|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series CUI-Compass®: A Software Tool for the Prediction and Assessment of Corrosion Under Insulation and Fireproofing Software Solutions to Industrial Corrosion

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins |

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of CUI-Compass |

|

|

CUI-Compass is the only device and OS independent software tool on the market for the prediction and assessment of corrosion under insulation and fireproofing (CUI and CUF). Designers, engineers, architects, consultants, maintenance and inspection personnel can quickly assess and quantify the CUI and CUF likelihood ratings and risk rankings of their components or systems, anytime, anywhere, on any device running any OS without the need to install or download anything. CUI-Compass also predicts external chloride stress corrosion cracking, or ECSCC, and the temperature and chloride application limits for stainless steels and alloys.

CUI-Compass has 3 modules under the CUI, ECSCC, and CUF tabs. The CUI module is for the prediction and assessment of corrosion under insulation for carbon and low alloy steels, austenitic and duplex stainless steels. The ECSCC module is for the prediction and assessment of external chloride stress corrosion cracking (ECSCC), maximum pit depth, the temperature limit, and the chloride concentration limit for stainless steels and alloys. The CUF module is for the the prediction and assessment of corrosion under fireproofing. Figures below show the screen shots of CUI-Compass.

Figure 1 CUI-Compass Predicts the CUI Likelihood Rating and CUI Risk Ranking.

Prediction and Assessment of Corrosion Under Insulation for Carbon and Low Alloy Steels, Austenitic and Duplex Stainless Steels CUI-Compass models the effects of the following 7 parameters on the likelihood and risk of corrosion under insulation for carbon and low alloy steels, austenitic and duplex stainless steels: (1) Temperature (2) Coating condition and age (3) Jacketing and insulation condition (4) Heat tracing (5) External environment (6) Insulation type (7) Line size or nozzle size Users of CUI-Compass simply select the parameters from the dropdown list. CUI-Compass makes an overall assessment of the contributing factors to corrosion under insulation and computes the CUI likelihood rating and CUI risk ranking in compliance with the latest edition of API RP 583. The CUI likelihood rating and the CUI risk ranking can be used in Risk-Based Inspection (RBI) assessment (API 580, API 581) and Fitness-For-Service Assessments (API 579-1 / ASME FFS-1). CUI-Compass can also be used for materials evaluation and selection. Figure 1 shows the CUI performance difference between carbon/low alloy steels and austenitic/duplex stainless steels under similar conditions.

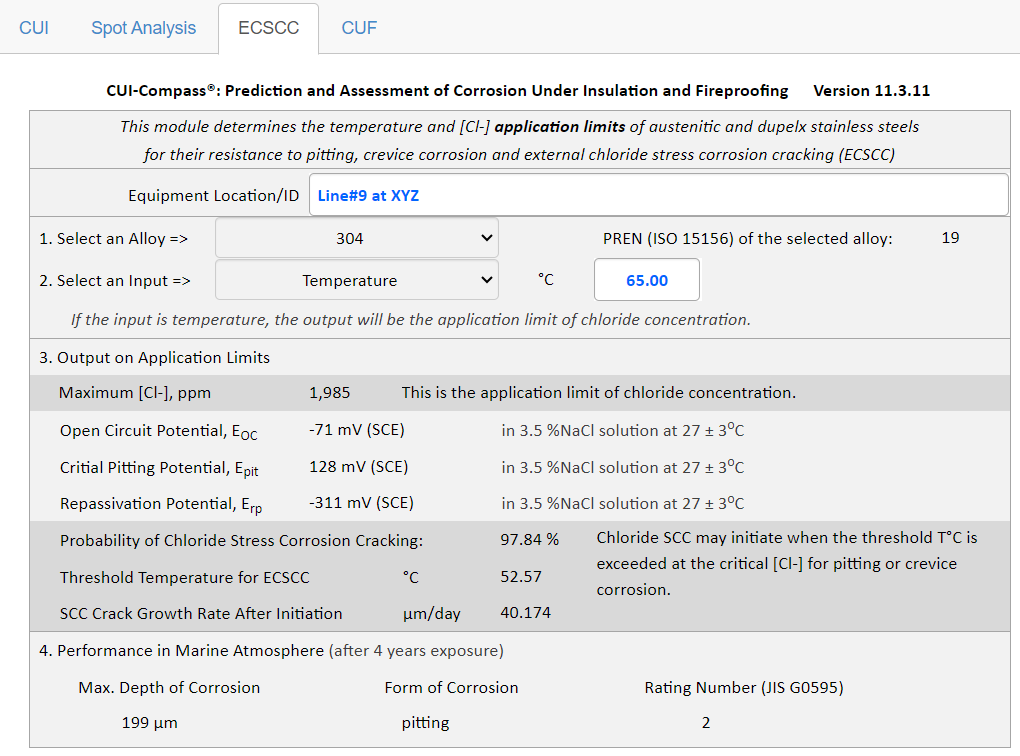

Prediction and Assessment of External Chloride Stress Corrosion Cracking (ECSCC) Under the ECSCC tab, CUI-Compass models the effects of temperature and chloride concentration on the probability of external chloride stress corrosion cracking (ECSCC) and resistance to localized corrosion such as pitting and crevice corrosion. The outputs from CUI-Compass includes the following (Figure 2): (1) The pitting index (PREN) of selected alloy in accordance with ISO 15156 (2) The maximum temperature for resistance to localized corrosion such as pitting corrosion and crevice corrosion (when the user input is chloride concentration) (3) The maximum chloride concentration (when the user input is temperature) (4) The predicted open circuit potential of the selected alloy (5) The critical pitting potential of the selected alloy (6) The repassivation potential of the selected alloy (7) The probability of chloride stress corrosion cracking when the maximum temperature is exceeded. (8) The maximum pit depth (9) The rust rating number based on JIS G0595

Figure 2 CUI-Compass Predicts External Chloride Stress Corrosion Cracking (ECSCC), Temperature and Chloride Application Limits.

Prediction and Assessment of Corrosion Under Fireproofing (CUF) The CUF module is for the the prediction and assessment of corrosion under fireproofing. CUI-Compass models the effects of the following 6 parameters on the likelihood and risk of corrosion under fireproofing (CUF): (1) Temperature (2) Coating condition and age (3) Fireproofing condition (4) Potential for water ingress (5) External environment (6) Materials type

Users of CUI-Compass simply select the parameters from the dropdown list (Figure 3). CUI-Compass makes an overall assessment of the contributing factors to corrosion under fireproofing (CUF) and computes the CUF likelihood rating and CUF risk ranking in compliance with the latest edition of API RP 583. The CUF likelihood rating and the CUF risk ranking can be used in Risk-Based Inspection (RBI) assessment (API 580, API 581) and Fitness-For-Service Assessments (API 579-1 / ASME FFS-1).

Figure 3 CUI-Compass Predicts the CUF Likelihood Rating and CUF Risk Ranking.

The powerful applications of CUI-Compass are truly unlimited in engineering design, CUI-CUF prediction and risk assessment, materials selection, RBI inspection and RBI assessment, trouble-shooting process-related issues and failure analysis of components and systems. |

|

CUI-Compass, giving you the right directions in CUI-CUF Prediction and Risk Assessment |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |