|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series CSR-Compass®: Modeling and Life Prediction of Creep and Stress Rupture of High Temperature Components Version 9.20

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of CSR-Compass |

|

|

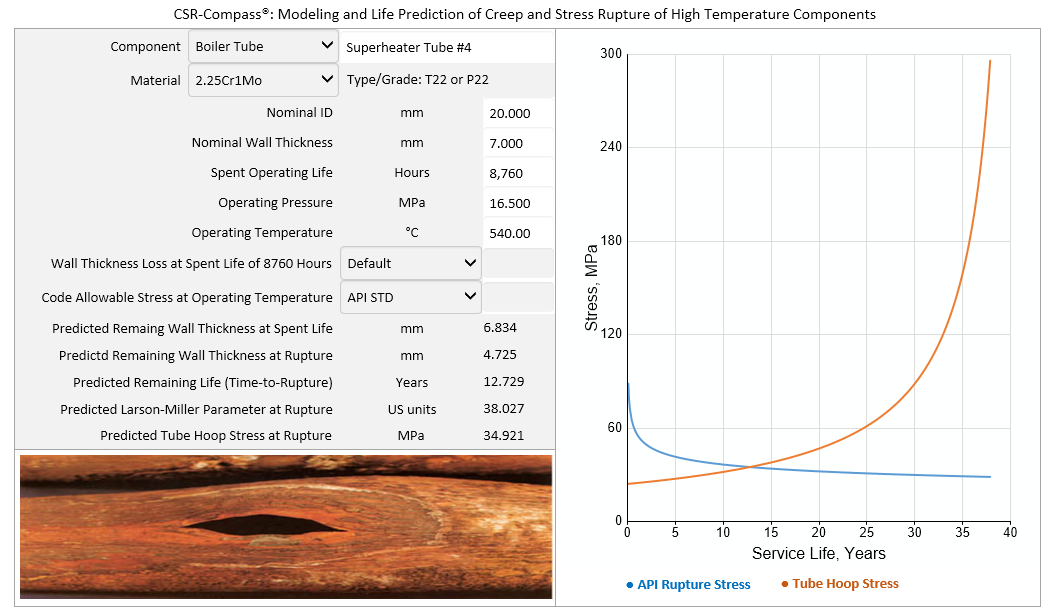

CSR-Compass is the only device and OS independent software tool on the market for the modeling and remaining life prediction of creep and stress rupture of high temperature components. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine: (1) the remaining life or the time-to-rupture under the prevailing operating temperature and pressure; (2) the remaining tube wall thickness at any specified time; (3) the predicted tube hoop stress at rupture; (4) the Larson-Miller Parameter at rupture.

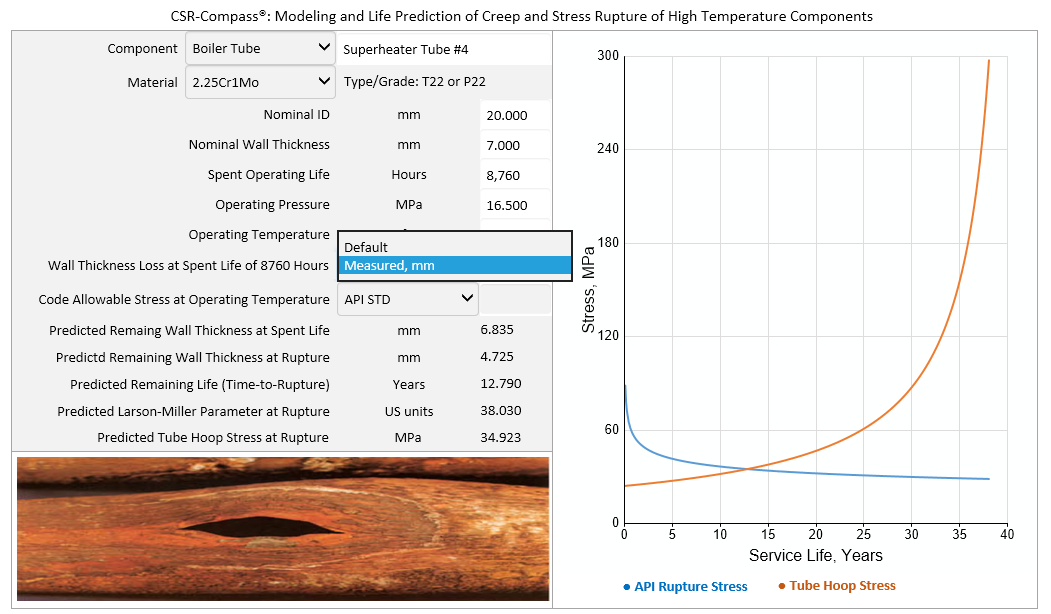

Figure 1 CSR-Compass predicts the remaining life or time-to-rupture of boiler and heater tubes due to creep damage.

Under the prevailing operating conditions shown in Figure 1 above, the predicted remaining life or time-to-rupture for the 2.25Cr1Mo (T22 or P22) tube metallurgy is 12.729 years, the predicted tube hoop stress at rupture is 34.921 MPa, the predicted tube wall thickness at rupture is 4.725 mm, and the predicted Larson-Miller Parameter at rupture is 38.027 (US units).

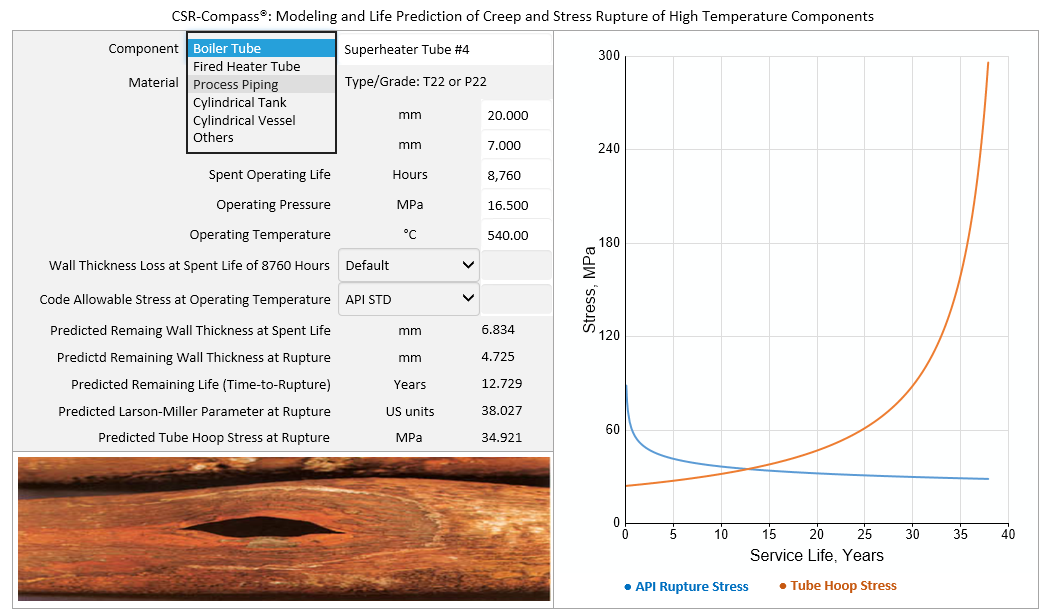

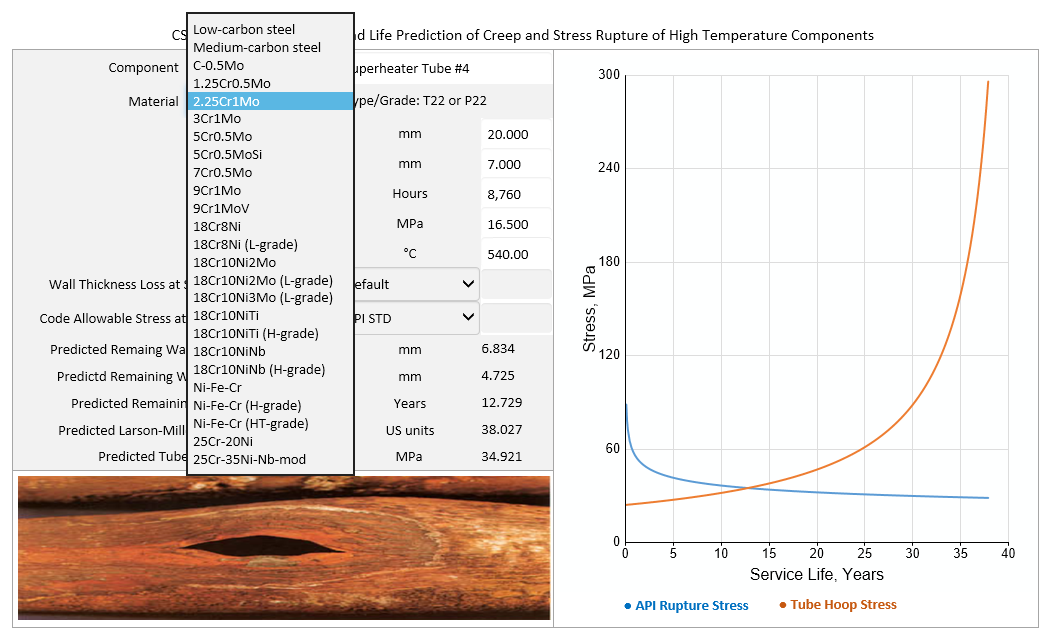

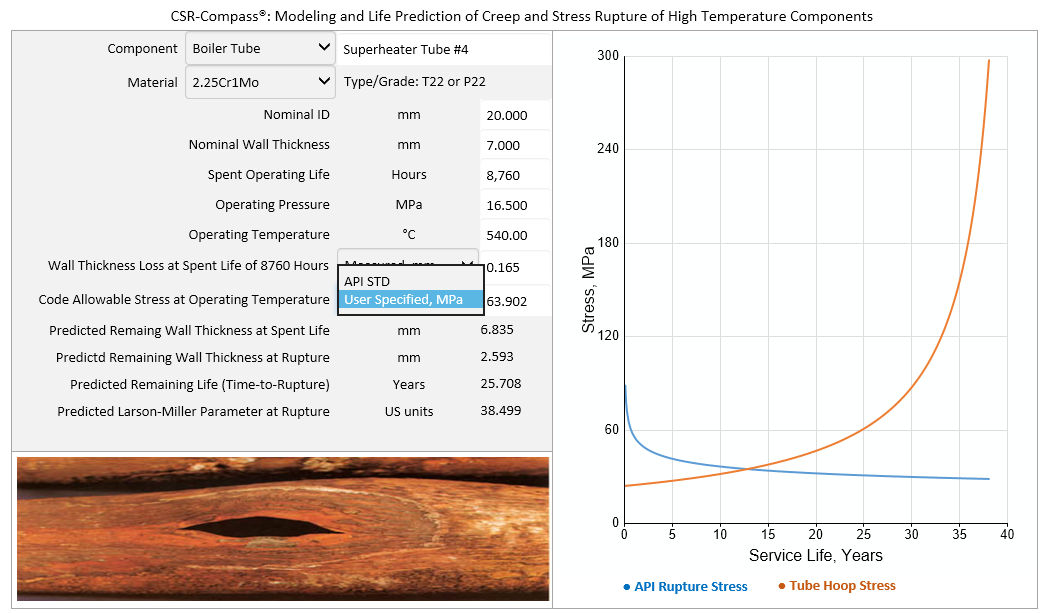

CSR-Compass is a cloud-based software that works on any device running any OS without the need for users to install or download anything. Experience the industry's first cross-platform and device-independent creep and stress rupture modeling and prediction application on your iPads, tablets, smart phones, notebooks and desktops, at any time and anywhere, in the office or in the field. No installation files to download, no browser plug-ins required, no USB dongles to carry around, and no license keys to transfer from one PC to another. CSR-Compass simply works on any device running any OS. All you need is an internet browser. Users of CSR-Compass start the modeling by selecting the high temperature component and the material from the dropdown list (Figure 2, Figure 3) and enter the operating parameters. By varying the selected material and the operating parameters, CSR-Compass can be used as a powerful software tool for material selection and process optimization.

Figure 2 CSR-Compass for modeling and life prediction of creep and stress rupture of high temperature components.

Figure 3 CSR-Compass can be used as a powerful software tool for material selection and process optimization.

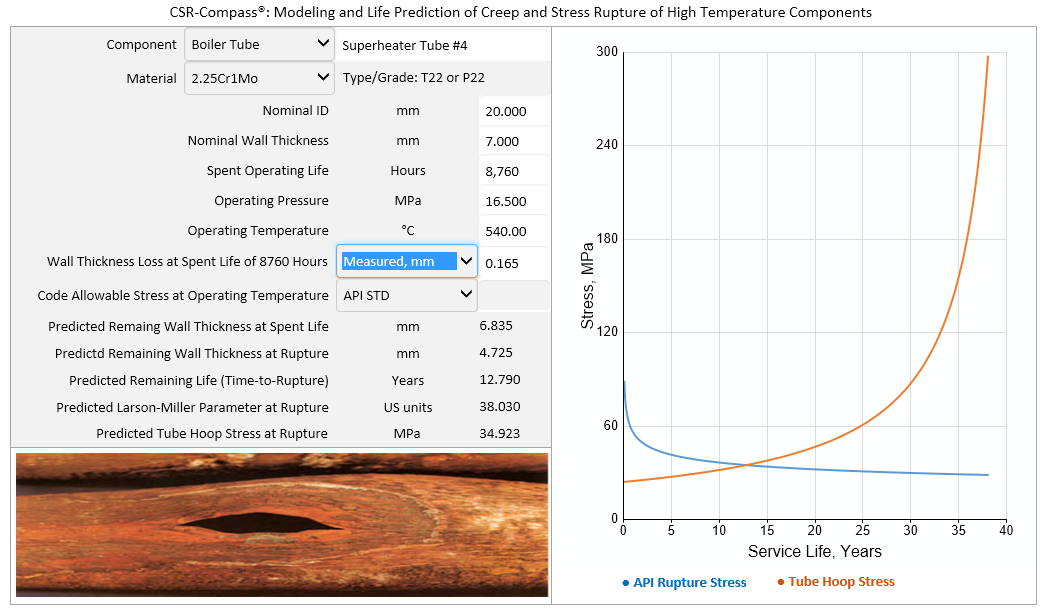

CSR-Compass models the effects of operating pressure, temperature, and wall thickness loss on the remaining life of high temperature components such as boiler and heater tubes, process piping, and pressure vessels. Users can enter the measured thickness loss over the specified operating hours if such data are available (Figure 4). If measurement data are not available, CSR-Compass utilizes the built-in predictive engine

to determine the wall thickness loss under the prevailing operating conditions (Figure 1).

Figure 4a CSR-Compass models the effects of operating pressure, temperature, and wall thickness loss on the remaining life.

Figure 4b CSR-Compass models the effect of wall thickness loss on the remaining life.

Figure 5 CSR-Compass gives users the option to use API standards or other code allowable stress for remaining life prediction.

Application Example: Remaining Life Prediction of Inconel 800 Superheater Tube

With the average operating pressure and temperature during the spent life, CSR-Compass predicts that the remaining life for the Inconel 800 superheater tube is 0.247 years (Figure 6). At certain locations, if the local temperature is raised by 15°C to 675°C, which is entirely possible, CSR-Compass predicts that the remaining life is reduced to 0.082 years.

Figure 6 Remaining Life Prediction of Creep and Stress Rupture of Inconel 800 Superheater Tube

Figure 7 Remaining Life Prediction of Creep and Stress Rupture of Inconel 800 Superheater Tube -Effect of Temperature

The powerful applications of CSR-Compass are truly unlimited in engineering design, materials selection, process operation, inspection and maintenance, corrosion risk assessment, failure analysis, modeling and prediction of creep and stress rupture of high temperature components such as boiler tubes and fire heater tubes, process piping, and pressure vessels.

Click here to contact us for licensing details and experience the power of CSR-Compass. |

|

CSR-Compass, giving you the right directions in the Modeling and Prediction of Creep and Stress Rupture |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |

Inconel

800 is in the class of high-grade austenitic steel and could withstand high temperature operation in boilers and fired heaters. Failure of the Inconel 800 tube occurred at the high temperature superheater upper bank tubes region after operating for 165,550 hours (about 19 years). The failed superheater tube was snapped into two parts and was heavily distorted and bent at several points. The tube has outer diameter of 57.1 mm and thickness of 6.8 mm. Average operating pressure was 13.8 MPa and average operating temperature was 650°C. A detailed failure analysis of the failed tube was published in the journal of Engineering Failure Analysis Vol.17 (2010) 328–333.

Inconel

800 is in the class of high-grade austenitic steel and could withstand high temperature operation in boilers and fired heaters. Failure of the Inconel 800 tube occurred at the high temperature superheater upper bank tubes region after operating for 165,550 hours (about 19 years). The failed superheater tube was snapped into two parts and was heavily distorted and bent at several points. The tube has outer diameter of 57.1 mm and thickness of 6.8 mm. Average operating pressure was 13.8 MPa and average operating temperature was 650°C. A detailed failure analysis of the failed tube was published in the journal of Engineering Failure Analysis Vol.17 (2010) 328–333.