|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Prediction Software and Corrosion Modeling Software VPC-Compass®: Prediction and Modeling of Vapor Phase Corrosion in Closed Systems

A High Value Software Solution to Costly Corrosion

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of VPC-Compass |

|

|

VPC-Compass is the only device and OS independent software tool on the market for the prediction and modeling of vapor phase corrosion in closed systems such as storage tanks, pipelines, process vessels, and other industrial facilities. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly determine the corrosion rate of steel and the risk rankings of internal corrosion in the vapor phase of a closed system, anytime, anywhere, on any device running any OS without the need to install or download anything. VPC-Compass also predicts the relative humidity in the closed system, the partial pressure of water vapor, the saturated water vapor pressure, the dew point of water vapor, the thickness of moisture film on the internal surface, the surface conductivity of the moisture film, the average metal loss and the maximum pit depth over the lifetime of the closed system.

Figures below show the screen shots of VPC-Compass.

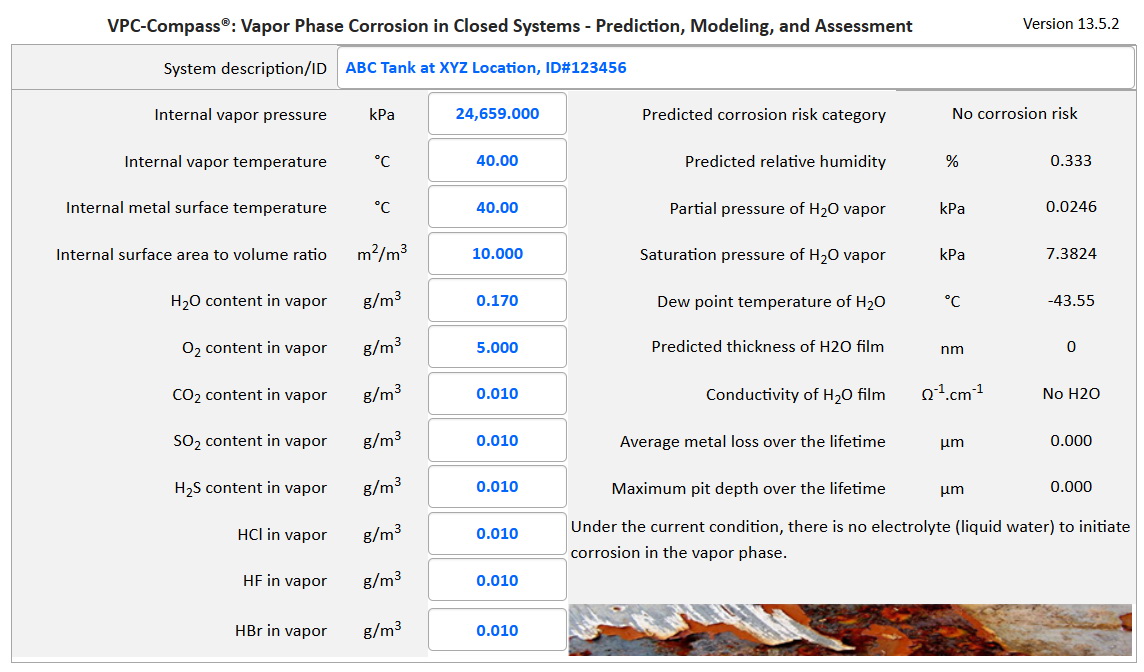

Figure 1 VPC-Compass predicts the risk of internal corrosion in the vapor phase (no corrosion risk).

Under the prevailing conditions shown in Figure 1 above, there is no risk of internal corrosion in the vapor phase as there is no electrolyte (liquid water) to support the corrosion process in the vapor phase. There is no moisture film on the internal surface and the surface is non-conductive.

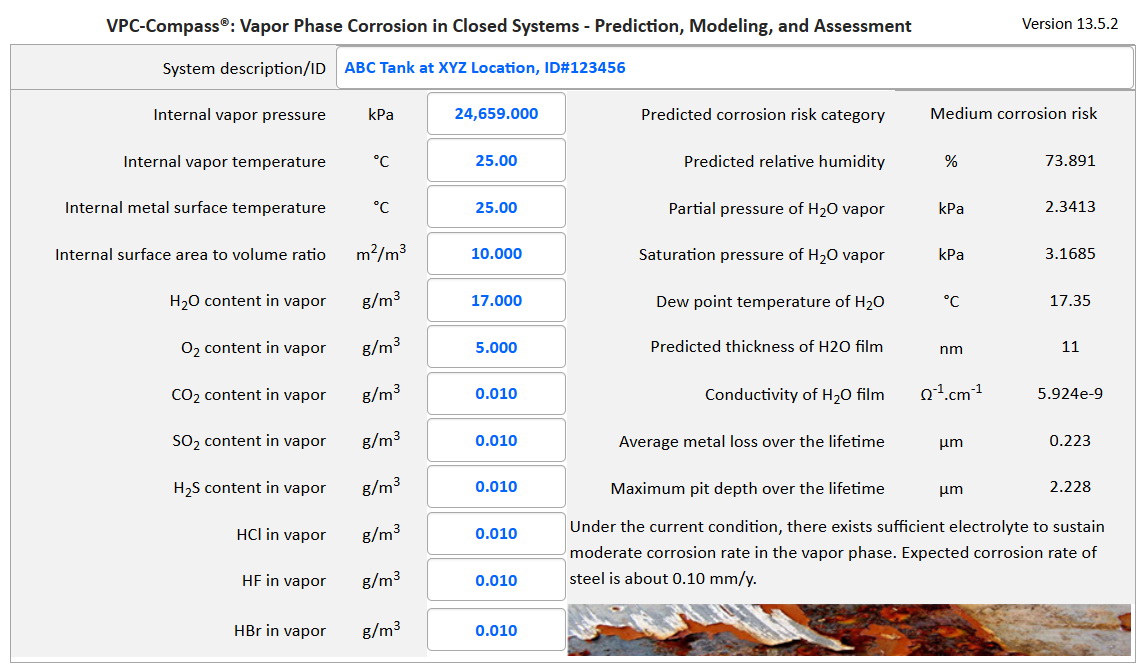

Under the prevailing operating condition in Figure 2, VPC-Compass predicts that there is a medium risk of internal corrosion in the vapor phase as there exists sufficient electrolyte (liquid water) to sustain a moderate corrosion rate in the vapor phase. The predicted moisture film thickness is 11 nm and the surface conductivity is 5.924 x 10-9 Ω-1.cm-1. The average metal loss over the lifetime of the closed system is 0.223 µm, the maximum pit depth over the lifetime of the closed system is 2.228 µm, and the expected corrosion rate of steel is about 0.1 mm/y.

Figure 2 VPC-Compass predicts the risk of internal corrosion in the vapor phase (medium corrosion risk).

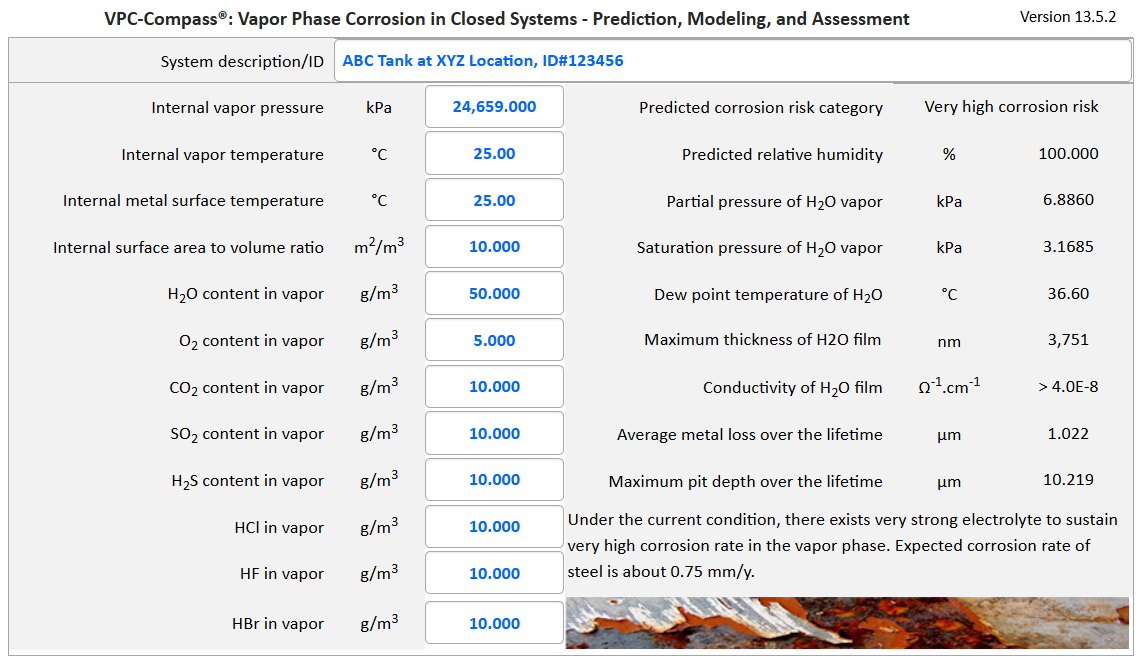

Under the prevailing operating condition shown in Figure 3, there is a very high risk of internal corrosion in the vapor phase.

Figure 3 VPC-Compass predicts the risk of internal corrosion in the vapor phase (very high corrosion risk).

The powerful applications of VPC-Compass are truly unlimited in engineering design, internal corrosion prediction and risk assessment, materials selection, trouble-shooting process-related issues and failure analysis of components and systems. A special edition of VPC-Compass for the microelectronics and semiconductor industry is also available.

Click here to contact us for licensing details and experience the power of VPC-Compass. |

|

VPC-Compass, giving you the right directions in Vapor Phase Corrosion Prediction and Risk Assessment |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |