|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series ABC-Compass®: Ammonium Bisulfide Corrosion Modeling and Life Prediction

The Ultimate Software Solutions to Ammonium Bisulfide Corrosion

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of ABC-Compass |

|

|

Ammonium bisulfide corrosion, also called alkaline sour water corrosion, refers to corrosion occurring in hydroprocessing reactor effluent streams and in units handling alkaline sour water, particularly in areas of high turbulence. In hydroprocessing reactors, nitrogen in the feed is converted to ammonia (NH3) and reacts with hydrogen sulfide (H2S) to form ammonium bisulfide (NH4HS). NH4HS precipitates out of the gas phase in the reactor effluent stream and may cause fouling and plugging unless flushed away with wash water. A similar reaction between NH3 and H2S occurs in FCC and coker units, leading to precipitation in the associated fractionator overheads. NH4HS salt deposits can lead to under-deposit corrosion and fouling. ABC-Compass is the only device and OS independent software tool on the market for the modeling and life prediction of ammonium bisulfide corrosion of reactor effluent air coolers (REACS) and associated piping. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine: (1) the ammonium bisulfide corrosion rate under the prevailing operating condition; (2) the remaining life of the component; (3) the probability of chloride stress corrosion cracking; (4) the threshold temperature and the threshold chloride concentration for SCC; (5) the crack growth rate after SCC initiation; and (6) the isocorrosion curves for carbon steels.

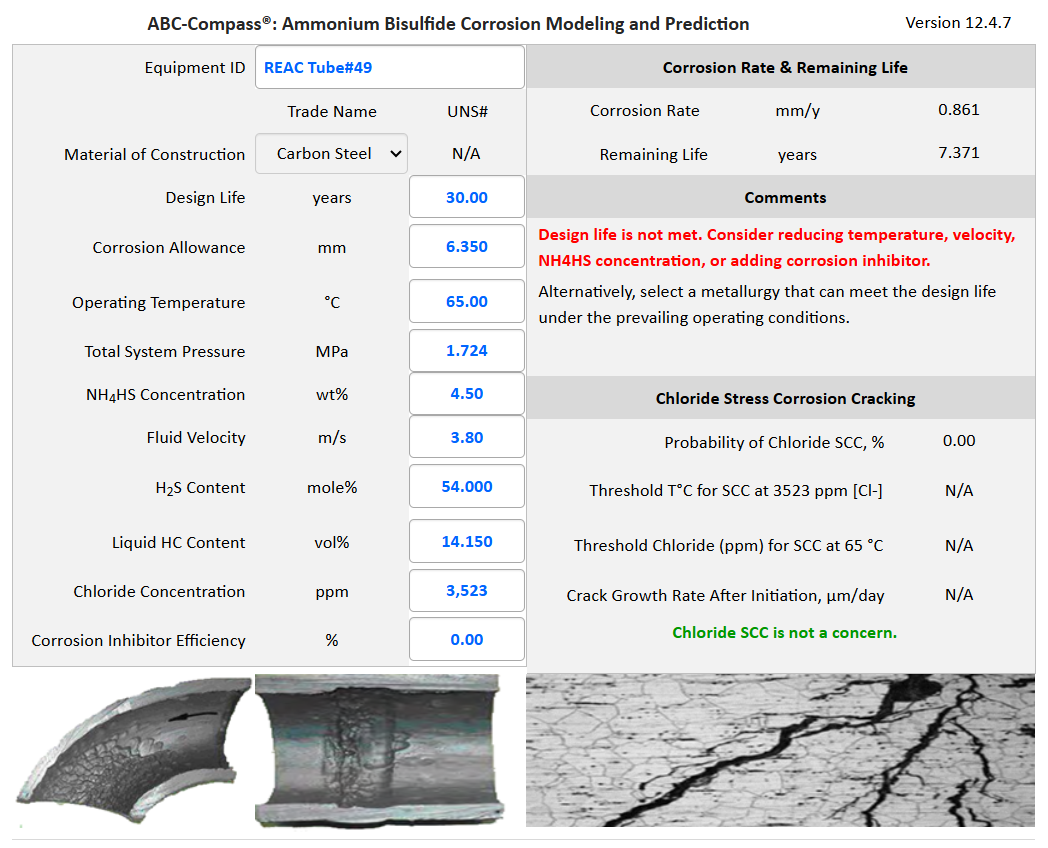

Figure 1 ABC-Compass, the only device and OS independent software tool on the market for modeling and prediction of ammonium bisulfide corrosion and stress corrosion cracking.

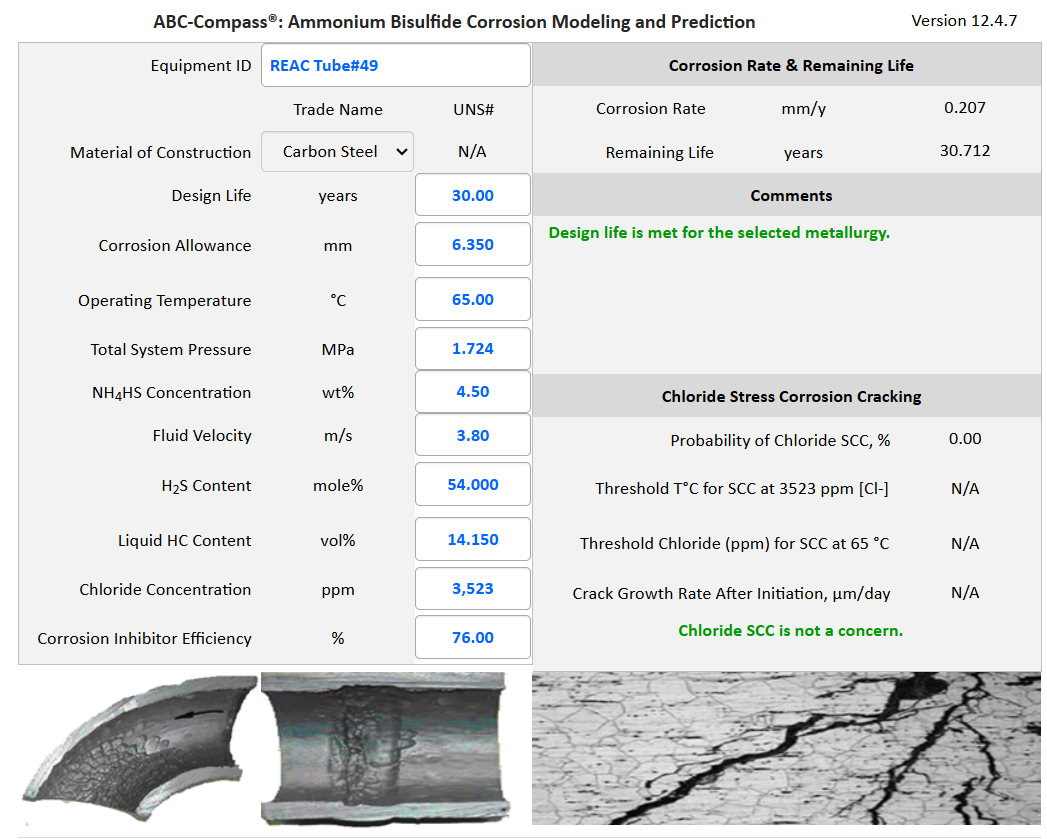

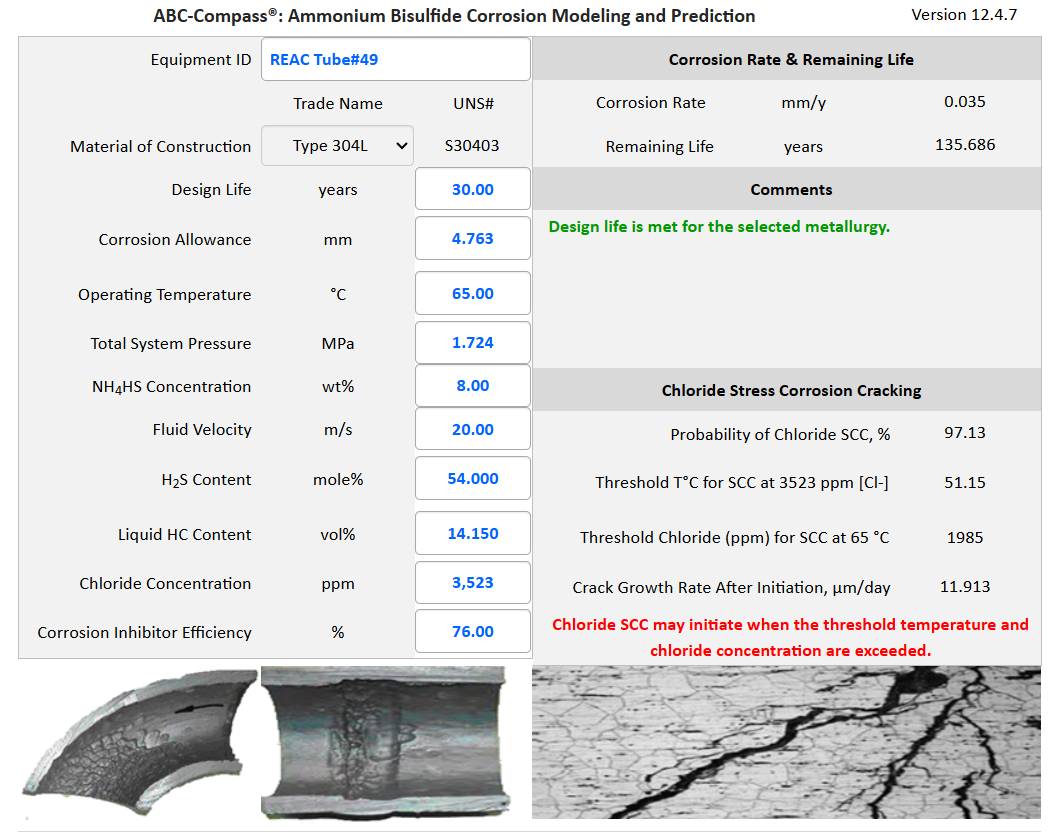

Under the prevailing operating conditions shown in Figure 1 above, the predicted ammonium bisulfide corrosion rate for carbon steel is 0.861 mm/y, the predicted remaining life is 7.371 years. ABC-Compass predicts that the design life of 30 years cannot be met with the selected carbon steel metallurgy. The presence of free cyanide in the system may cause hydrogen blistering (HB), hydrogen induced cracking (HIC), and stress-oriented hydrogen induced cracking (SOHIC). ABC-Compass recommends the following options to reduce the ammonium bisulfide corrosion rate to a level that can meet the design life of 30 years: (1) reducing the operating temperature; (2) reducing the fluid velocity; (3) reducing the concentrations of NH4HS/H2S/CN; (4) adding a corrosion inhibitor; (5) upgrading the metallurgy. ABC-Compass predicts (Figure 2) that a corrosion inhibitor with an efficiency of 76% can reduce the ammonium bisulfide corrosion rate to 0.207 mm/y and thus meeting the design life of 30 years. Alternatively, an upgrade to stainless steel type 304L can meet the design life at higher concentration of NH4HS and higher velocity of 20 m/s, as shown in Figure 3. These results have demonstrated that ABC-Compass is a highly effective and highly versatile software tool not only for ammonium bisulfide corrosion prediction but also for materials selection, corrosion inhibitor evaluation, and process optimization in the refining and petrochemical industry.

Figure 2 ABC-Compass, the highly effective software tool for material selection, corrosion inhibitor evaluation, and process optimization.

ABC-Compass is a cloud-based software that works on any device running any OS without the need for users to install or download anything. Experience the industry's first cross-platform and device-independent ammonium bisulfide corrosion modeling and prediction app on your iPads, tablets, smart phones, notebooks and desktops, at any time and anywhere, in the office or in the field. No installation files to download, no browser plug-ins required, no USB dongles to carry around, and no license keys to transfer from one PC to another. ABC-Compass simply works on any device running any OS. All you need is an internet browser.

Figure 3 ABC-Compass, the only device and OS independent software tool on the market that can predict the threshold temperature and threshold chloride concentration for stress corrosion cracking (SCC) and the crack growth rate after SCC initiation.

ABC-Compass models the effects of critical factors such as ammonium bisulfide concentration, temperature, fluid velocity, hydrocarbon content, H2S partial pressure,

free cyanide, and chloride on the corrosion rate, chloride stress corrosion cracking (SCC),

hydrogen blistering, and hydrogen-induced cracking. By varying the selected material and the operating parameters, ABC-Compass can be used as a highly effective software tool for material selection and process optimization. Integrity operating windows (IOWs) can also be easily established for the selected material. In Figure 3 above, ABC-Compass predicts that the probability of chloride stress corrosion cracking for 304L under the prevailing operating conditions is 97.13%, the threshold temperature at the specified chloride concentration of 3523 ppm for SCC is 51.15°C, the threshold chloride concentration at the specified operating temperature of 65°C is 1985 ppm. Both the threshold temperature and the threshold chloride concentration for SCC are exceeded under the prevailing operating conditions, ABC-Compass predicts that SCC may initiate and the crack growth rate after initiation is 11.913

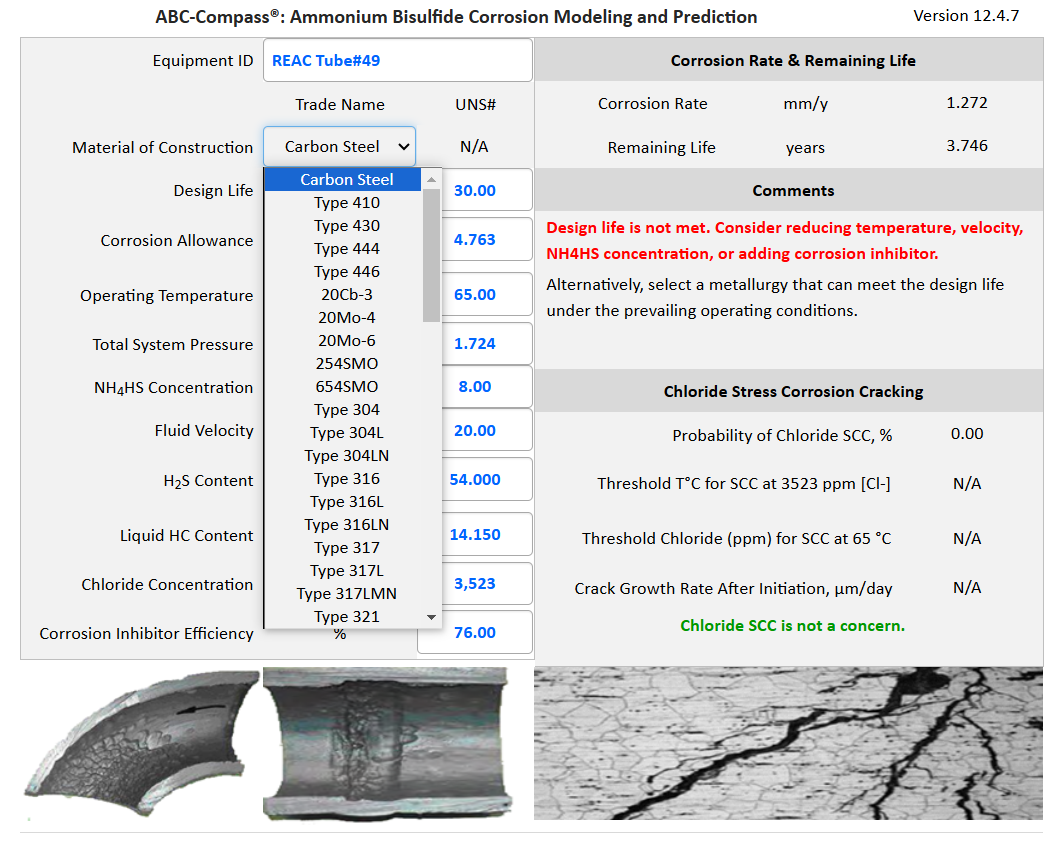

Figure 4 ABC-Compass predicts ammonium bisulfide corrosion and chloride concentration for stress corrosion cracking (SCC) for carbon steels and more than 60 alloys.

Using ABC-Compass is as easy as 1-2-3.

(1) Select the material from the dropdown list and enter the design data

(Figure 4)

(2) Enter the process data

(3) Review the prediction results

ABC-Compass has more than 60 steels and alloys in the software database

for you to choose from. If you cannot find the material of your interest

in the list below, contact us and we will conduct the necessary research and add that material to the selection list, free of charge for licensed users.

Metals and Alloys included in ABC-Compass software database:

Carbon Steel

The powerful applications of ABC-Compass are truly unlimited in engineering design, materials selection, corrosion inhibitor evaluation, process optimization, inspection, predictive maintenance, corrosion risk assessment, modeling and prediction of ammonium bisulfide corrosion and chloride stress corrosion cracking (SCC) of reactor effluent air coolers (REACS) and associated piping.

Click here to contact us for licensing details and experience the power of ABC-Compass. |

|

ABC-Compass, giving you the right directions in the Modeling and Prediction of Ammonium Bisulfide Corrosion and Chloride SCC. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2026. All rights reserved. |