|

|

|

Home |

Consulting |

Training |

Expert Witness |

Failure Analysis |

Design Review |

Corrosion Test |

Corrosion Software |

Protective Coatings |

Materials Selection |

Cathodic Protection |

>>> |

|

Corrosion Inspection, Corrosion Testing

and Monitoring |

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

Why WebCorr

|

|

Course Overview |

|

Corrosion is a disease to materials just like

a disease to human beings. Some types or forms of corrosion can be prevented

through good practices in materials selection and design, while others can

be cured or controlled if diagnosed early.

Corrosion diagnosis involves a number of

destructive and non-destructive inspection and examination techniques such

as visual, NDT/NDE, inspection, chemical, electrochemical, mechanical,

metallurgical, and microstructural tests and analyses. Unexpected corrosion

failures can be avoided through

corrosion inspection, corrosion monitoring,

and corrosion testing. This corrosion short course aims to present to the technologists and engineers a dozen of

corrosion testing and monitoring techniques that can be used to solve many

of their most tedious and persistent corrosion problems. This corrosion course will

provide the participants with a thorough understanding of the basic

principles and the practical applications of some simple yet powerful

techniques in corrosion testing and monitoring. For each technique, a step

by step guide for performing the corrosion measurements will be described. This

5-day course

(with practical session) provides

an excellent avenue for corrosion practitioners, researchers, designers, technical

managers, inspection and maintenance engineers, quality control personnel and those

involved in failure analysis to update their appreciation of modern

techniques for corrosion testing and

monitoring. Corrosion is a disease to materials just like

a disease to human beings. Some types or forms of corrosion can be prevented

through good practices in materials selection and design, while others can

be cured or controlled if diagnosed early.

Corrosion diagnosis involves a number of

destructive and non-destructive inspection and examination techniques such

as visual, NDT/NDE, inspection, chemical, electrochemical, mechanical,

metallurgical, and microstructural tests and analyses. Unexpected corrosion

failures can be avoided through

corrosion inspection, corrosion monitoring,

and corrosion testing. This corrosion short course aims to present to the technologists and engineers a dozen of

corrosion testing and monitoring techniques that can be used to solve many

of their most tedious and persistent corrosion problems. This corrosion course will

provide the participants with a thorough understanding of the basic

principles and the practical applications of some simple yet powerful

techniques in corrosion testing and monitoring. For each technique, a step

by step guide for performing the corrosion measurements will be described. This

5-day course

(with practical session) provides

an excellent avenue for corrosion practitioners, researchers, designers, technical

managers, inspection and maintenance engineers, quality control personnel and those

involved in failure analysis to update their appreciation of modern

techniques for corrosion testing and

monitoring.

This corrosion short course can be taken as in-house

training course, online course and distance learning course worldwide. It can also be customized to meet the

specific needs of your organization. |

|

|

|

Course Outline |

|

This corrosion short course covers a wide range of corrosion testing and

monitoring techniques from conventional weight loss coupons, electrical

resistance (ER) and linear polarization resistance (LPR) to

advanced electrochemical impedance spectroscopy (EIS) for routine

applications such as rapid screening of corrosion inhibitors, materials

selection, failure analysis, corrosion rate measurement, life prediction,

evaluation of paints, coatings, electroplating, on-line monitoring of

industrial processes, determination of resistance to pitting and crevice

corrosion, and the degree of sensitization of stainless steels and alloys.

This course also covers six most commonly used non-destructive

techniques for corrosion inspection.

|

|

1. Basics

of Corrosion Measurements

1.1

Introduction

1.2

Corrosion and society

1.3

The

need for corrosion testing and monitoring

1.4

Terminology and conventions

1.5

Overview of

different forms of corrosion

2. Corrosion

Testing and Monitoring Techniques

2.1

Weight loss coupon

2.2

Electrical resistance (ER)

