|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series Concrete-Compass®: Corrosion Modeling and Life Prediction of Reinforced Concrete Structures The Ultimate Software Solutions to Costly Concrete Corrosion Version 9.23

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview of Concrete-Compass Software for Concrete Corrosion Modeling and Life Prediction |

|

|

The outputs of Concrete-Compass include the following:

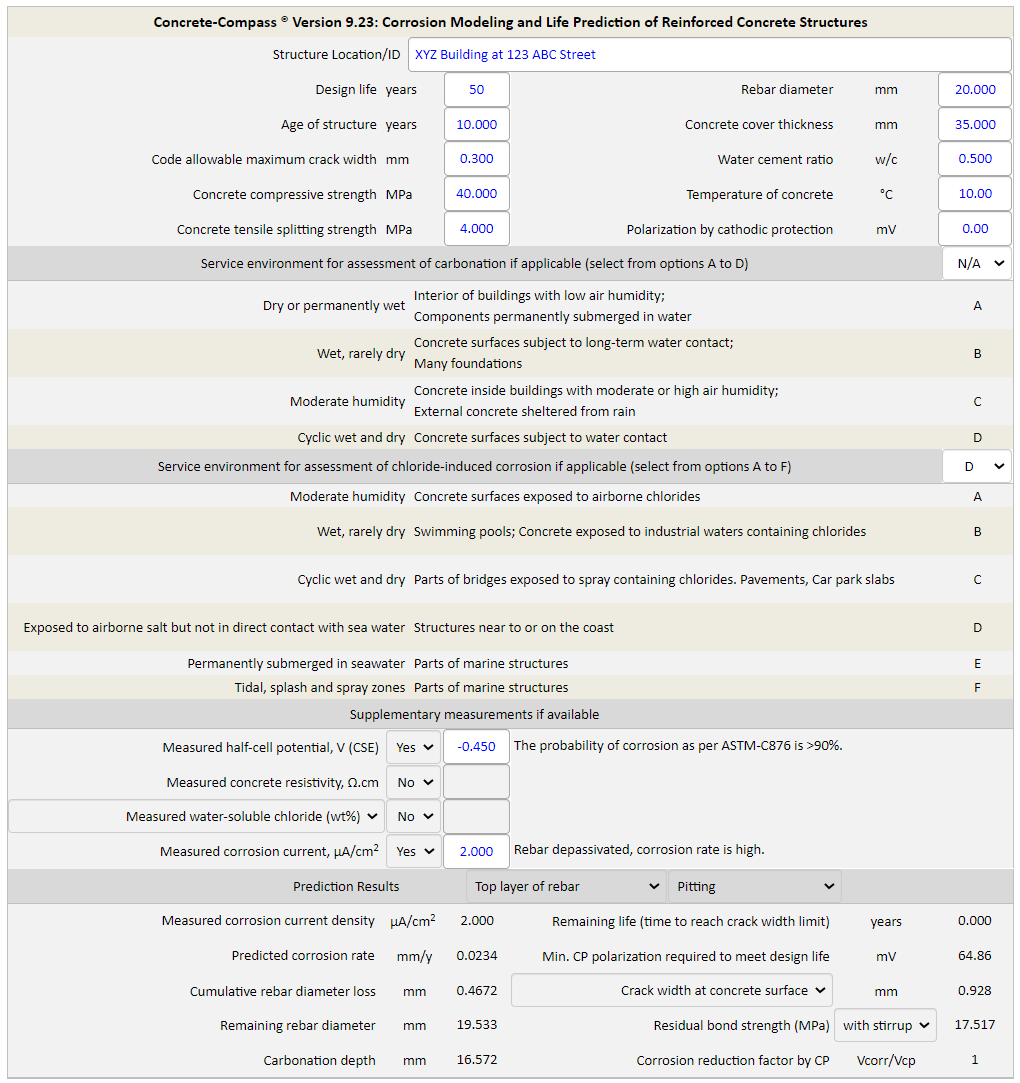

Figures below show the screen shots of Concrete-Compass.

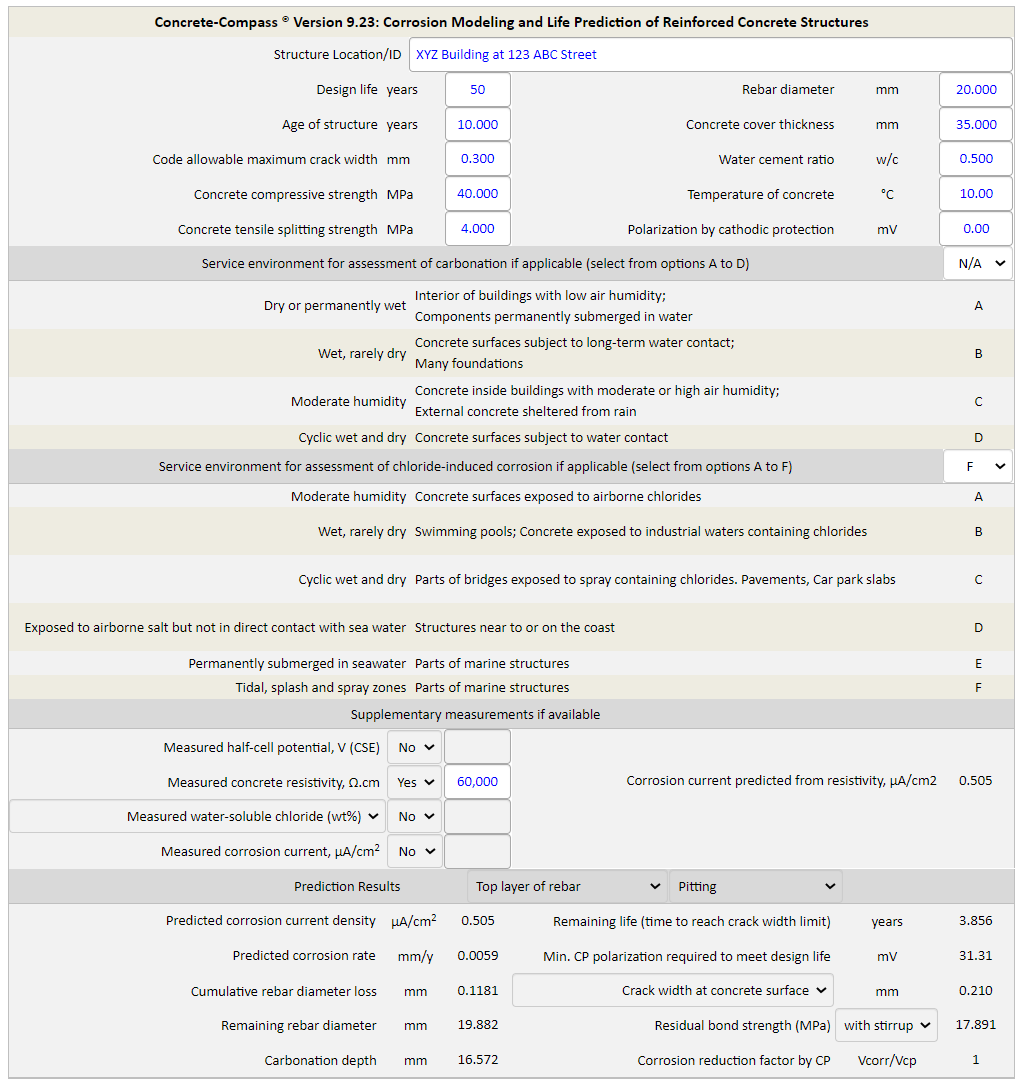

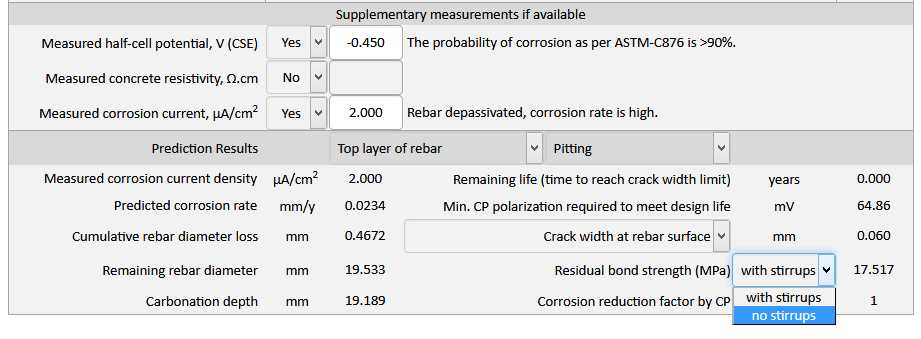

Figure 1 Concrete-Compass Predicts the rate of Concrete corrosion and the remaining life of RC structures.

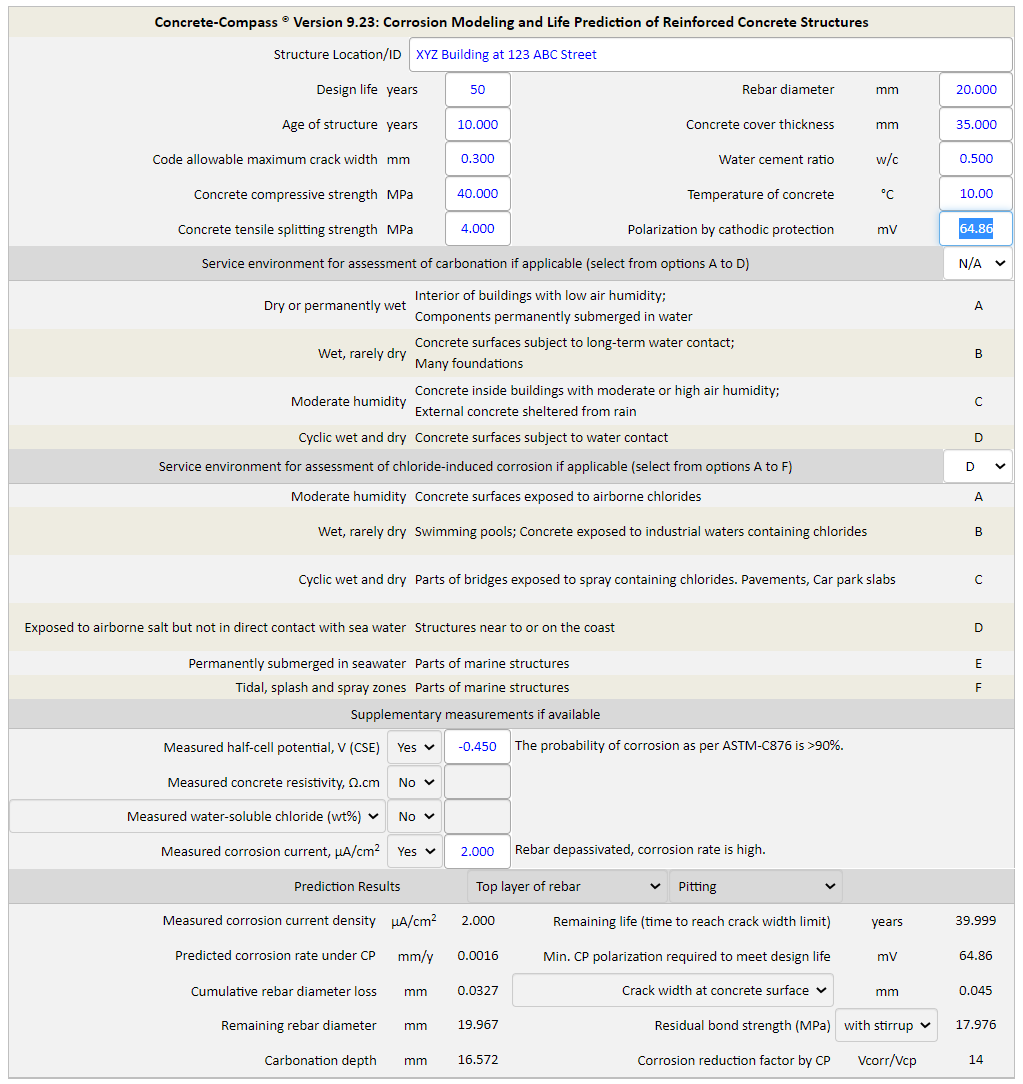

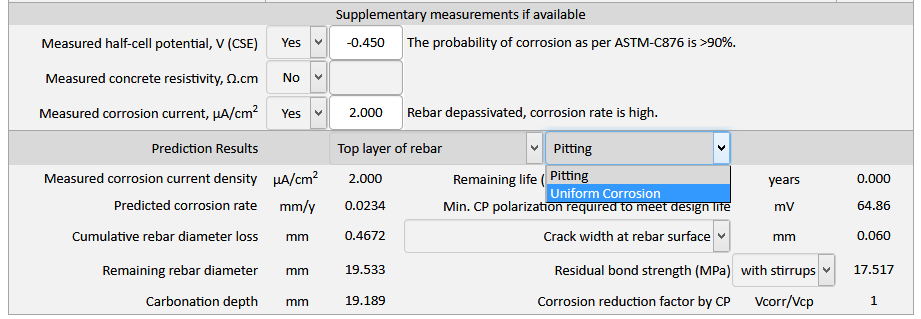

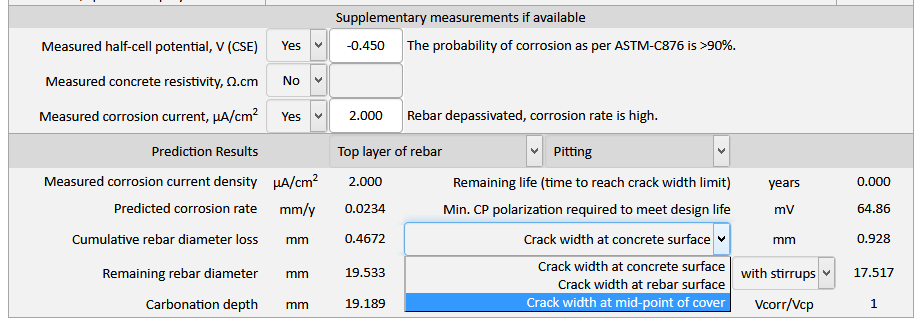

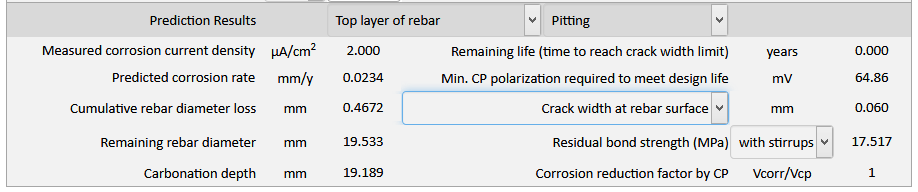

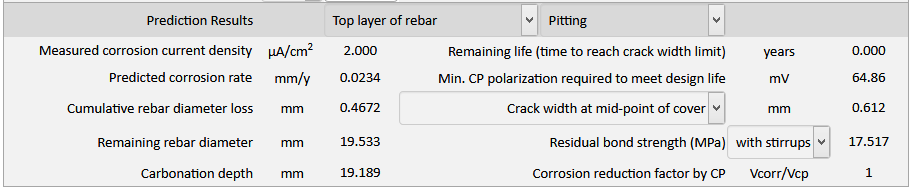

Under the specified conditions shown in Figure 1 above, Concrete-Compass predicts that the design life of 50 years with a crack width limit of 0.300 mm is not met. The crack opening at the concrete surface is 0.928 mm, the residual bond strength with (stirrups) is 17.517, and the carbonation depth is 19.189 mm. The minimum CP polarization required to reduce the corrosion rate to a level that can meet the design life (crack width limit of 0.300 mm) is 64.86 mV. In Figure 2, with cathodic protection polarization of 64.86 mV, Concrete-Compass predicts the remaining life is 40 years, thus meeting the design life of 50 years (age 10 + 40). Figure 3 shows that at age 50, the predicted crack width is 0.304 mm, meeting the design limit of 0.3 mm.

The predictive engine used in Concrete-Compass for corrosion modeling and life prediction of reinforced concrete structures complies with applicable international standards and relevant industry best practices.

Using Concrete-Compass is as easy as 1-2-3. (1) Enter the design data. (2) Select the service environment. (3) Review the prediction results. The following figures show the screen shots of Concrete-Compass.

Figure 2 Concrete-Compass predicts concrete corrosion, crack width, bond strength, and cathodic protection requirement.

Figure 3 Concrete-Compass predicts concrete corrosion and effectiveness of cathodic protection.

When corrosion current density is measured, Concrete-Compass models the effects of corrosion current density and the service environment on the crack width and the remaining life of the RC structures. If the corrosion current density of reinforcing steel is not measured but concrete resistivity data is available, Concrete-Compass models the effects of concrete resistivity and the service environment on the risks of concrete corrosion and predicts the crack width and the remaining life of the RC structures (Figure 4).

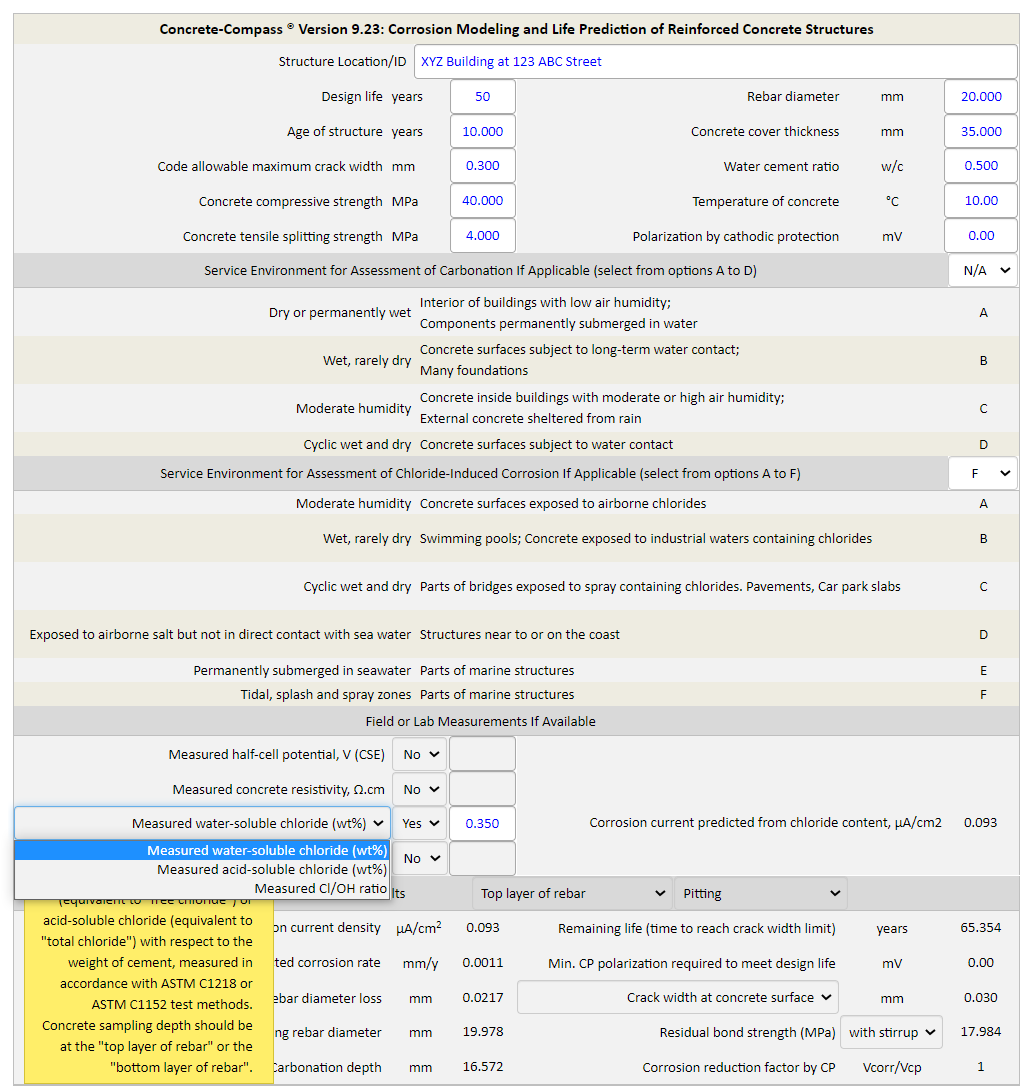

Figure 5 shows that Concrete-Compass models the effects of chloride

content in concrete, measured as the total chloride (acid-soluble

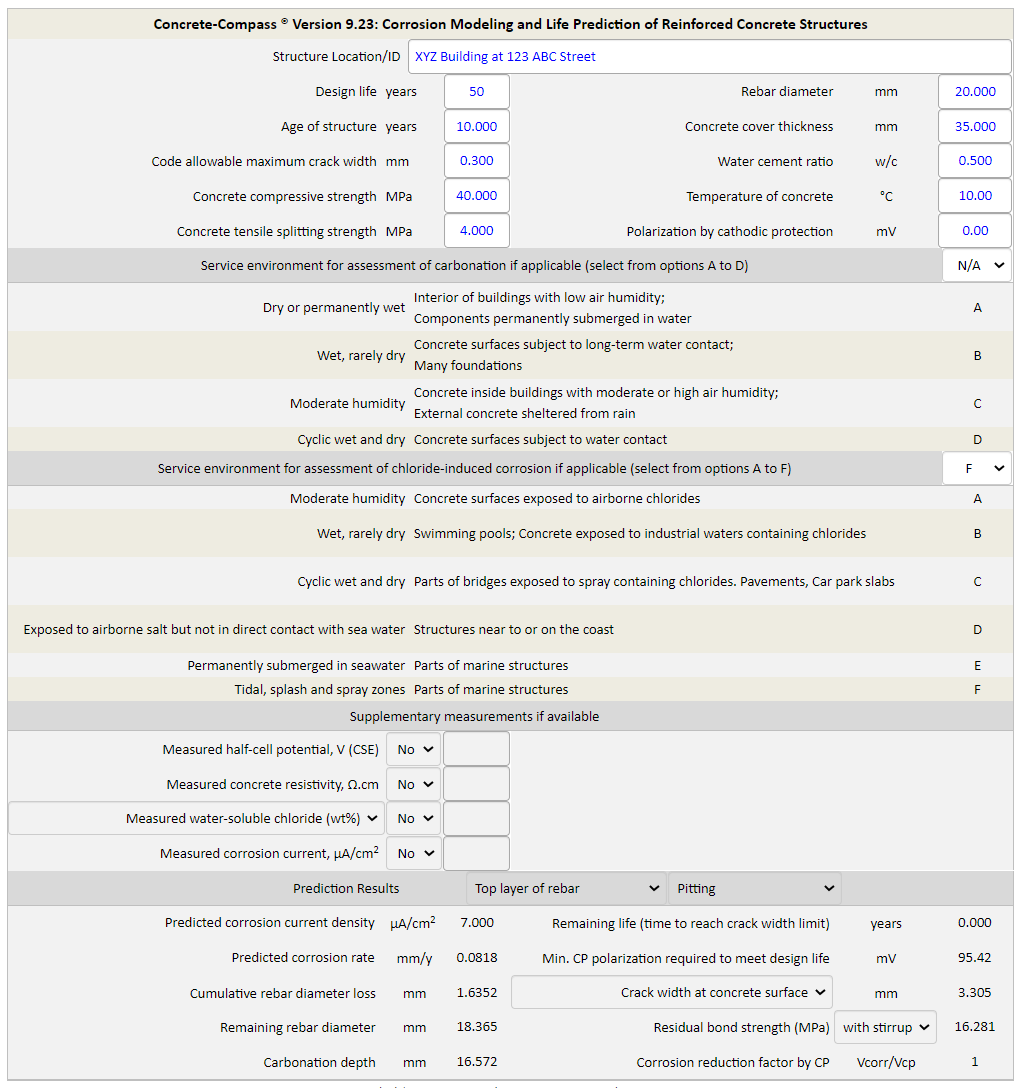

chloride) or free chloride (water-soluble chloride). If no measurement data are available, Concrete-Compass models the effect of the service environment in accordance with BS EN 206 and predicts the crack width and remaining life of the RC structures (Figure 6).

