|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

VPC-Compass-SE®: Prediction and Modeling of Corrosion in Microelectronic Packages Version 9.20

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of VPC-Compass-SE |

|

|

VPC-Compass-SE is the only device and OS independent software tool on the market for the prediction and modeling of corrosion in microelectronic packages. Designers, OEM engineers, QA/QC and inspection engineers can quickly determine the the risk rankings of corrosion and other reliability issues in microelectronic packages such as electrochemical migration (ECM), dendrite formation/metallic treeing, and surface conductivity. VPC-Compass-SE also predict the relative humidity or the moisture content in the internal cavity, the dew point temperature in the cavity, the number of monolayers of water on the internal surface, the thickness of moisture film on the internal surface, and the surface conductivity of the moisture film. VPC-Compass-SE works on any device running any OS without the need to install or download anything.

Figures below show the screen shots of VPC-Compass-SE.

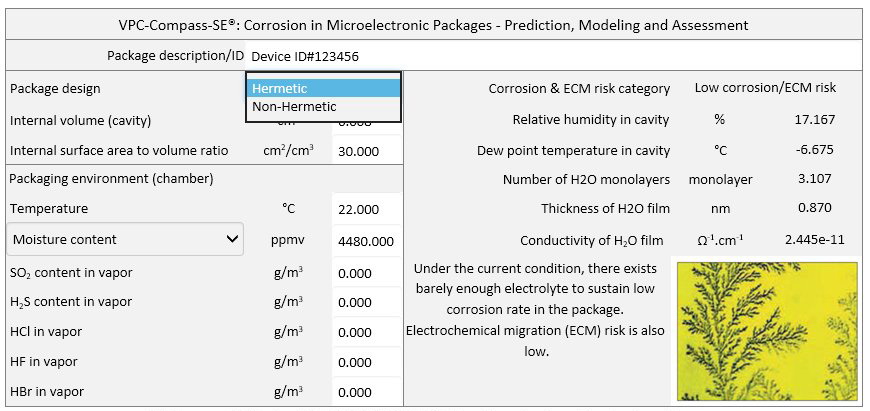

Figure 1 VPC-Compass-SE predicts the risk of corrosion and electrochemical migration (ECM): design parameters

Users of VPC-Compass-SE start by selecting the package design from the dropdown list (hermetic and non-hermetic). Input parameters include the internal volume of cavity/headspace and the internal surface area (in cm2) to the volume (in cm3) ratio, as shown in Figure 2 below.

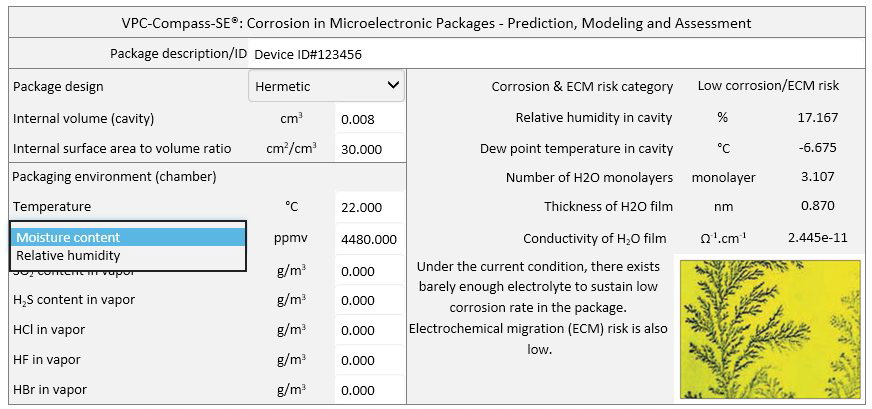

Figure 2 VPC-Compass-SE predicts the risk of corrosion and electrochemical migration (ECM): environmental parameters

Environmental parameters include temperature, moisture content/relative humidity, and other gases. If moisture content (in ppmv) is used as input, the relative humidity in the cavity will be predicted by VPC-Compass-SE; if the relative humidity is used as the input, the moisture content in the cavity will be predicted by VPC-Compass-SE, as shown in Figure 3 below.

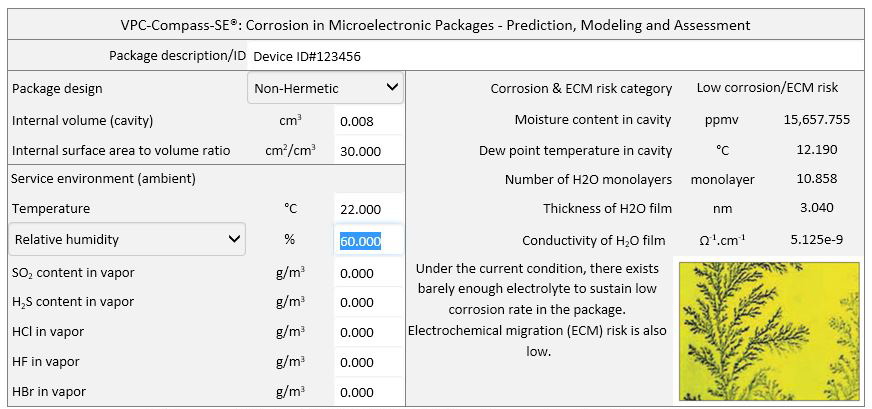

Figure 3 VPC-Compass-SE predicts the risk of corrosion and electrochemical migration (ECM): input RH

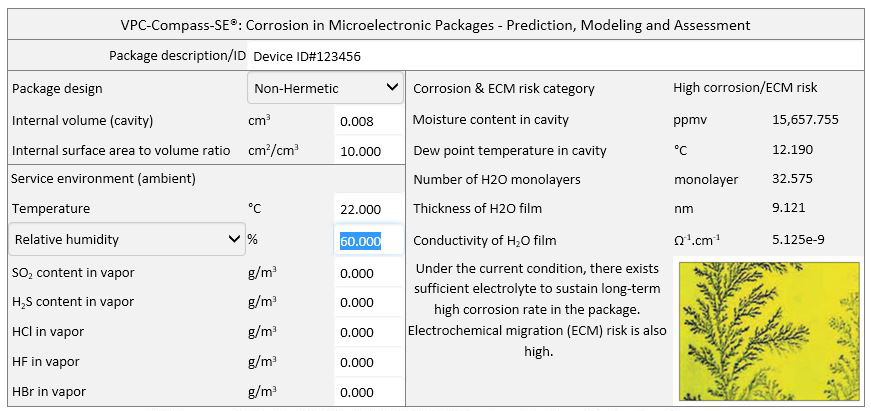

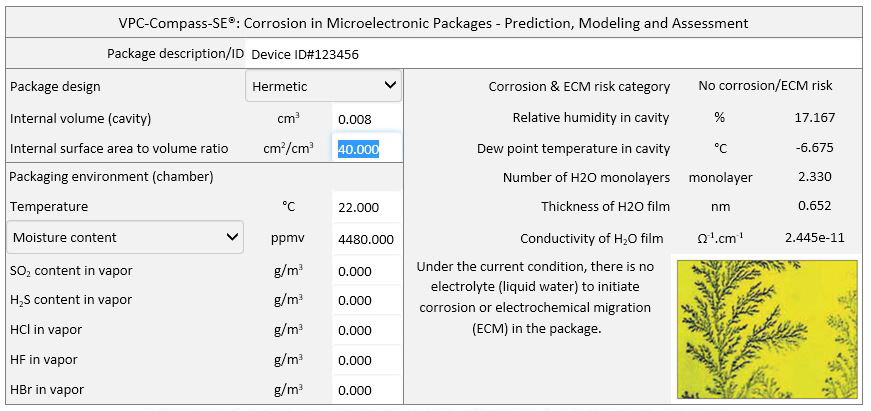

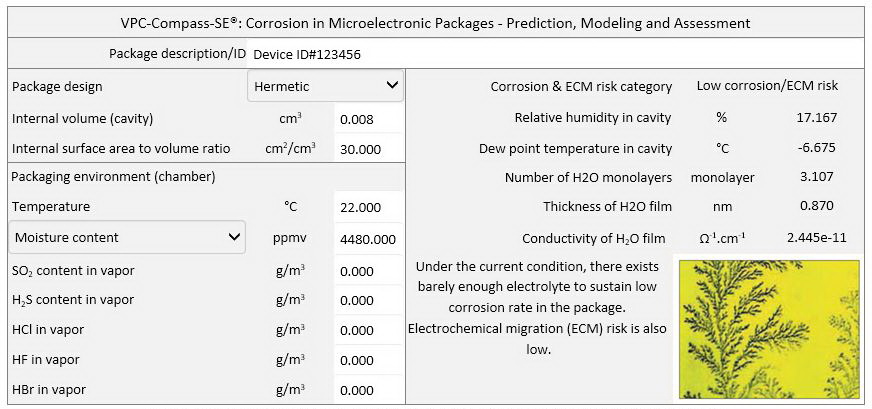

Under the specified package design and environmental conditions shown in Figure 3 above, the risk of corrosion and electrochemical migration (ECM) is low as there exists barely enough electrolyte (moisture) to support the corrosion and/or ECM process. The predicted moisture content in the internal volume is 15,658 ppmv, the predicted dew point temperature is 12.19°C, the predicted number of monolayers of water on the internal surface is 11, the thickness of moisture film is 3 nm, and the conductivity of surface moisture is 5.12 x 10-9 Ω-1.cm-1. When the internal surface area to volume ratio changes from 30 to 10 (Figure 4 below), the risks of corrosion and electrochemical migration are high. If, however, the internal surface area to volume ratio changes to 40 (Figure 5), there is no risk of corrosion or electrochemical migration.

Figure 4 VPC-Compass-SE predicts the risk of corrosion and electrochemical migration (ECM): effect of surface area to volume ratio, high risk

Figure 5 VPC-Compass-SE predicts the risk of corrosion and electrochemical migration (ECM): effect of surface area to volume ratio, no risk

Figure 6 VPC-Compass-SE predicts the risk of corrosion and electrochemical migration (ECM).

Under the specified package design and environmental conditions shown in Figure 6 above, the risk of corrosion and electrochemical migration is low as there exists barely enough electrolyte (moisture) to support the corrosion and/or ECM process. The predicted relative humidity in the internal volume is 17%, the predicted dew point temperature is -6.675°C, the predicted number of monolayers of water on the internal surface is 3, the predicted thickness of moisture film is 0.87 nm, and the predicted conductivity of surface moisture is 2.445 x 10-11 Ω-1.cm-1.

The powerful applications of VPC-Compass-SE are truly unlimited in packaging design design, corrosion prediction and reliability assessment, process control, trouble-shooting and failure analysis of microelectronic components and systems.

Click here to contact us for licensing details and experience the power of VPC-Compass-SE. |

|

VPC-Compass-SE, giving you the right directions in Prediction and Modeling of Corrosion in Microelectronic Components |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |