|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series FC-Compass®: A Software Tool for Modeling and Prediction of Fretting Corrosion The Ultimate Software Solution to Costly Corrosion Version 13.5

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training

& Support |

CorrCompass |

|

|

|

|

|

Fretting or Fretting Corrosion refers to corrosion occurring at contact areas between materials under load subjected to vibration and slip. Fretting is also called friction oxidation, wear oxidation, or chafing. Fretting corrosion is very detrimental because of the destruction of metallic components and the production of oxide debris. Seizing and galling often occur, together with loss of tolerances and loosening of mating parts. Further, fretting causes fatigue fracture since the loosening of components permits excessive strain, and the pits formed by fretting act as stress raisers. FC-Compass is the only device and OS independent software tool on the market for the modeling and prediction of fretting corrosion. Designers, engineers, architects, consultants, or maintenance and inspection personnel can quickly assess and quantify the impact of fretting corrosion on the performance and remaining life of their components or systems anytime, anywhere, on any device running any OS without the need to install or download anything (Figure 1).

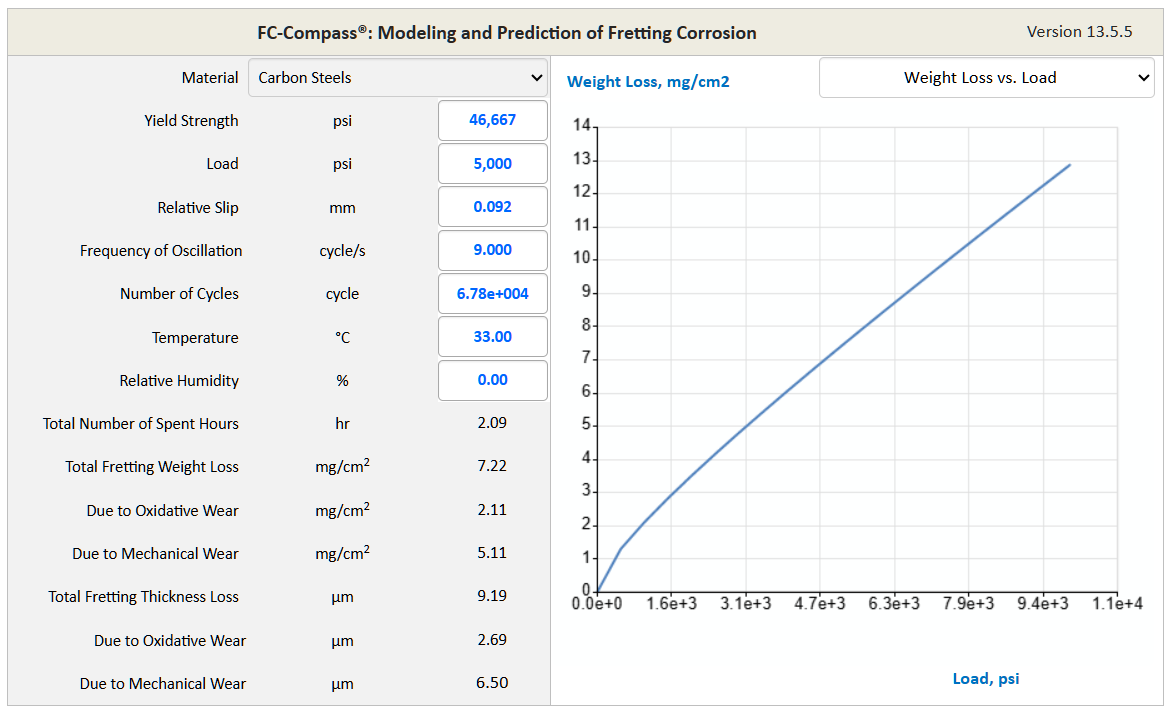

Figure 1 FC-Compass Models and Predicts Fretting Corrosion. FC-Compass models the effect of the following input parameters on the weight loss and thickness loss (Figure 1): (a) the material (b) the yield strength of the selected material (c) the contact load (d) the relative slip between the mating surfaces (e) the frequency of oscillation (f) the number of cycles (g) the temperature (h) the relative humidity

The outputs from FC-Compass include: (a) the total fretting weight loss (b) the portion of the weight loss due to oxidative wear (c) the portion of the weight loss due to mechanical wear (d) the total fretting thickness loss (e) the portion of the thickness loss due to oxidative wear (f) the portion of the thickness loss due to mechanical wear

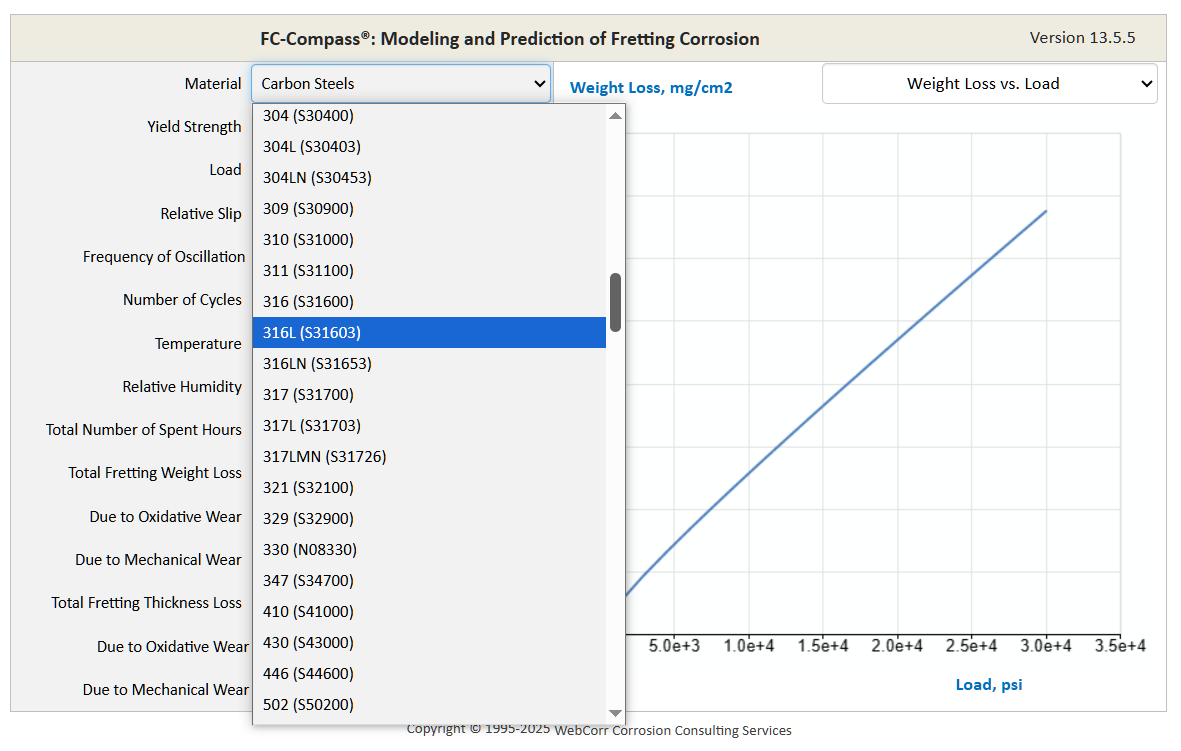

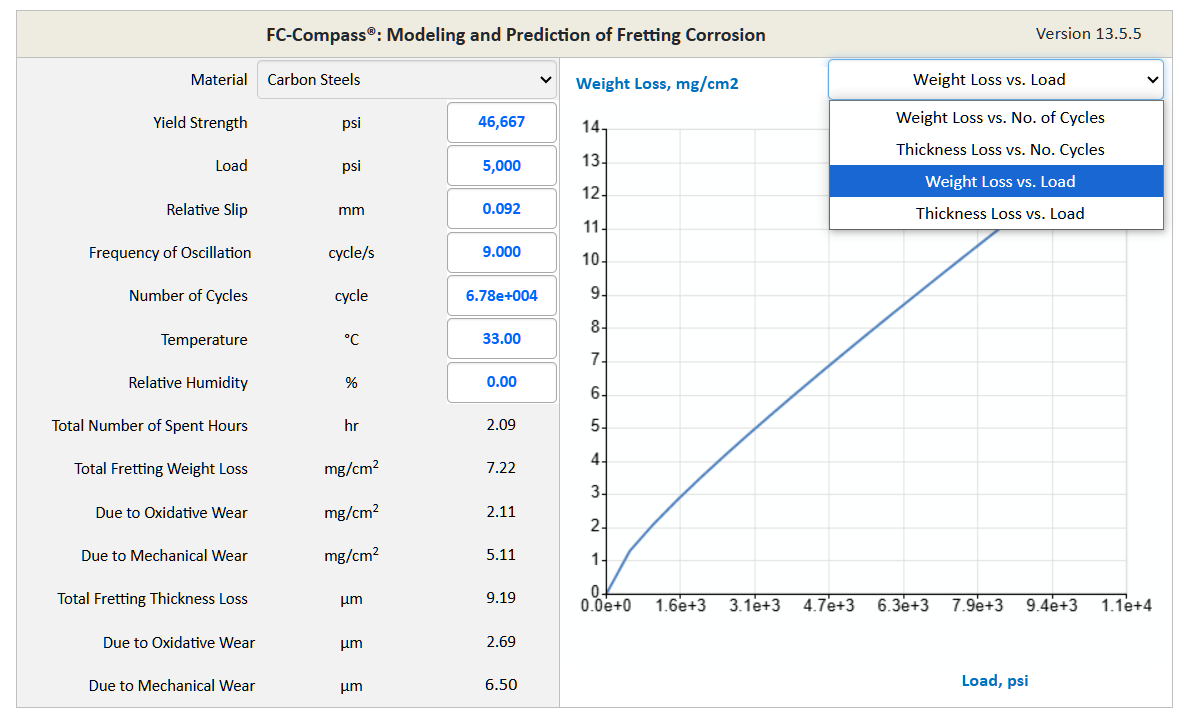

Figures 2-3 show the materials list and the plot option in the software.

Figure 2 FC-Compass Models and Predicts Fretting Corrosion of Metals and Alloys.

Figure 3 FC-Compass Predicts Fretting Corrosion with Plotting Options for the Prediction Results.

There are approximately 200 metals and alloys are included in the software:

Aluminium Alloys: If you cannot find the metal or alloy of your interest in the above list, do let us know through the Contact Us link and we will conduct the necessary research to generate the required data for inclusion in the software, free of charge for licensed users of FC-Compass.

The powerful applications of FC-Compass are truly unlimited in engineering design, fretting corrosion prediction and modeling, materials compatibility assessment, trouble-shooting process-related issues and failure analysis of components and systems.

Click here to contact us for licensing details and experience the power of FC-Compass. |

|

|

FC-Compass, giving you the right directions in Modeling and Prediction of Fretting Corrosion. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |