|

Home |

Consulting |

Corrosion Training |

Expert Witness |

Failure Analysis |

Design Review |

Corrosion Test |

Corrosion Software

|

Coatings

|

Materials Selection |

Cathodic Protection |

>>> |

|

Corrosion Modeling Software and Corrosion Prediction Software Series CO2Compass®: CO2 Corrosion Prediction, Modeling, Assessment, and Solutions The Ultimate Predictive Software Solution to Costly CO2 Corrosion Version 25.5

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

CO2Compass is the next generation predictive software for CO2 corrosion prediction and CO2 corrosion modeling. Unique features of CO2Compass not found in any other commercially available CO2 prediction software: |

|

|

1. Performance Guarantee

WebCorr is the only corrosion software developer who offers you a performance guarantee. We stand behind the accuracy of our corrosion software. If at any time during the license period, the corrosion rates predicted by WebCorr's corrosion prediction software and corrosion modeling software are not closer to the measured values than the values predicted by any other corrosion prediction and corrosion modeling software on the market, we will refund the pro-rated license fee to you. It is that simple. No other corrosion prediction software and corrosion modeling software developer offers you this performance guarantee.

2. Unparalleled Functionality Practical Solutions: Traditional CO2 corrosion prediction and CO2 corrosion modeling software are limited in their capability to the prediction of the corrosion rate only, without due consideration to the CO2 corrosion control strategy under the prevailing operating conditions of a pipeline or production tubing. CO2Compass, the next generation CO2 corrosion prediction and corrosion modeling software goes far beyond the prediction of the corrosion rate – it utilizes machine learning and cloud computing to optimize a particular CO2 corrosion control strategy with specific and quantitative control targets under the prevailing operating conditions of a pipeline or production tubing. Significant cost savings can be realized for asset owners at both the design and operation phases of pipelines or production tubing. CO2Compass is not just for CO2 corrosion prediction, it also provides users with expert guidance on practical solutions for mitigating CO2 corrosion. Based on the predicted CO2 corrosion rate, the prevailing operating conditions, the flow regimes, and the water analysis results, CO2Compass makes an overall assessment of the complete system and generates recommendations for CO2 corrosion mitigation strategies and precise control targets for CO2 Removal, Glycol Injection, pH Stabilization, and Water Removal. Other prediction results include the following:

The screenshot below shows that the risk of elemental sulfur corrosion is high, with an increase in corrosion rate of 780.09% under the prevailing operating conditions when elemental sulfur is present. No other CO2 corrosion modeling software offers this function.

The risks of mercury on liquid metal embrittlement (LME), health and safety are also assessed by CO2Compass. The following screenshot shows that the mercury risk is high with liquid metal embrittlement being highly likely and detailed speciation, frequent monitoring and stringent controls are required to address the health and safety concerns. No other CO2 corrosion modeling software offers this function.

Under the Corrosion Control Options in CO2Compass, the critical levels of four major parameters (CO2 content, glycol concentration and injection rate, pH and bicarbonate dosage, and water content) that can independently reduce the predicted corrosion rate to meet the design value are all calculated automatically. CO2Compass gives the user effective and powerful tools to assess and optimize a particular CO2 corrosion mitigation strategy with precise control targets. For example, CO2 removal can be used alone or in combination with other options such as corrosion inhibition, glycol injection, and pH stabilization to reduce the predicted corrosion rate to a level that will meet the design requirement, thus extending the applicability of carbon steels to situations that might otherwise require the use of CRAs. No other CO2 corrosion prediction software offers this function. This unique feature alone can literally save asset owners millions of dollars. A real-life case study is presented in the 5-day course on "CO2 Corrosion Modeling for the Prediction of Internal Corrosion in Oil & Gas Pipelines and Production Tubing".

Scale Prediction: CO2Compass has a built-in module for the prediction of scaling tendency. The seamless integration of the scale prediction engine into the rigorous thermodynamic framework for corrosion modeling makes CO2Compass a powerful tool in assessing and mitigating the risks of both corrosion and scaling at the same time and with minimal effort from the user. Saturation indices for scales commonly encountered in oil and gas production, processing and transmission are calculated automatically based on the prevailing operating conditions and water analysis results. No other CO2 corrosion modeling software offers this feature.

In-situ pH Calculator:

3. Unmatched Usability: CO2Compass was designed with the user in mind. Experience the industry's first cross-platform and device-independent CO2 corrosion modeling and prediction application on your tablets, notebooks, and desktops, at any time and anywhere, in the office or in the field. No installation files to download, no browser plug-ins required, no USB dongles to carry around, and no license keys to transfer from one PC to another. CO2Compass simply works on any device running any OS. All you need is an internet browser. Unlike the black-box style of other CO2 corrosion modeling software, CO2Compass gives the user complete and direct control over the modeling of the effects of scaling, oil wetting, glycol, CO2 fugacity, in-situ pH, liquid velocity, organic acids, H2S, corrosion inhibitor availability, and inhibiting efficiency with user-controlled ON/OFF switches and direct inputs overriding the default settings. No other CO2 corrosion prediction and CO2 corrosion modeling software offers these powerful features.

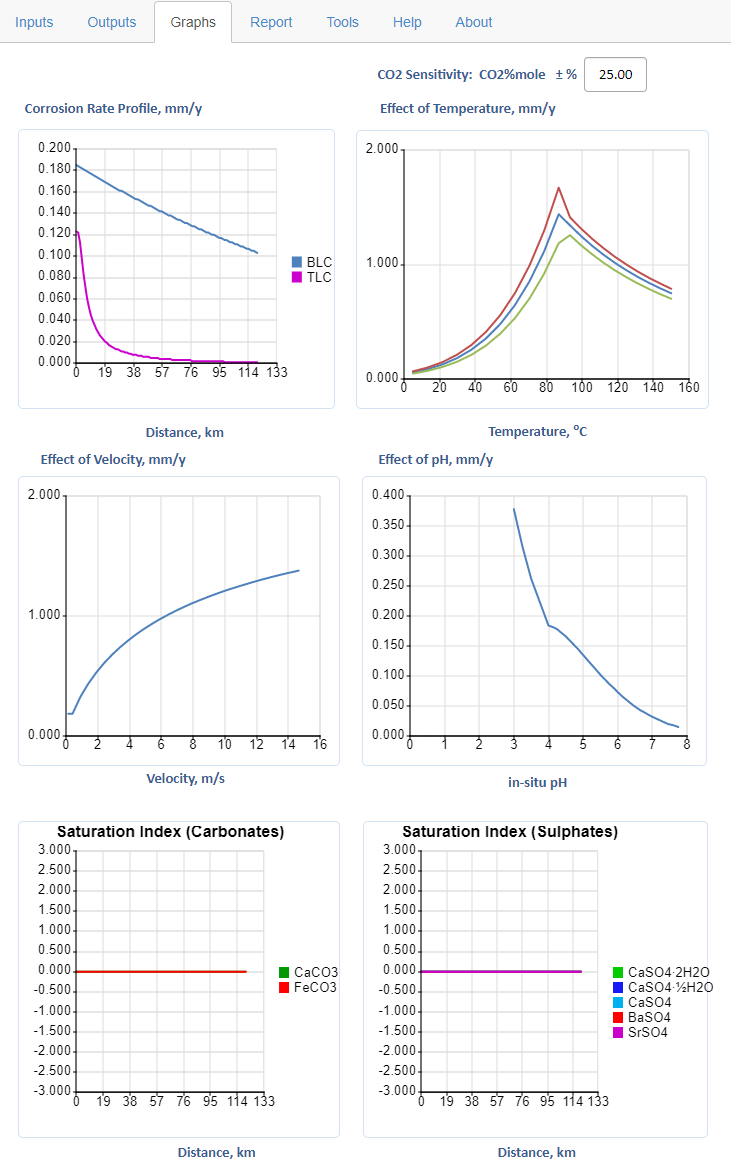

Automatically generated and dynamically updated graphs are plotted in real-time as the user makes adjustments to the input parameters. These plots include corrosion rate profile, effect of temperature, effect of velocity, and effect of pH on the predicted CO2 corrosion rates for both top of line corrosion (TLC) and bottom of line corrosion (BLC). Saturation indices of carbonates and sulphate scales are also plotted. A clean and concise report is automatically generated and dynamically updated in real-time as you enter or change the input parameters.

A Brief Overview of CO2Compass

CO2Compass has a super-clean and super-efficient user interface that instantly responds to changes in user inputs. You do not need to select the input parameter range before entering the input parameter value or wait for flashy and sluggish screens to update the displayed calculation results. In CO2Compass, all input parameters are presented under the Inputs Tab. All calculation results are presented under the Outputs Tab. Users have complete control over the modeling process by directly overriding the default settings for parameters such as in-situ pH, liquid velocity, FeCO3/Fe3O4 scale protection, FeS scale protection, oil wetting, glycol effect, CO2 fugacity, inhibitor efficiency, and inhibitor availability. Refer to the screenshots below for details.

Unique features in CO2Compass not found in any other commercial CO2 prediction and CO2 corrosion modeling software include:

The Corrosion Risk Category, the Corrosion Dominating Process, the Elemental Sulfur Corrosion Risk, the Mercury Risk including the likelihood of liquid metal embrittlement (LME), the Inhibitor Effectiveness, measured by the Inhibitor Likelihood Success Score (ILSS), the Inhibitor Risk Category and typical inhibitor dosage are automatically generated as outputs.

Under the "Corrosion Control Options", the critical levels of pCO2, glycol, pH and H2O that can reduce the corrosion rate independently to meet the design requirement are calculated automatically based on the prevailing conditions. Users have the option to use the ON/OFF switches and adjust the input parameters to optimize a particular CO2 corrosion mitigation strategy. For example, glycol injection and pH stabilization can be optimized to permit the use of carbon steels in situations where CRAs may have to be considered. Refer to the image above for details. In this particular case shown in the image above, the predicted CO2 corrosion rate with corrosion inhibitor at 90% efficiency and 95% availability is 0.18 mm/y, which is still above the design limit of 0.1 mm/y. CO2Compass makes an overall assessment of the situation and automatically generates CO2 corrosion control options available to the user:

(1) CO2 removal alone can be used to reduce the inhibited CO2 corrosion rate to the design limit. The maximum CO2 partial pressure allowed is 0.400 bar or the maximum concentration of CO2 allowed is 0.800%. Note that reducing the total system pressure will also lower the partial pressure of CO2;

(2) glycol injection alone can be used to reduce the inhibited CO2 corrosion rate to the design limit. The minimum concentration of glycol required is 31.83% or the minimum injection rate is 491 kg per MMSM3 gas;

(3) pH stabilization alone can be used to reduce the inhibited CO2 corrosion rate to the design limit. The minimum pH required is 5.65 and the minimum concentration of bicarbonate to achieve the required pH is 340 ppm;

(4) water removal alone can also be used to reduce the inhibited CO2 corrosion rate to the design limit. The maximum water content in both the gas phase and the liquid phase should not exceed 99 kg/MMSM3; each of the 4 options can independently reduce the inhibited corrosion rate to the design limit;

(5) under the Material Selection Options, CO2Compass calculated the corrosion allowance (CA) required for carbon steel (5.54 mm) if none of the 4 corrosion control options is used.

By varying the input parameters, users can optimize a particular CO2 corrosion control strategy with combined use of available options, thus extending the applicability of carbon steels to situations that might otherwise require the use of CRAs. This unique feature alone can literally save asset owners millions of dollars. A real-life case study is presented in the 5-day course on "CO2 Corrosion Modeling for the Prediction of Internal Corrosion in Oil & Gas Pipelines and Production Tubing".

Under the Graphs Tab, automatically generated and dynamically updated graphs are plotted in real-time as the user makes adjustments to the input parameters. Users have instant access to the bigger pictures of CO2 corrosion under the prevailing operating conditions:

In the screenshot below, users can quickly and conveniently perform CO2 sensitivity analysis right under the Graphs Tab without going back to the Inputs screen. The top right corner has an input window where users can enter a percentage of the current CO2 content, CO2Compass plots two additional data sets, one for current CO2 content minus the entered percentage (the lower curve in the effect of temperature plot), and one for current CO2 content plus the entered percentage (the upper curve). For example, if the current prevailing CO2 content is 4% mole, and 25 (%) is entered into the window, CO2Compass plots the lower curve for 3% mole (4-4x0.25=3) and upper curve for 5% mole (4+4x0.25=5). The resultant corrosion rates at 3%, 4%, and 5% CO2 are instantly displayed on the temperature plot. A quick glance at the plot will reveal the impact of the change in CO2 content on the corrosion rate. Users can make use of this feature to quickly assess the impact of off-spec gas on the corrosion risk of the pipelines and associated facilities, and more importantly to define an acceptable integrity operating window in terms of the plus/minus percentage of the current CO2 content under the prevailing operating conditions.

Under the report Tab, a clean and concise report is automatically generated and dynamically updated in real‐time as you enter or change the input parameters. Users simply print out a hardcopy or save the the report as a PDF file.

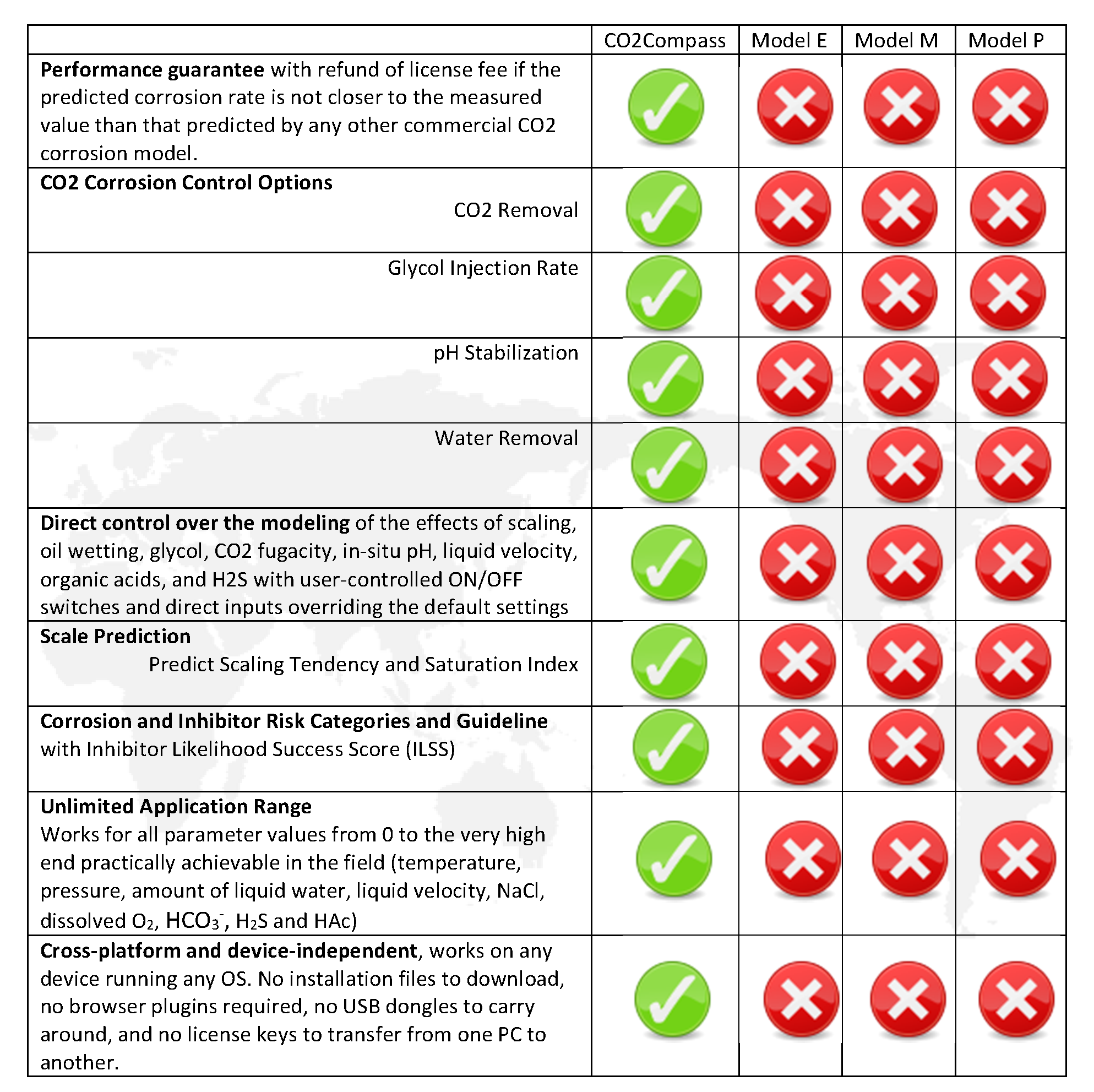

CO2 Corrosion Modeling Software Feature Comparison Chart

|

|

|

CO2Compass has the following special editions:

WebCorr can work with you to customize an existing software or develop a new one to meet your specific requirements. Click here to contact us for licensing details and experience the power of CO2Compass. CO2Compass, giving you the right directions in the fight against CO2 Corrosion. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |