|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | ||

|

Microbiologically Influenced Corrosion (MIC): -Recognition, Mitigation and Prevention |

||

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List | Why WebCorr |

||

| MIC Corrosion Course Overview | ||

|

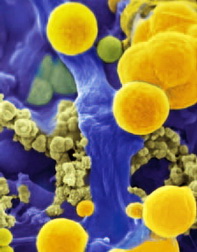

Microbiologically influenced corrosion (MIC), also known as microbial corrosion or biological corrosion, is the deterioration of metals as a result of the metabolic activity of microorganisms. Many industries are known to be affected by MIC. This 5-day corrosion course aims to provide the participant with a thorough understanding of the causes of microbiologically influenced corrosion, its recognition, treatment, mitigation, testing and monitoring, and prevention. Upon completion of this corrosion short course the participants will be able to identify the different forms of corrosion damage caused by different types of bacteria, apply appropriate strategies and methods to treat and mitigate systems affected by MIC. Guidelines for the prevention of microbiologically influenced corrosion are also included in the course material.

|

||

|

||

| MIC Corrosion Course Outline | ||

|

1. Introduction to Corrosion

2. Introduction to

Microbiologically Influenced Corrosion

(MIC)

2.3 Flesh-eating bacteria affecting human beings vs metal-eating bacteria affecting materials 2.4 MIC in action: accelerated low water corrosion (ALWC)

3.

Different Types of Bacteria Known to Cause Microbiologically Influenced

Corrosion

3.2 Common

Microorganisms Associated with MIC

5. Environments Where MIC-Causing Bacteria Exist 6. Industries and Systems Affected by Microbiologically Influenced Corrosion (MIC)

7. Environmental Chemistry Conducive to MIC

8. Common Metals and Alloys Affected by MIC: Case Studies 8.1 Cast Irons, Carbon Steels and Low Alloy Steels 8.2 Stainless Steels and Alloys 8.3 Nickel and Nickel Alloys 8.4 Copper and Copper Alloys 8.5 Aluminium and Aluminum Alloys 8.6 Zinc and Zinc Alloys

9. The Damaging Effects of MIC on Metals and Alloys 9.1 Accelerated General Corrosion 9.2 Rapid Through Wall Pitting or Perforation 9.3 Tubercle Formation

10. How to Recognize Microbiologically Influenced Corrosion (MIC) 10.1 Areas and Surfaces Known to be Susceptible to MIC 10.2 Visual Characteristics of MIC 10.3 Location and Distribution Patterns of MIC

10.4 Characteristic

Features of MIC Under the Microscope 11.1 Field Testing of MIC 11.2 Laboratory Testing of MIC 11.3 Online Monitoring of MIC

12. Treatment, Mitigation and Prevention of Microbiologically Influenced Corrosion (MIC)

|

||

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List |

||

| Who Should Attend This MIC Corrosion Course | ||

|

Many industries and systems are known to be affected by MIC. This corrosion short course will benefit corrosion practitioners, designers, architects, technical managers, inspection and maintenance engineers, quality control personnel, facility owners and operators, and those involved in failure analysis.

Successful completion of this corrosion course helps participants prepare for their NACE certification examinations at the Corrosion Technician, Corrosion Technologist and Senior Corrosion Technologist levels.

|

||

| Registration for This Corrosion Course | ||

|

Click here to register for this corrosion course online, or Click here to download this corrosion course brochure with registration form in PDF format.

|

||

| In-House Training Corrosion Courses | ||

|

There is no limit to the number of participants required for in-house training corrosion courses. We conduct the in-house training corrosion course at your company's premises worldwide, and at a time convenient to your company.

Click here to contact us for a quotation for in-house training corrosion courses. |

||

| Corrosion Course-On-Demand | ||

|

Click here to contact us for a quotation. |

||

| Online Corrosion Courses and Distance Learning Corrosion Courses | ||

|

Click here to to register an online corrosion short course. |

||

| PowerPoint Slides and Test Banks for Trainers, Instructors, Tutors, University Lecturers and Professors | ||

|

If you are involved in teaching or training, you may wish to purchase a complete set of the trainer's package for this training course. The trainer's package comes complete with ready-to-use PowerPoint slides (fully editable) and test bank (with answer keys). These ready-to-use PowerPoint slides contain high quality color photographs, illustrations, animations, audio and video clips. The test bank contains questions in four categories: (1) true or false, (2) multiple choice, (3) calculation, and (4) reasoning and open-ended discussions. The trainer's package is suitable for in-house training and university teaching. This is exactly the same package that WebCorr uses to deliver our current training course. The one-time lump sum fee allows your organization to use the training package and also modify it. For example, your organization may modify the course contents and re-name/re-brand the course under your organizationís name. WebCorr only retains the copyright of the original PowerPoint slides and test bank.

Click here to contact us if you need more information on the trainer's package.

|

||

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List |

||

|

Copyright © 1995-2024. All rights reserved. |

||

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program. All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.