|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series CRA-Compass®: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys Determining the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and SCC Version 12.4

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training

& Support |

CorrCompass |

|

|

Overview of CRA-Compass CRA-Compass models and predicts the threshold temperature and chloride concentration for pitting, crevice corrosion, and stress corrosion cracking (SCC) of 70 common corrosion resistant alloys used in water systems including natural seawater, chlorinated seawater, brines, produced water, formation water, brackish water, groundwater, fresh water, and potable water. Users can define their own alloys for CRA-Compass to evaluate the application limits for their resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) under the specified operating conditions. The performance of the CRAs in coastal/marine atmosphere is also included in this software.

Figure 1 below shows the alloy list in the software. Users simply select one of the 70 corrosion resistant alloys from the list or define their own alloy by entering the chemical compositions.

Figure 1 Overview of the CRA-Compass

After selecting or defining the alloy, the stacking fault energy (SFE) for the selected alloy and the pitting resistance equivalent number, PREN, as defined in the International Standard ISO 15156, are calculated and displayed for the selected alloy. The stacking fault energy is an indicator of the alloy's resistance to stress corrosion cracking (SCC). Alloys with low stacking fault energy are more prone to SCC. The pitting resistance equivalent number (PREN) is an indicator of the alloy's resistance to pitting and crevice corrosion. Alloys with low PREN are more prone to pitting and crevice corrosion.

The next step the user needs to do is to select one of the two input parameters, the temperature or the concentration of chloride, both are critical process parameters in many industries. If the user select the temperature as the input parameter (Figure 2), CRA-Compass will determine the threshold concentration of chloride for the selected alloy in terms of its resistance to pitting and crevice corrosion for both the plate and weld. The probability of stress corrosion cracking (SCC) and the temperature limit for SCC are also determined. In the application example in Figure 2, for the austenitic stainless steel (AISI Type 347),

the stacking fault energy at the specified temperature of 65oC

is 24.112 mJ/m2, the PREN is 18 (note that "super"-duplex refers to those with PREN of 40 and above). At the operating temperature of 65°C, the maximum concentration of chloride (for the steel's resistance to pitting and crevice corrosion) is 1,796 ppm

and 1,202 ppm respectively, in non-chlorinated waters and 158 ppm and 42 ppm in chlorinated waters.

The critical gap size for crevice corrosion is 0.892 µm. The open circuit potential, the critical pitting potential, and the repassivation potential are -74 mV, 86 mV, and -357 mV respectively. The probability of chloride stress corrosion cracking is 98.37% when the temperature exceeds 53oC at a chloride concentration of 1,796 ppm in non-chlorinated waters. The SCC crack growth rate after initiation is 40.174 um/day or 14.663 mm/y. The crevice corrosion

propagation rate in natural seawater is 337 µm/y and the crevice

incubation period is 1 day. The maximum pit depth is 205 µm after 4 years exposure in coastal/marine atmosphere. The

degree of surface rust and stains are rated in accordance with BS ISO

23721 standard, with a RN number of 2 and a rust surface area ratio of 47%.

If the user select the chloride concentration as the input parameter, CRA-Compass will determine the threshold temperature for the selected alloy (Figure 3) in both chlorinated and non-chlorinated waters in terms of its resistance to pitting and crevice corrosion. The probability of stress corrosion cracking (SCC) and the temperature limit for SCC are also determined. If an alloy is susceptible to SCC and the operating temperature is above the threshold temperature, CRA-Compass will predict the crack growth rate of SCC for the selected alloy. The open circuit potential, the critical pitting potential, and the repassivation potential for the selected alloy are computed by CRA-Compass and are displayed under the Output on Threshold Temperature and Chloride Concentration. This predicted values correspond to the measurements in 3.5% NaCl solution at 27°C in the laboratory.

Figure 2

Figure 3

If an alloy is not in the built-in list, the user can select "User-Defined-Alloy" from the list and then enter the chemical compositions in the table as shown in Figure 4 below. The PREN number and all other predictions are then computed accordingly.

Figure 4 User-Defined-Alloy

Three performance indicators for the selected alloy in the coastal/marine atmosphere are predicted based on the results from 4 years field exposure: (1) the maximum depth of corrosion attack; (2) the form of corrosion (pitting, uniform corrosion, no corrosion); (3) the

degree of rust and stains as per BS ISO 23721 standard.

Figures 5a and 5b below show that CRA-Compass models and predict threshold temperature and chloride concentration for both the plate and the weld of CRAs.

Figure 5a CRA Materials Selection - Comparing the Pitting Resistance of Plate vs Weld

Figure 5b CRA Materials Selection - Comparing the Crevice Corrosion Resistance of Plate vs Weld

List of Alloys Available in CRA-Compass

Type 410

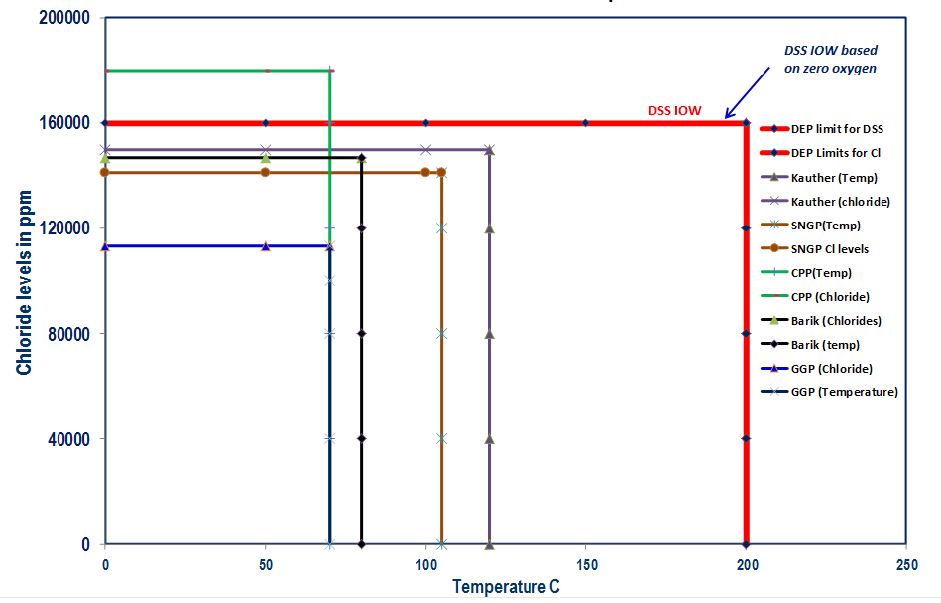

Use of CRA-Compass to Establish Integrity Operating Windows in a Gas Processing Plant

Integrity operating windows are established limits for process variables (parameters) that can affect the integrity of the equipment if the process operation deviates from the established limits for a pre-determined length of time (includes critical, standard and informational IOWs). CRA-Compass is a powerful software tool that can help asset owners and operators quickly and accurately determine the IOW limits. CRA-Compass can be used to determine the temperature and chloride IOW limits for a duplex stainless steel used in a gas processing plant.

Figure 5c CRA-Compass Software for Determining Integrity Operating Windows (IOWs)

The powerful applications of CRA-Compass are truly unlimited in engineering design, materials selection, process operation, inspection and maintenance, corrosion risk assessment, setting the IOW limits, corrosion modeling and remaining life prediction.

Click here to contact us for licensing details and experience the power of CRA-Compass. |

|

|

CRA-Compass, giving you the right directions in CRA selection and application. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2025. WebCorr Corrosion Consulting Services. All rights reserved. |