|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series

S-Compass®: Modeling and Prediction of High Temperature Sulfidation/Sulfidic Corrosion/H2-H2S Corrosion Version 9.20

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of S-Compass |

|

|

Sulfidation or sulfidic corrosion refers to the corrosion of a metal resulting from reaction with sulfur compounds in high temperature environments such that a surface sulfide scale forms often with sulfur penetrating somewhat below the original thickness. In the presence of H2/H2S, sulfidation is also referred to as H2-H2S corrosion. S-Compass is the only device and OS independent software tool on the market for the modeling and prediction of low temperature elemental sulfur corrosion and high temperature sulfidation (sulfidic) corrosion. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine:

S-Compass is a cloud-based software that works on any device running any OS without the need for users to install or download anything.

How to determine the operating temperature limits for steels in H2-free and H2-H2S services to avoid sulfidation, sulfidic corrosion, H2-H2S corrosion?

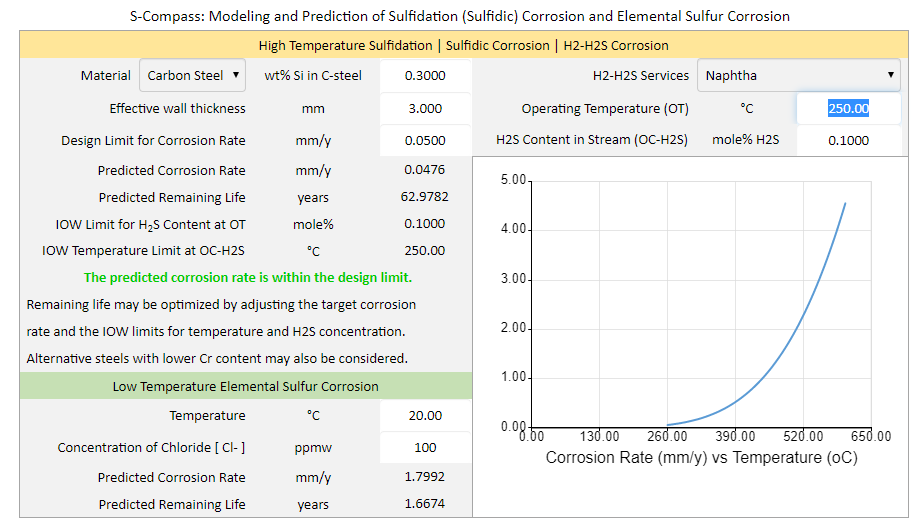

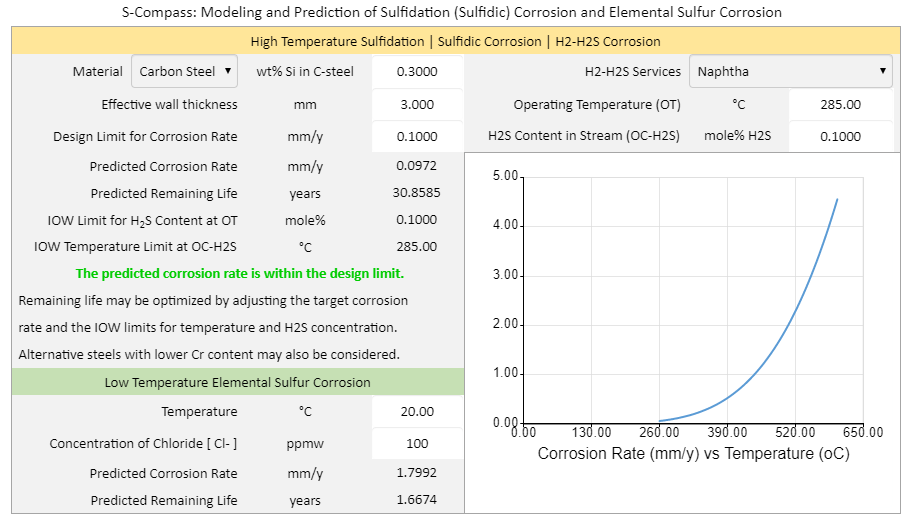

Figure 1 S-Compass predicts high temperatures sulfidation, sulfidic corrosion, H2-H2S corrosion and low temperature elemental sulfur corrosion.

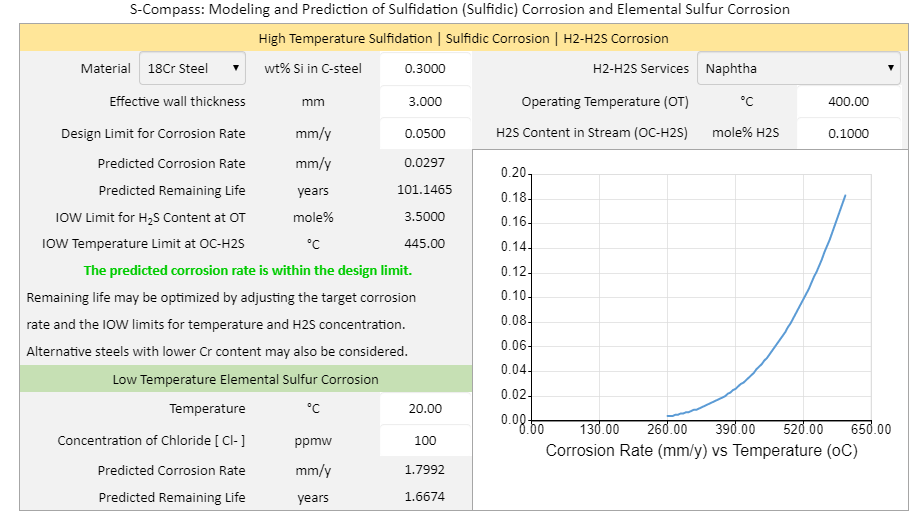

How to select alloy steels for high temperature sulfidation resistance? How to determine the integrity operating windows for H2-free and H2-H2S services in sulfur-containing streams? How to assess the susceptibility of an alloy steel to high temperature sulfidation, sulfidic corrosion, H2-H2S corrosion? Under the prevailing temperature and hydrogen sulfide concentration shown in Figure 1 above, carbon steel is not resistant to sulfidation. The first mitigation measure recommended by S-Compass is to change the operating temperature (OT) to the IOW limit determined by S-Compass (250oC). As shown in Figure 2, the corrosion rate is now reduced to the design limit and the equipment will reach its remaining design life.

Figure 2 S-Compass Predicts the integrity operating window (IOW) for the operating temperature in H2-H2S service.

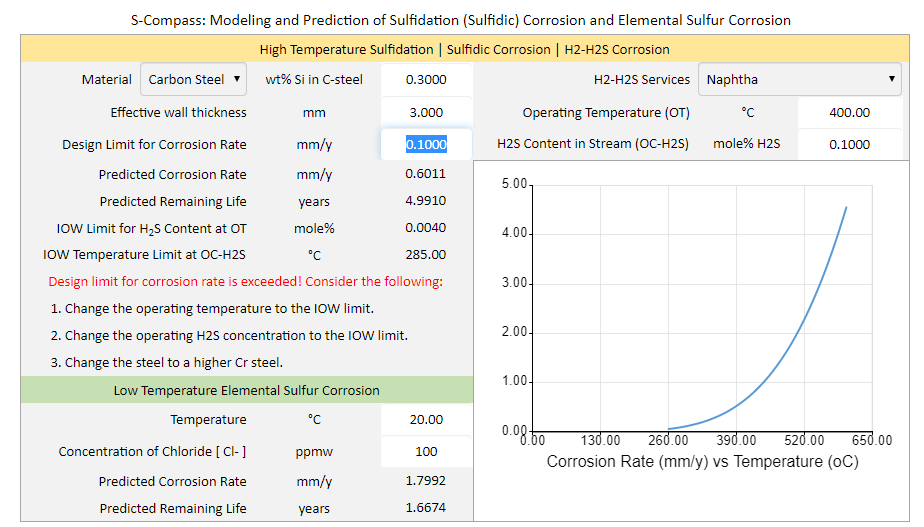

The second mitigation measure recommended by S-Compass is to change the operating H2S concentration to the integrity operating windows (IOW) limit predicted by S-Compass (0.0040 mole%). As shown in Figure 3 below, by reducing the operating H2S concentration to the predicted IOW (Figure 1), the sulfidic corrosion rate the selected material (carbon steel) is within the design limit.

Figure 3 Reducing the operating temperature to the predicted integrity operating windows (IoWs) for high temperature high pressure hydrogen services

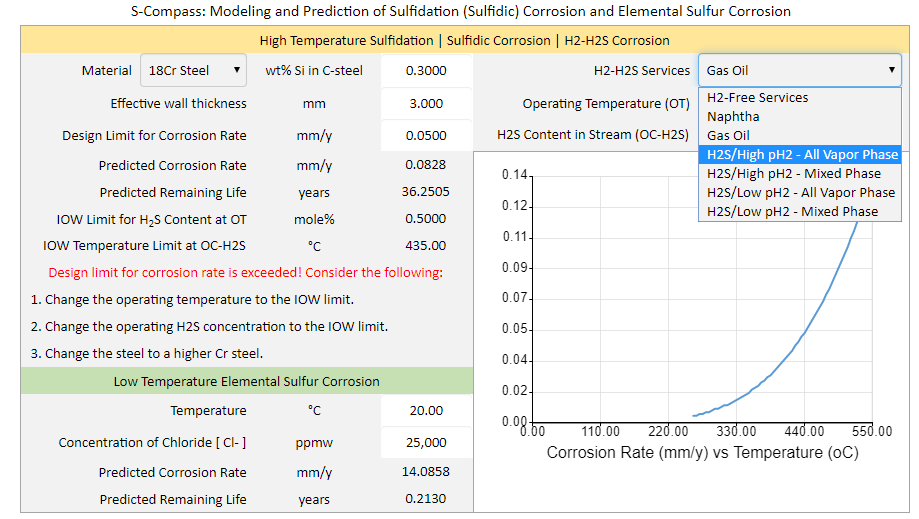

The third mitigation measure recommended by S-Compass (in Figure 1) is to select a higher Cr steel. As shown in figure 4, S-Compass has a dozen of alloy steels for users to choose from. Under the prevailing operating conditions shown in Figure 1, S-Compass predicts that 18Cr stainless steel meets the design limit for corrosion rate and shows excellent resistance to sulfidation, sulfidic corrosion or H2-H2S corrosion (Figure 5). Users of S-Compass software can select the H2-free and H2-H2S services for modeling and prediction of high temperature sulfidation, sulfidic corrosion, or H2-H2S corrosion (Figure 6).

Figure 4 S-Compass for evaluation and verification of alloy selection for high temperature sulfidation resistance.

Figure 5 S-Compass predicts that 18Cr stainless steel has excellent resistance to high temperature sulfidation.

Figure 6 S-Compass for modeling and prediction of high temperature sulfidation, sulfidic corrosion, H2-H2S corrosion in H2-free and H2-H2S services.

How to assess the effect of silicon on the sulfidation resistance of carbon steels in H2-free services? S-Compass is a powerful software that can provide instant answer to the above question. Silicon content is known to affect the sulfidation resistance of carbon steels. Under the prevailing operating conditions in Figure 7, the predicted corrosion rate for a carbon steel with 0.300 wt% Si in H2-free service is 0.945 mm/y. If the silicon content is reduced to 0.100 wt%, the predicted sulfidic corrosion rate is increased to 2.249 mm/y (Figure 8).

Figure 7 S-Compass software predicts the effect of silicon on the sulfidation resistance of carbon steels in H2-free services.

Figure 8 S-Compass software predicts the effect of silicon on the sulfidic corrosion resistance of carbon steels in H2-free services.

How to assess the remaining life of equipment and the IOW limits in H2-free and H2-H2S services?

S-Compass software predicts the sulfidation corrosion rate and the IOWs based on the prevailing operating conditions. In figure 1 above, the predicted sulfidic corrosion rate is 0.601 mm/y, the predicted remaining life under the prevailing operating conditions is 4.99 years, the IOW temperature limit is 250oC. If the design limit for corrosion rate or the acceptable corrosion rate is changed from 0.05 mm/y to 0.100 mm/y (Figure 9), the IOW temperature limit is increased to 285oC. Changing the prevailing temperature from 400oC to 285oC, the predicted equipment life is increased from 4.99 years to 30.86 years (Figure 10). S-Compass's unparalleled functionality in sulfidation modeling and prediction can help equipment designers, operations personnel, and maintenance engineers in their decision making with regard to materials selection, process control and optimization, life-cycle cost analysis, maintenance and inspection activities.

Figure 9 Assessing the effect of design limit on IOW temperature limit.

Figure 10 S-Compass predicts the effect of IOW temperature limit on the remaining life of equipment.

The powerful applications of S-Compass are truly unlimited in engineering design, materials selection, process operation, inspection and maintenance, modeling and prediction of low temperature elemental sulfur corrosion and high temperature sulfidation, sulfidic corrosion, H2-H2S corrosion in H2 services.

Click here to contact us for licensing details and experience the power of S-Compass. |

|

S-Compass, giving you the right directions in the Modeling and Prediction of Sulfidation, Sulfidic Corrosion, H2-H2S Corrosion and Elemental Sulfur Corrosion |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |

Under the prevailing operating conditions

shown in Figure 1 above, the corrosion rate of the selected material (carbon steel) in H2-H2S service (naphtha), is predicted to be 0.601 mm/y. The predicted remaining life of the equipment is 4.99 years. The safe temperature limit for the selected material, carbon steel, at the prevailing operating H2S concentration (OC-H2S) of 0.100 mole% is 250°C, the safe hydrogen sulfide concentration limit at the prevailing operating temperature (OT) of 400°C is 0.004 mole%. S-Compass determines that this material is not resistant to sulfidation at the prevailing operating conditions and recommends 3 mitigation measures to reduce the corrosion rate to the design limit.

Under the prevailing operating conditions

shown in Figure 1 above, the corrosion rate of the selected material (carbon steel) in H2-H2S service (naphtha), is predicted to be 0.601 mm/y. The predicted remaining life of the equipment is 4.99 years. The safe temperature limit for the selected material, carbon steel, at the prevailing operating H2S concentration (OC-H2S) of 0.100 mole% is 250°C, the safe hydrogen sulfide concentration limit at the prevailing operating temperature (OT) of 400°C is 0.004 mole%. S-Compass determines that this material is not resistant to sulfidation at the prevailing operating conditions and recommends 3 mitigation measures to reduce the corrosion rate to the design limit.