|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series HCl-Compass®: HCl Corrosion Modeling and Prediction High-Value Software Solutions to Costly Corrosion Version 9.23

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins |

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training

& Support |

CorrCompass |

|

|

HCl-Compass is the only device and OS independent predictive software on the market for the modeling and prediction of corrosion by aqueous hydrochloric acid and dry HCl gas. Designers, engineers, consultants, maintenance and inspection personnel can quickly assess and quantify the impact of process variables on the corrosion rate and the remaining life of piping, vessels, and other equipment handling hydrochloric acid in aqueous or gaseous phases.

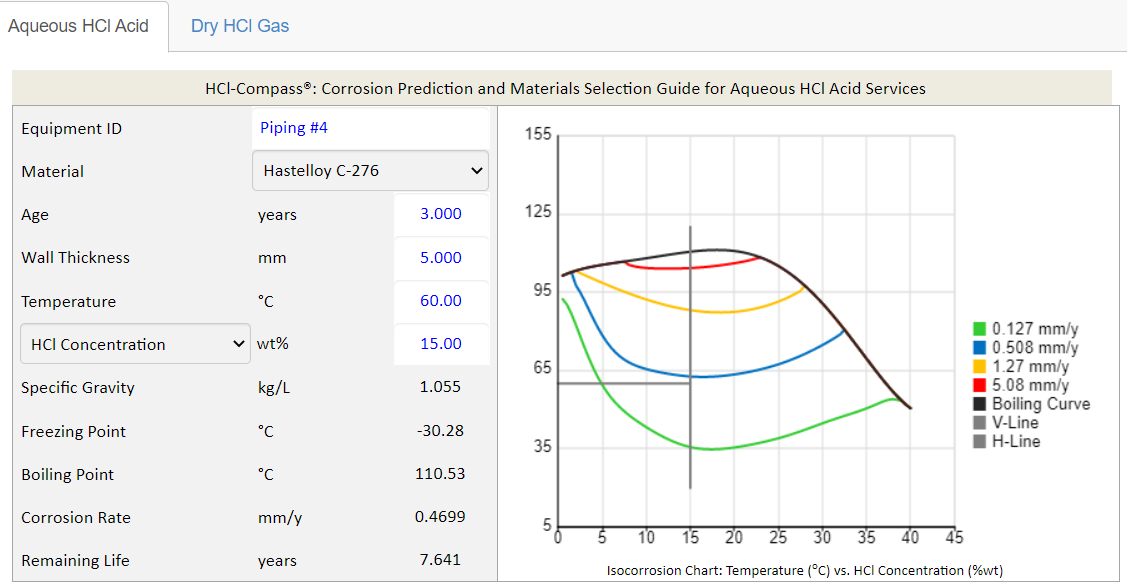

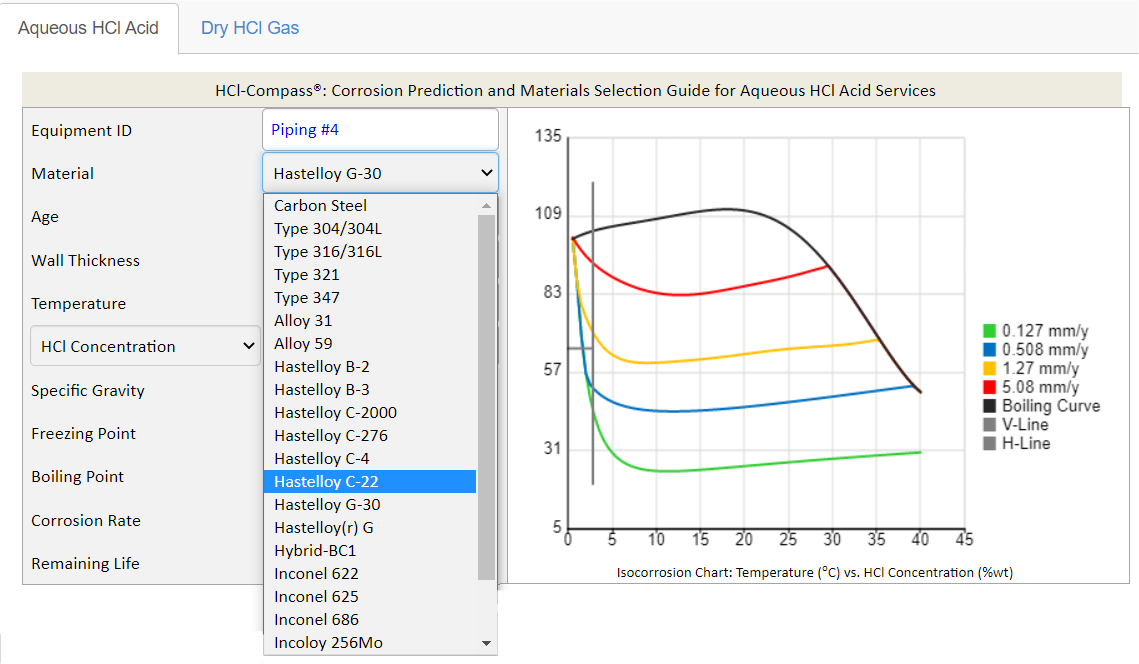

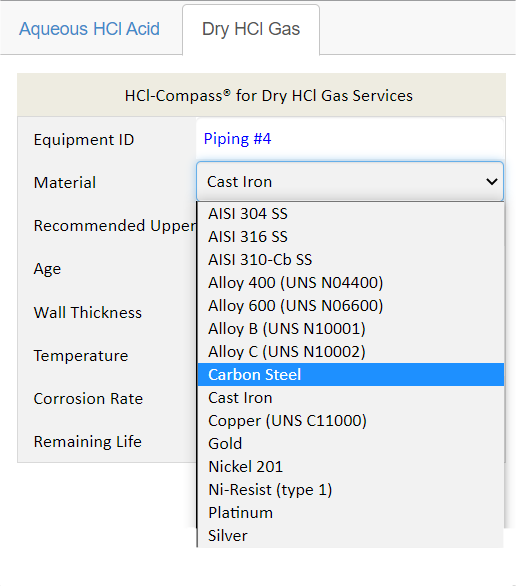

Figures below demonstrate the operation of HCl-Compass. With HCl-Compass, corrosion prediction and materials selection for hydrochloric acid services are as easy as 1-2-3. (1) Select the material from the dropdown list, (2) Enter the temperature and the concentration of hydrochloric acid (or the pH, or the chloride concentration) (3) Review the prediction results

HCl-Compass predicts the specific gravity, the freezing point, and the boiling point of the hydrochloric acid (HCl), the corrosion rate of the selected alloy at the specified temperature and concentration or pH, and the remaining life of the component. In addition to that, HCl-Compass also plots the isocorrosion diagram for the selected alloy so as to give users a complete picture of the corrosion behavior of the selected alloy across the entire ranges of the HCl acid concentration and the service temperature.

Figure 1 HCl-Compass Predicts the Corrosion Rate of Alloys in Hydrochloric Acid Corrosion Services

Figure 2 HCl-Compass Predicts HCl Corrosion and Simplifies Materials Selection for Hydrochloric Acid Services

The following corrosion resistant alloys for aqueous HCl services are

included in HCl-Compass software:

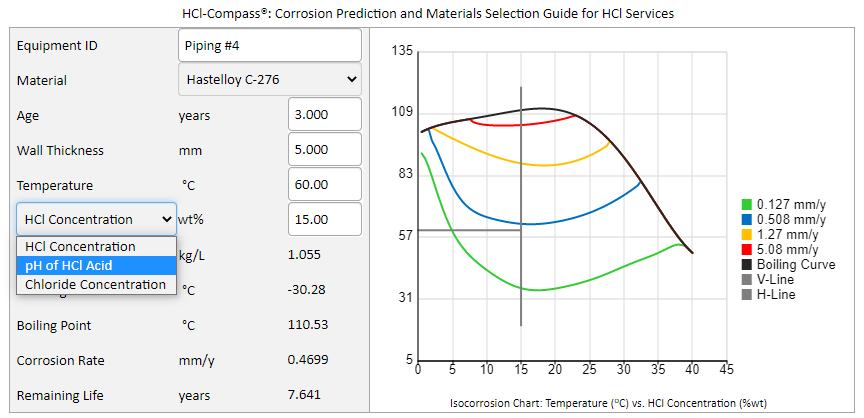

Carbon Steel For equipment and piping systems directly handling hydrochloric acid, users can use the acid concentration (wt%) as input parameter to predict the HCl corrosion rate (Figure 3). For dilute HCl condensate as is the case in

HCl transmission tubing in plants manufacturing microchips and

semiconductors and in crude distillation, hydrotreating, and catalytic reforming units

in oil refineries where HCl forms by the hydrolysis of magnesium and calcium chloride salts and results in dilute HCl in the overhead system, users can choose to use

pH or chloride concentration (in ppmw) as the input parameter to predict the HCl corrosion rate (Figures 4-5).

Figure 3 HCl-Compass Predicts and Models the Effects of HCl Concentration, or pH, or Chloride Concentration on the Corrosion Rate

Figure 4 HCl-Compass Predicts and Models the Effects of pH on HCl Corrosion

Figure 5 HCl-Compass Predicts and Models the Effects of Chloride Concentration on HCl Corrosion

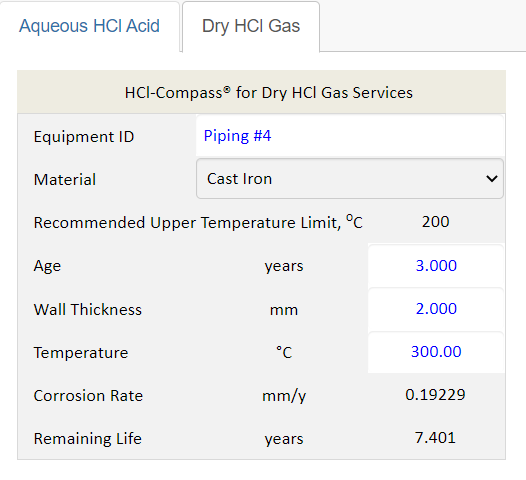

HCl-Compass also predicts corrosion by dry hydrochloric acid gas at high

temperature (Figures 6-7). The software provides a cost-effective

solution to selection of materials for piping, vessels, and other

equipment handling dry hydrochloric acid gas.

Figure 6 HCl-Compass Predicts and Models the Corrosion by Dry HCl

Gas

Figure 7 HCl-Compass Provides Software Solutions to Material Selection for Dry HCl Gas Services

The following corrosion resistant alloys for dry hydrochloric acid

services are included in the corrosion prediction software:

AISI 304 SS

The powerful applications of HCl-Compass are truly unlimited in engineering design, remaining life prediction, and materials selection for HCl services.

Click here to contact us for licensing details and experience the power of HCl-Compass. |

|

|

HCl-Compass, giving you the right directions in HCl corrosion prediction and materials selection. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. WebCorr Corrosion Consulting Services. All rights reserved. |