2.3

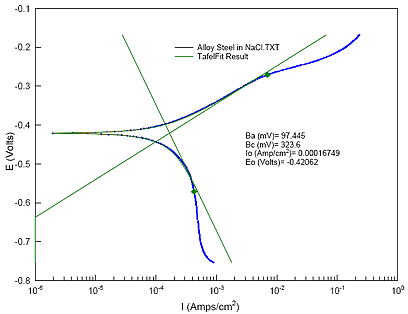

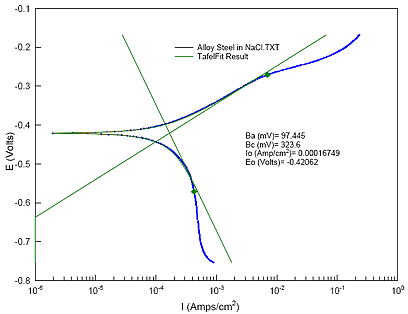

Principles of electrochemical methods and Tafel plot

2.4

linear polarisation resistance (LPR)

2.5

Potentiodynamic anodic polarisation

2.6

Cyclic polarisation for pitting test

2.7

Electrochemical potentiokinetic reactivation (EPR) for

sensitisation test

2.8

Other

techniques: electrochemical impedance spectroscopy (EIS),

electrochemical noise (EN),

zero-resistance ammetry (ZRA),

and hydrogen monitoring

3. Applications of Electrochemical Techniques

4. On-Line

Corrosion Monitoring

4.1 why

use on-line corrosion monitoring

4.2

direct methods of on-line corrosion monitoring

4.3

on-line monitoring system components and functions

4.4

principle on-line corrosion monitoring methods

4.5

where

&

when

to use it

4.6

how

much does it cost

5. Corrosion Inspection Techniques

5.1 Visual

Inspection

5.2 Liquid

Penetrant Inspection

5.3 Magnetic

Particle Inspection

5.4 Ultrasonic

Testing

5.5 Eddy Current

Testing

5.6 X-ray

Radiography

6. Software Solutions to Industrial

Corrosion: Overview of Corrosion Modeling and Corrosion

Prediction Software

-

ABC-Compass: Ammonium Bisulfide Corrosion Modeling and Life Prediction

-

ACE - Apps for Corrosion Engineers: A Collection of Essential

Corrosion Software Applications for Corrosion Engineers,

Corrosion Researchers, and Corrosion Technicians in

Laboratories and in Fields

-

ACMF-Compass: Modeling and Prediction of the Effects

of AC and Magnetic Field on Metal Corrosion

-

Atmosphere-Compass: Prediction and Modeling of Atmospheric

Corrosion of Metals and Alloys

-

CCC-Compass: Modeling and Prediction of Caustic Corrosion and Caustic

Stress Corrosion Cracking

-

CIPAL-Compass: Copper-Induced Pitting in Aluminium Alloys - Modeling, Life Prediction and Process Control

-

CO2Compass: Modeling and Prediction of Corrosion by Carbon

Dioxide (CO2), Hydrogen Sulfide (H2S), Acetic Acid (HAc), Elemental

Sulfur (S), and Mercury (Hg) in Oil and Gas Pipelines and Production

Tubing

-

Concrete-Compass: Concrete Corrosion Prediction and

Modeling

-

CP-Compass-Pipeline: Cathodic Protection Design Calculations, Verification, Assessment and Solution for Underground Pipelines

-

CP-Compass-Concrete: Design Calculations for Cathodic Protection of Reinforced Concrete Structures

-

CRA-Compass: Corrosion Modeling and Corrosion Prediction for

Corrosion Resistant Alloys - the Threshold Temperature and Chloride

Concentration for Pitting, Crevice Corrosion, and Stress Corrosion

Cracking (SCC)

-

CSR-Compass: Modeling and Remaining Life Prediction of Creep

and Stress Rupture of Boiler and Heater Tubes

-

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

-

Dew-Point-Compass: Prediction of Dew Point

Temperatures of Flue Gases and the Risk of Dew Point Corrosion

-

DWD-Compass: Modeling and Life Prediction of

Corrosion in Drinking Water Distribution Systems

-

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction

of Structures and Plant Assets

-

FAC-Compass:

Erosion Corrosion and Flow - Accelerated Corrosion Modeling, Life Prediction and Materials

Selection in Water-Steam Systems

-

FuelAsh-Compass: Fuel Ash Corrosion Modeling and Life Prediction of

Boiler and Heater Tubes

-

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

-

H2Compass: Modeling and Prediction of Low Temperature Hydrogen Damages

(Hydrogen Blistering, Hydrogen-Induced Cracking, Hydrogen Embrittlement) and High Temperature Hydrogen Attack (HTHA)

-

H2SO4-Compass: Corrosion Prediction and Materials Selection

Guide for H2SO4 Services

-

HCl-Compass: Corrosion Prediction and Materials

Selection Guide for HCl Services

-

ISO15156-Compass: Modeling and Prediction of in-situ

pH, Region of Environmental Severity, and Susceptibility to

Sulfide Stress Cracking (SSC) of Carbon and Low Alloy Steels

-

NAC-Compass: Modeling and Prediction of High Temperature Naphthenic Acid Corrosion

-

O2Compass: Modeling and Prediction of High Temperature Oxidation

-

OCTG-Compass: Corrosion Prediction and CRA Materials

Selection Guide for Oil and Gas Production Systems

-

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

-

PCW-Compass: Corrosion Prediction and Modeling in

Process Cooling Water Systems

-

SC-Compass: Stray Current

Corrosion and AC Corrosion - Identification, Assessment and

Prediction

-

S-Compass:

Modeling and Prediction of High Temperature Sulfidation/Sulfidic

Corrosion/H2-H2S Corrosion and Low Temperature Elemental Sulfur

Corrosion

-

Seawater-Compass: Seawater Corrosion Prediction for

Metals and Alloys

-

Shipwreck-Compass: Shipwreck Corrosion Modeling and Corrosion

Prediction

-

Soil-Compass: Soil Corrosion Prediction and Modeling for

Metals and Alloys

-

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

-

VPC-Compass-SE: Prediction and Modeling of Corrosion in Microelectronic Packages

|

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

|

Who Should Attend

This Corrosion Testing and Monitoring Course |

|

Corrosion practitioners, researchers, designers, technical managers, inspection

and maintenance engineers, quality control personnel and those involved in

failure analysis.

Successful completion of this corrosion course helps participants

prepare for their NACE certification examinations at the Corrosion Technician,

Corrosion Technologist and Senior Corrosion Technologist levels.

|

|

Registration

for This Corrosion Course |

|

Click

here to register for this corrosion course online,

or

Click

here to download this corrosion course brochure with

registration form in PDF format.

|

|

In-House Training Corrosion Courses and

On-Site Training Corrosion Courses |

|

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs. If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

There is no limit to the number of participants required for

in-house training corrosion courses. We conduct the in-house training

corrosion course at your company's premises worldwide, and at a time convenient to

your company.

Click

here to contact us

for a quotation for in-house training corrosion courses. |

|

Corrosion

Course-On-Demand |

|

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program. All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.

Click

here to contact us for a quotation. |

|

Online

Corrosion Courses and Distance Learning Corrosion

Courses |

|

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning. All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.

Click

here to to register an online corrosion short course. |

|

|

|

PowerPoint Slides and Test Banks for Trainers,

Instructors, Tutors, University Lecturers and Professors |

|

If you are involved in teaching or

training, you may wish to purchase a complete set of the trainer's

package for this training course. The trainer's

package comes complete with ready-to-use PowerPoint slides (fully

editable) and test bank (with answer keys). These ready-to-use

PowerPoint slides contain high quality color photographs, illustrations,

animations, audio and video clips. The test bank contains questions

in four categories: (1) true or false, (2)

multiple choice, (3) calculation, and (4) reasoning and open-ended

discussions. The trainer's package is suitable for in-house training and

university teaching (30 lecture hours). This is exactly the same package that WebCorr uses to deliver our

current training course.

The one-time lump sum fee allows your

organization to use the training package and also modify it. For

example, your organization may modify the course contents and

re-name/re-brand the course under your organizationís name. WebCorr only

retains the copyright of the original PowerPoint slides and test bank.

Click

here to contact us if you need more information on the trainer's package.

|

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

|

Home |

Contact Us |

Copyright

©

1995-2024. All rights reserved. |

Corrosion is a disease to materials just like

a disease to human beings. Some types or forms of corrosion can be prevented

through good practices in materials selection and design, while others can

be cured or controlled if diagnosed early.

Corrosion is a disease to materials just like

a disease to human beings. Some types or forms of corrosion can be prevented

through good practices in materials selection and design, while others can

be cured or controlled if diagnosed early.

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program. All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.