Figure 4 Concrete-Compass predicts concrete corrosion, crack width and remaining life from concrete resistivity data.

Figure 5 Concrete-Compass models the effects of total chloride (acid-soluble chloride), free chloride (water-soluble chloride),

and Cl/OH ratio on the corrosion rate.

Figure 6 Concrete-Compass predicts concrete corrosion, crack width and remaining life of RC structures in accordance with BS EN 206 concrete exposure class.

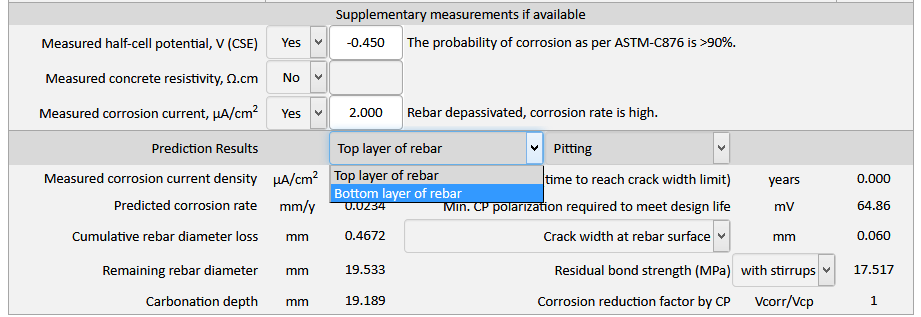

Concrete-Compass models and predicts the effects of rebar position (top layer vs. bottom layer) and types of corrosion (pitting vs. uniform corrosion) on the crack width and remaining life of RC structures (Figures

9 & 10). The crack width at different depth of over from concrete surface to the rebar surface is modeled and predicted by Concrete-Compass (Figures

9-11). The effect of stirrups on the residual bond strength is also accounted for in the software (Figure 12).

The powerful applications of Concrete-Compass are truly unlimited in engineering design, concrete corrosion prediction and modeling, cathodic protection design and optimization, and remaining life prediction of RC structures under the various service environments.

Click here to contact us for licensing details and experience the power of Concrete-Compass. |

|

Concrete-Compass, giving you the right directions in Concrete Corrosion Prediction and Modeling |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |

Concrete corrosion refers to corrosion of the reinforcing steels in concrete structures such as buildings, car parks, road beds, bridge decks and bridge substructures, concrete marine structures, and many industrial facilities. Concrete corrosion is a world-wide problem that leads to cracking, staining, spalling, and ultimately structural weakness. Concrete-Compass is the only device and OS independent software tool on the market for concrete corrosion modeling and life prediction of reinforced concrete structures. Designers, architects, engineers, consultants, operation personnel, maintenance and inspection engineers can quickly determine the concrete corrosion rate, the crack width at different depth of concrete cover from the concrete surface to the reinforcing steel, and the remaining life of the RC structure, anytime, anywhere, on any device running any OS without the need to install or download anything. Concrete-Compass also predicts the effectiveness of cathodic protection and the minimum cathodic protection polarization required to reduce the corrosion rate to a level that can meet the design life of the RC structure. Concrete-Compass software models the effects of the following critical factors on concrete corrosion:

Concrete corrosion refers to corrosion of the reinforcing steels in concrete structures such as buildings, car parks, road beds, bridge decks and bridge substructures, concrete marine structures, and many industrial facilities. Concrete corrosion is a world-wide problem that leads to cracking, staining, spalling, and ultimately structural weakness. Concrete-Compass is the only device and OS independent software tool on the market for concrete corrosion modeling and life prediction of reinforced concrete structures. Designers, architects, engineers, consultants, operation personnel, maintenance and inspection engineers can quickly determine the concrete corrosion rate, the crack width at different depth of concrete cover from the concrete surface to the reinforcing steel, and the remaining life of the RC structure, anytime, anywhere, on any device running any OS without the need to install or download anything. Concrete-Compass also predicts the effectiveness of cathodic protection and the minimum cathodic protection polarization required to reduce the corrosion rate to a level that can meet the design life of the RC structure. Concrete-Compass software models the effects of the following critical factors on concrete corrosion: