|

Home |

Consulting |

Training |

Expert Witness |

Failure Analysis |

Design Review |

Corrosion Test |

Corrosion Software

|

Coatings

|

Materials Selection |

Cathodic Protection |

>>> |

|

Corrosion Modeling Software and Corrosion Prediction Software Series ACMF-Compass®: Modeling and Prediction of the Effects of AC and Magnetic Field on Metal Corrosion Effective Software Solution to Corrosion under the Influence of AC and/or Magnetic Field Version 9.20

Anytime Anywhere Any Device Any OS

No USB dongles No

installation

No Browser Plug-ins

Contact Us for Licensing Details

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training

& Support |

CorrCompass |

|

|

Overview of ACMF-Compass: Modeling and Prediction of the Effects of AC and Magnetic Field on Metal Corrosion |

|

|

AC corrosion has been a well known problem in the pipeline industry since the early 1900s. The body of literature indicates that AC corrosion exists in many industries from plumbing systems, power generation and process industries to electronics and semiconductor industry where capacitive coupling can lead to AC induced corrosion in mission critical power electronics cooling systems. In many engineering applications, metals are used within magnetic fields of various strengths and are exposed to a corrosive environment at the same time. Magnetic field may cause changes in the mass transfer of reactant or reaction product. Changes in mass transport arise as a result of solution flow induced by magnetohydrodynamics, the interaction of the electric current in the solution and the applied magnetic field. ACMF-Compass is the only device and OS independent predictive software on the market for the modeling and prediction of the effects of AC and magnetic field on metal corrosion. Designers, engineers, consultants, maintenance and inspection personnel can quickly assess and quantify the impact of AC and magnetic field on the corrosion rate and the remaining life for a range of materials including:

Aluminum Alloys:

AA1100 Bare

If you cannot find the material of your interest in the above list, do let us know through the Contact Us link and we will conduct the necessary tests to generate the required data for inclusion in the software, free of charge for licensed users of ACMF-Compass.

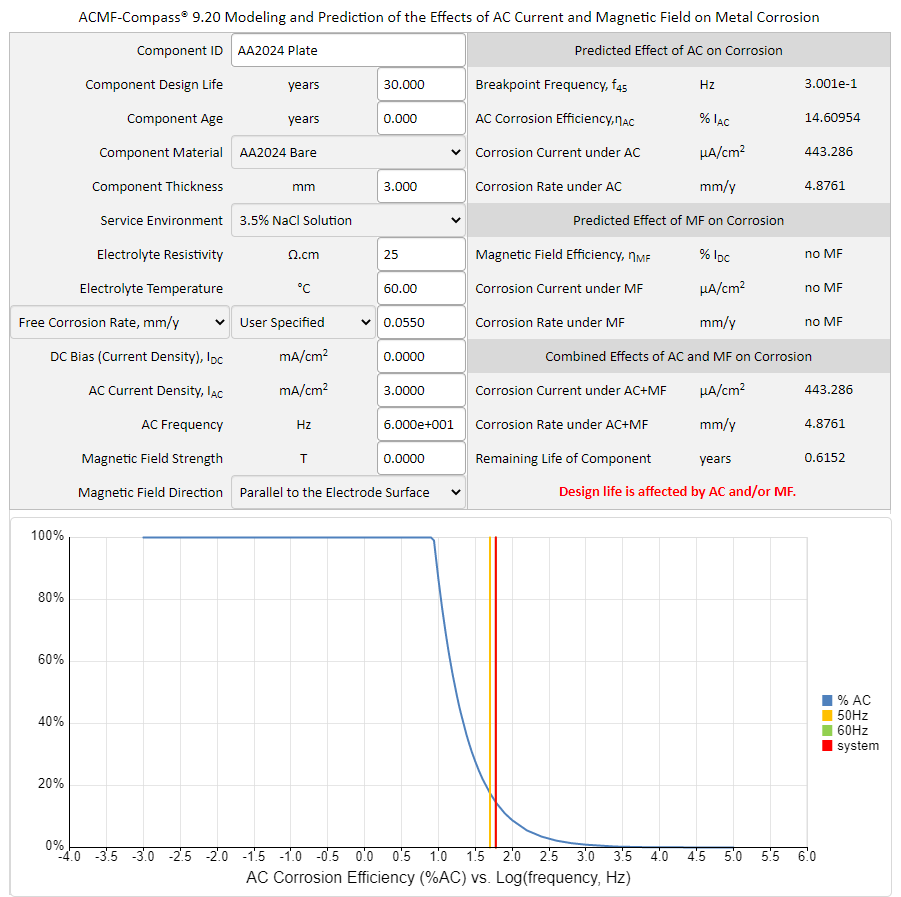

Under the conditions shown in Figure 1 below, at AC current density of 0.65 mA/cm2, ACMF-Compass predicts that the AC corrosion efficiency (percent of AC current to equivalent amount of DC current) is 0.268%, the corrosion current density under the influence of AC is 6.745 uA/cm2. The corrosion rate is 0.0742 mm/y. The remaining life is 40 years. ACMF-Compass predicts that under the current conditions, the design life of 30 years can be achieved. However, if the AC current density is increased to 3 mA/cm2, as shown in Figure 2 below, ACMF-Compass predicts that the AC corrosion efficiency is increased to 14.61%, the corrosion current density under the influence of AC is increased to 443.286 uA/cm2. The corrosion rate is increased to 4.876 mm/y. The design life of 30 years can not be achieved due to the influence of AC current on the corrosion of aluminum alloy 2024.

Figure 1 ACMF-Compass models the effect of AC on corrosion of metals.

Figure 2 ACMF-Compass models the effect of AC on corrosion of aluminum alloy 2024 at 3 mA/cm2.

The prediction output includes a plot of the AC efficiency vs. the AC frequency for the metal in contact with the selected electrolyte. The available electrolytes in the software for selection include:

Low Vacuum (>10 Pa)

If you cannot find the service environment (electrolyte) of your interest in the above list, do let us know through theContact Us link and we will conduct the necessary tests to generate the required data for inclusion in the software, free of charge for licensed users of ACMF-Compass.

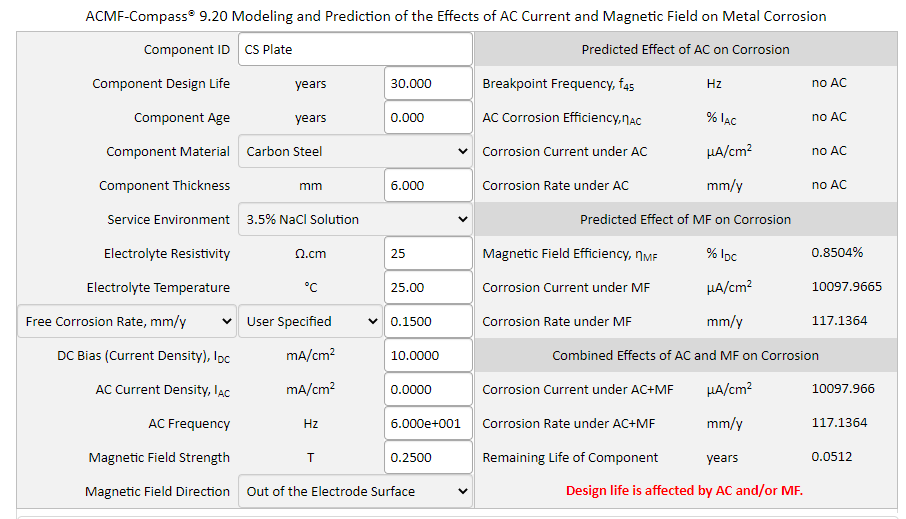

Figure 3 shows the modeling results for the effect of magnetic field on corrosion of carbon steel in 3.5% NaCl solution. The magnetic field efficiency (percent of the DC bias) is predicted to be 0.85%.

Figure 3 ACMF-Compass models the effect of magnetic field on metal corrosion

Using ACMF-Compass is as easy as 1-2-3: (1) Select the component material from the dropdown list and enter the design data; (2) Select the electrolyte and enter the AC and/or Magnetic Field data; (3) Review the prediction results.

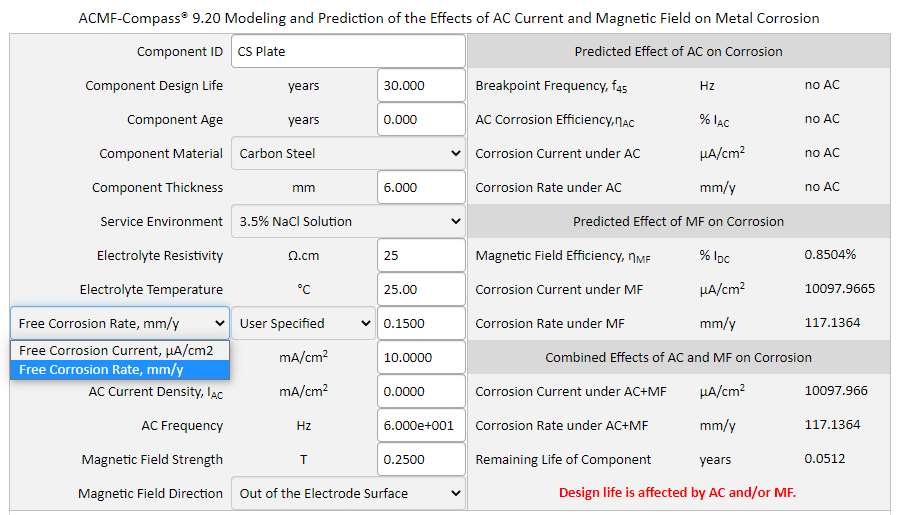

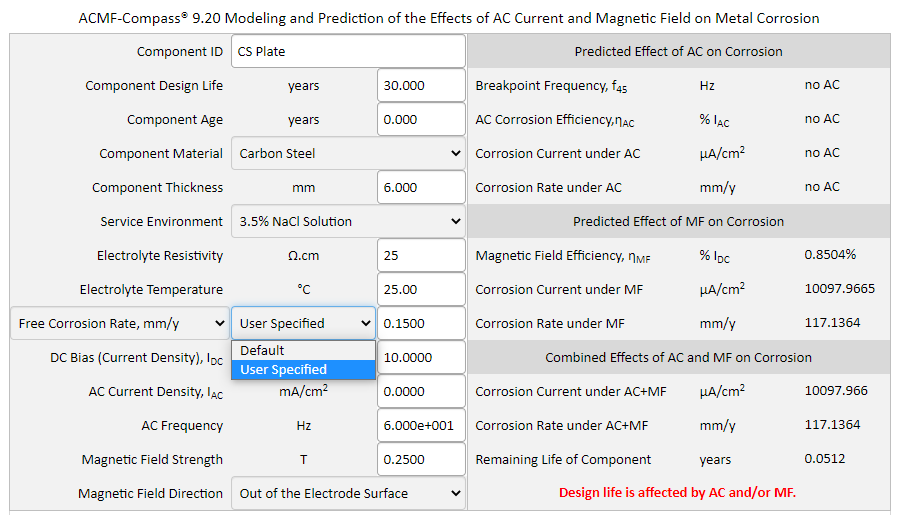

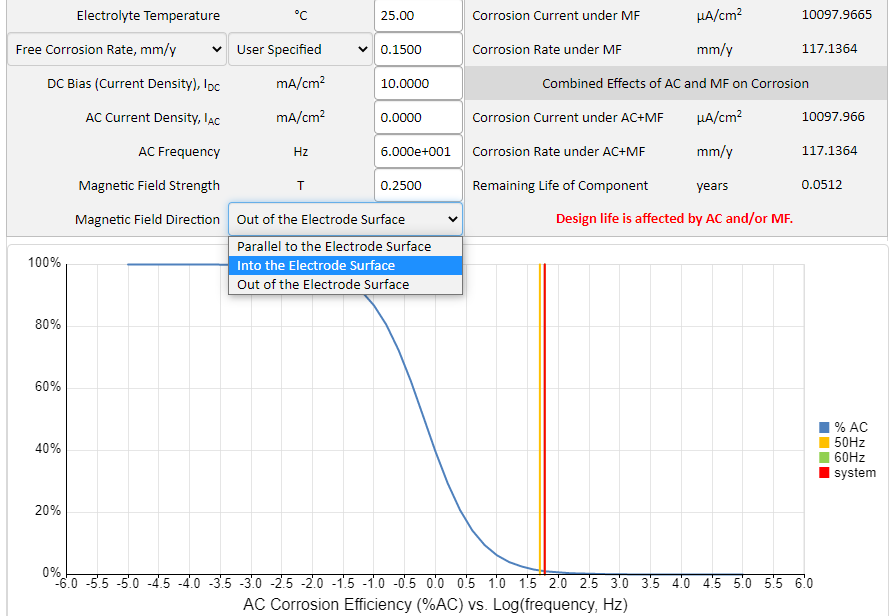

Users of ACMF-Compass have the option to specify the free corrosion rate (corrosion free from the influence of AC and MF) in either uA/cm2 or mm/y (Figure 4). If the free corrosion rate for the selected metal in the selected electrolyte is not available, the default option (Figure 5) will trigger the predictive engine in ACMF-Compass to compute the free corrosion rate. The effect of magnetic field direction on the corrosion rate is also modeled in ACMF-Compass (Figure 6).

Figure 4 ACMF-Compass allows users to select free corrosion rate in uA/cm2 or mm/y.

Figure 5 ACMF-Compass can determine the free corrosion rate if user data is not available.

Figure 6 ACMF-Compass models the effect of magnetic field direction on the corrosion rate of metals.

The powerful applications of ACMF-Compass are truly unlimited in engineering design, materials selection, process operation, inspection and maintenance, modeling and prediction of metal corrosion under the influence of AC and/or magnetic field. Click here to contact us for licensing details.

WebCorr can customize ACMF-Compass for your specific systems. |

|

|

ACMF-Compass, giving you the right directions in managing corrosion under the influence of AC and magnetic field. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. WebCorr Corrosion Consulting Services. All rights reserved. |