|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series FuelAsh-Compass®: Modeling and Life Prediction of Fuel Ash Corrosion of Boiler & Heater Tubes

The Effective Software Solutions to Fuel Ash Corrosion Version 12.4

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of FuelAsh-Compass Software for Predictive Modeling of Fuel Ash Corrosion |

|

|

Fuel ash corrosion refers to accelerated high-temperature wastage of materials that occurs when contaminants in the fuel form deposits and then melt on the metal surfaces inside fired heaters, boilers, and gas turbines. Corrosion typically occurs with fuels of waste, oil or coal that is contaminated with a combination of chlorine, sulfur, sodium, potassium, and/or vanadium.

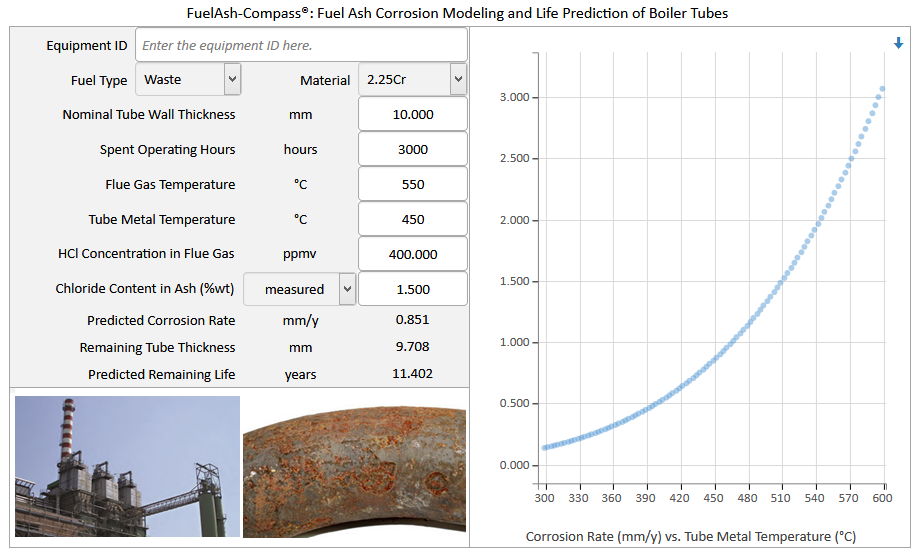

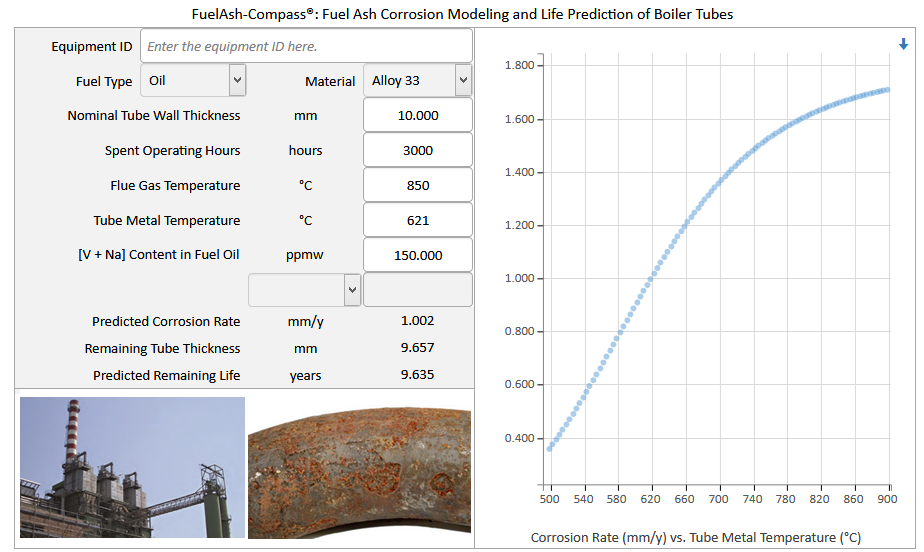

Figure 1 below shows the user interface of FuelAsh-Compass. Using FuelAsh-Compass is as easy as 1-2-3.

(1) Select the fuel type (waste, oil, coal) and the material

(2) Enter the operating conditions

(3) Review the prediction results

Figure 1 FuelAsh-Compass predicts high temperature fuel ash corrosion of fired boiler and heater tubes.

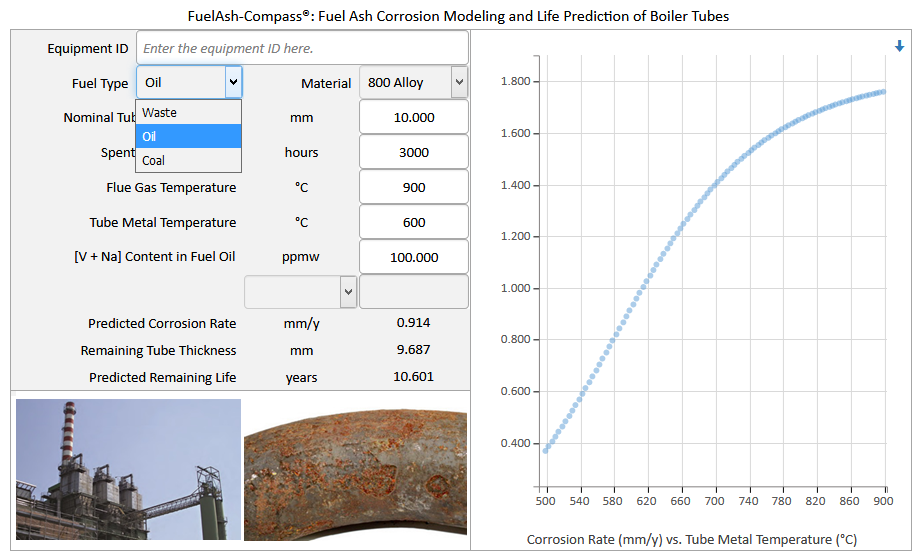

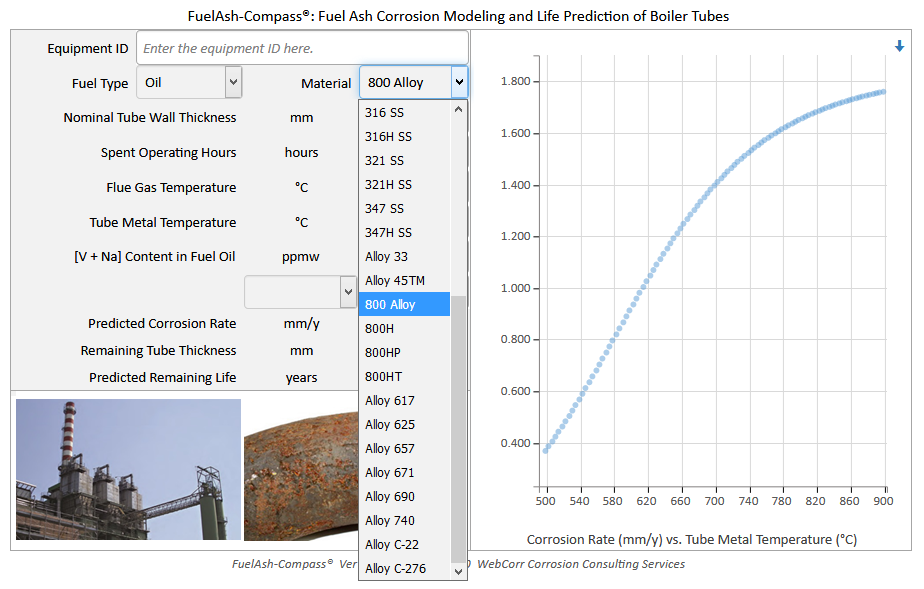

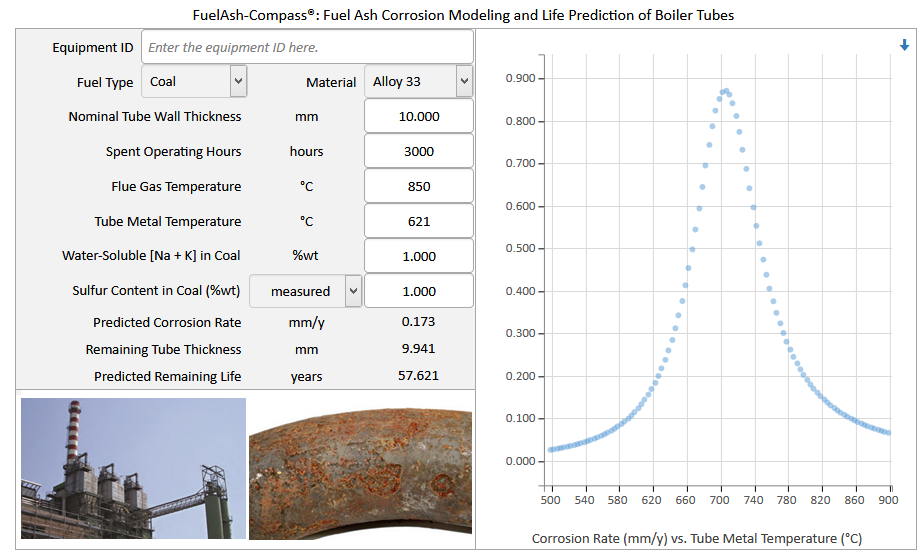

Under the prevailing operating conditions shown in Figure 1 above, the predicted corrosion rate for the 2.25Cr alloy steel is 0.851 mm/y. The remaining life is 11.402 years. The predicted corrosion rate is also plotted against the tube metal temperature. Figure 2 shows the three types of fuels available for selection in the software, namely, oil, coal, and waste. FuelAsh-Compass is a high value software tool for materials selection against ash corrosion. Figure 3 shows the alloys available for the evaluation and assessment of their resistance to ash corrosion under the specified operating condition.

Figure 2 FuelAsh-Compass models and predicts ash corrosion of three types of fuels: waste, oil, and coal.

Figure 3 FuelAsh-Compass is an effective software tool for materials selection.

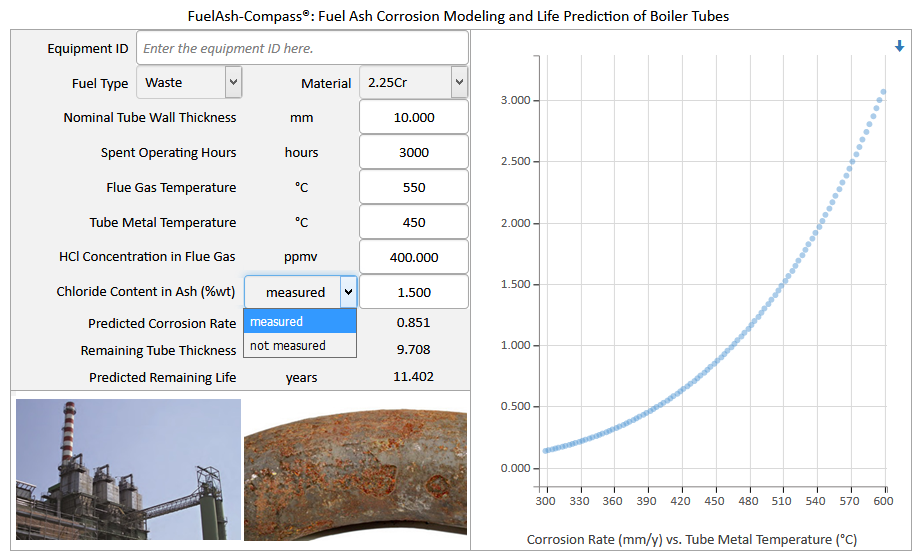

Figure 4 FuelAsh-Compass models and predicts chlorine-induced corrosion in waste-to-energy plant.

Figure 5 FuelAsh-Compass models the effects of vanadium and sodium on the oil ash corrosion rate.

Figure 6 FuelAsh-Compass models the effects of sulfur, sodium, and potassium contents in coal on the coal ash corrosion rate.

Figures 4 - 6 above show that FuelAsh-Compass models the effects of flue gas temperature, tube metal temperature, and other critical factors influencing fuel ash corrosion. The fuel and ash chemistry factors accounted for in the predictive engine of FuelAsh-Compass are:

For waste fuel: (1) concentration of HCl in flue gas; (2) chlorine concentration in ash.

For oil fuel: (1) concentrations of vanadium and (2) sodium in oil.

For coal fuel: (1) concentrations of sodium and (2) potassium in coal; (3) sulfur content in coal.

FuelAsh-Compass predicts the fuel ash corrosion rate for the following steels and alloys:

Carbon Steel

The materials database in the software is updated regularly with more alloys added to the list. If you cannot find the alloy of your interest in the list, do let us know through the Contact Us link and we will conduct the necessary work to add the alloy in the database, free of charge for licensed users of FuelAsh-Compass.

The powerful applications of FuelAsh-Compass are truly unlimited in engineering design, materials selection, process operation, inspection and maintenance, modeling and prediction of high temperature fuel ash corrosion.

Click here to contact us for licensing details and experience the power of FuelAsh-Compass. |

|

FuelAsh-Compass, giving you the right directions in the Modeling and Prediction of Fuel Ash Corrosion. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |

FuelAsh-Compass is the only device and OS independent software tool on the market for the modeling and prediction of high temperature fuel ash corrosion of boiler and heater tubes, tube hangers, and supports. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine: (1) the fuel ash corrosion rate of the selected metallurgy under the prevailing operating condition; (2) the remaining tube thickness; and (3) the remaining tube life. FuelAsh-Compass is a cloud-based software that works on any device running any OS without the need for users to install or download anything.

FuelAsh-Compass is the only device and OS independent software tool on the market for the modeling and prediction of high temperature fuel ash corrosion of boiler and heater tubes, tube hangers, and supports. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine: (1) the fuel ash corrosion rate of the selected metallurgy under the prevailing operating condition; (2) the remaining tube thickness; and (3) the remaining tube life. FuelAsh-Compass is a cloud-based software that works on any device running any OS without the need for users to install or download anything.