change the local environmental variables important to corrosion such as dissolved oxygen, temperature, velocity, pH and others. For example, a heavy encrustation of bio-fouling organisms on steel immersed in seawater will often decrease the corrosion rate of the steel as long as the cover of organisms remains complete and relatively uniform. The heavy fouling layer acts as a barrier film in limiting the amount of dissolved oxygen reaching the metal surface, thus reducing the thickness loss of the steel. A layer of hard-shelled organisms, such as barnacles or mussels, on steel also shields the metal from the damaging effect of wave action.

Figure 2a: Modeling the effect of marine growth and microorganisms on

corrosion.

Figure 2b: Modeling the effect of marine growth and microorganisms on corrosion.

Shipwreck-Compass was designed with end users in mind. Experience the first cross-platform and device-independent Shipwreck Corrosion Modeling and Prediction application on your iPads, tablets, smart phones, notebooks and desktops, at any time and anywhere, in the office or on the sea. No installation files to download, no browser plug-ins required, no USB dongles to carry around, and no license keys to transfer from one PC to another. Shipwreck-Compass simply works on any device running any OS. All you need is an internet browser.

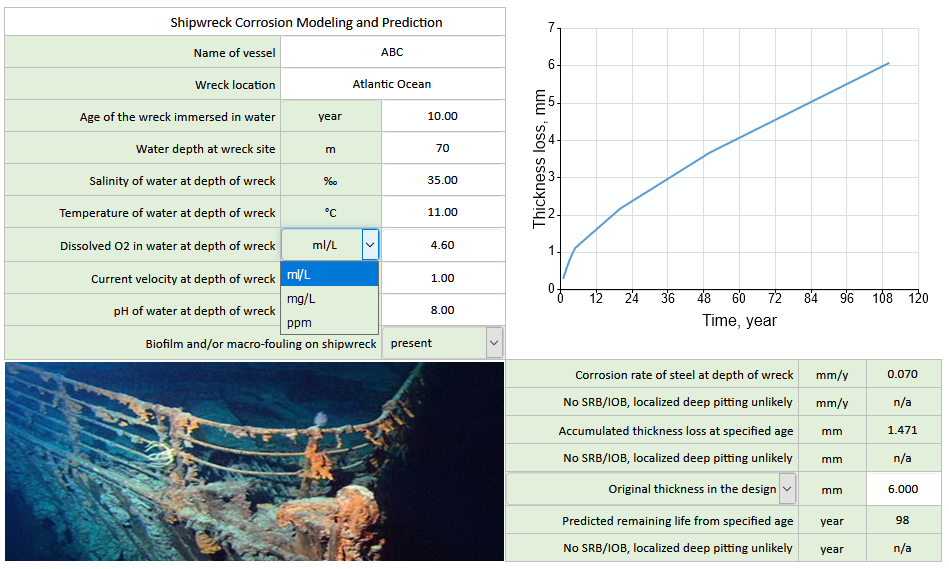

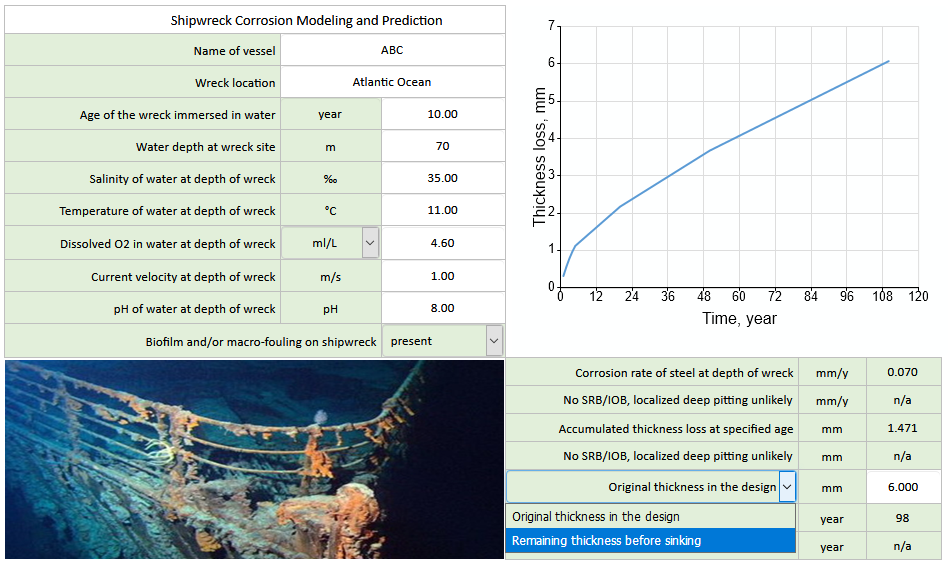

Users can enter the dissolved oxygen concentration in any unit without the need to do manual conversion (Figure 3). To predict the remaining life, users can either enter the original thickness in the design (if known) or the remaining thickness (if measured), as shown in Figure 4.

Figure 3 Dissolved Oxygen Concentration and Shipwreck Corrosion Prediction

Figure 4 Remaining Life Prediction of Shipwreck

Corrosion Prediction of a Warship Sank in World War I in 1915 In this application example, we have a look at the Corrosion Prediction of Submarine HMAS AE2 (1915) in the Sea of Marmara, Turkey. The Australian submarine AE2 was built in 1912 by Vickers Armstrong at Barrow-in-Furness, England, launched in 1913 and sank on 25 April 1915 at a depth of 73 m at the bottom of the Sea of Marmara, Turkey during World War I. The seawater physicochemical properties are as follows: Temperature: 14.1°C Dissolved oxygen: 2.6 ppm Salinity: 41.3 The ballast tank with an original thickness of 6.35 mm lost 1.75 mm in 92.4 years (till 2007) based on ultrasonic thickness gauge measurement, giving a corrosion rate of 0.0189 mm/y. Figure 5 shows the prediction results from Shipwreck-Compass.Table 1 compares the measured and the predicted thickness loss and the corrosion rate. Shipwreck-Compass predicts that the remaining life of the ballast tank is 253 years.

Figure 5 Shipwreck-Compass Prediction of shipwreck corrosion and remaining life forSubmarine HMAS AE2 (1915) Table 1 Comparison of the measured and the predicted thickness loss and the corrosion rate.

Corrosion Prediction of the USS Monitor Sank in 1862 The USS Monitor was the first iron-clad battleship equipped with a revolving gun turret constructed from 8 layers of 1-inch (2.54 cm) iron plates. It sank in a storm in December 1862 off the coast of Cape Hatteras, North Carolina, at a water depth of 70 m.

Ultrasonic thickness measurements conducted in 2007 (144 years after sinking) on the outer turret plates at eight locations near the gun openings showed a thickness loss of about 5 mm. This gives an average measured corrosion rate of 0.035 mm/y.Figure 6 shows the prediction results from Shipwreck-Compass. The predicted corrosion rate is 0.037 mm/y and the predicted thickness loss is 5.4 mm.

Figure 6 Shipwreck-Compass Prediction of shipwreck corrosion and remaining life for the USS Monitor (1862)

Table 2 Comparison of the measured and the predicted thickness loss and the corrosion rate. Measured using ultrasonic thickness gauge Predicted using Shipwreck-Compass 5 mm 5.4 mm 0.035 mm/y 0.037 mm/y

Modeling the Remaining Life of the Sea Diamond Wreckage M/S Cruiser Sea Diamond (formerly known as Bikra Princess) sank on April 6th, 2007 a few hundred meters away from the commercial harbour of Athenio in Santorini, Thera island. Shipwreck-Compass (previously known as CO2Compass-SE, Shipwreck Edition) was used to model the effects of seawater physicochemical parameters on the remaining life of the superstructure and hull plates. Detailed modeling results were published in the the Open Journal of Ecology, 2020, 10, 537-570 (click the title to download the full paper):

The powerful applications of Shipwreck-Compass are truly unlimited in both the conservation of shipwrecks with cultural and historic values and the risk assessment of shipwrecks with environmental concerns.

|

|||||||||||||||||||

Shipwreck-Compass, giving you the right directions in Shipwreck Corrosion Modeling and Corrosion Prediction |

|||||||||||||||||||

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |

||||||||||||||||||

There are many shipwrecks at the bottoms of oceans around the world. Statistics shows that in the Pacific Ocean alone, there are about 3,000 WWII shipwrecks at risk of leaking oil and around 10 per cent of the wrecks are oil tankers. Some of these wreckages have cultural and historic significance while others have serious environmental concerns such as oil leaking due to corrosion of the hull plate. Accurate prediction of the corrosion rate and hence the remaining life, or the time-to-perforation is important both to the conservation of historic shipwrecks and to the environmental risk assessment of others.

There are many shipwrecks at the bottoms of oceans around the world. Statistics shows that in the Pacific Ocean alone, there are about 3,000 WWII shipwrecks at risk of leaking oil and around 10 per cent of the wrecks are oil tankers. Some of these wreckages have cultural and historic significance while others have serious environmental concerns such as oil leaking due to corrosion of the hull plate. Accurate prediction of the corrosion rate and hence the remaining life, or the time-to-perforation is important both to the conservation of historic shipwrecks and to the environmental risk assessment of others.